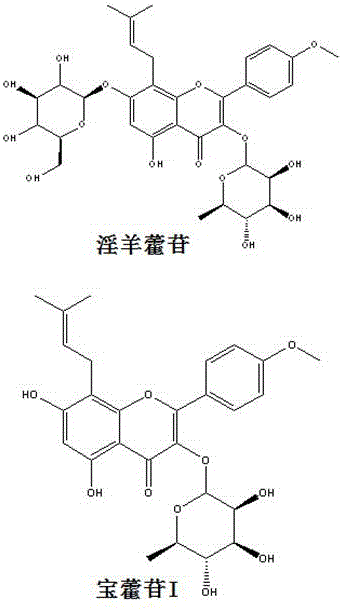

Method for obtaining baohuoside I by double-phase enzyme hydrolysis

A technology of baohuoside and enzymatic hydrolysis, applied in the field of medicine, can solve the problems of many operation steps, high cost, long cycle, etc., and achieve the effects of reducing side reactions, reducing preparation cost and reducing enzyme dosage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

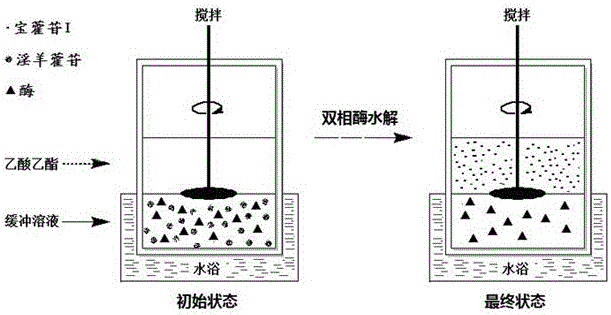

Method used

Image

Examples

Embodiment 1

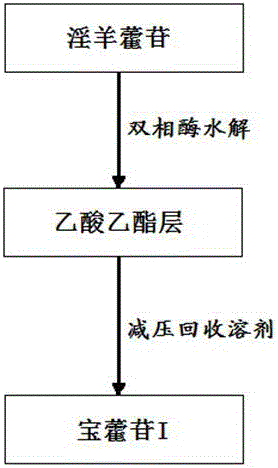

[0034] Weigh 0.1 g of icariin reference substance, add 200 mL of acetic acid-sodium acetate buffer solution (pH 3.5), mix well, and obtain icariin suspension. Add 4.0 g of β-glucosidase to the above icariin suspension and mix evenly, add 100 mL of ethyl acetate, adjust the stirring speed to 200 rpm, heat and react at 50°C for 0.5 h, cool, and divide the ethyl acetate solution, The solvent is recovered under reduced pressure to dryness, and the product of Baohuoside I is obtained. High performance liquid chromatograms before and after enzymatic hydrolysis Figure 4 As shown, it can be seen that icariin has been completely hydrolyzed into baohuoside I under the above conditions, and the yield is 100%.

Embodiment 2

[0036] Weigh 0.1 g of icariin reference substance, add 1000 mL of acetic acid-sodium acetate buffer solution (pH 5.5), mix well to obtain icariin suspension, and add β-glucose to the above icariin suspension Glucosidase 0.5 g, mix well, add 500 mL ethyl acetate, adjust the stirring speed to 50 rpm, heat and react at 40°C for 24 h, cool, separate the ethyl acetate solution, recover the solvent under reduced pressure to dryness, and obtain Baohuoside 1, yield 98.6%.

Embodiment 3

[0038] Weigh 0.1 g of icariin reference substance, add 200 mL of acetic acid-sodium acetate buffer solution (pH 5.0), mix well to obtain icariin suspension, and add β-glucose to the above icariin suspension Glucosidase 2 g, mix well, add 500 mL ethyl acetate, adjust the stirring speed to 150 rpm, heat at 50°C for 2 h, cool, separate the ethyl acetate solution, recover the solvent under reduced pressure to dryness, and obtain Baohuoside I , The yield is 100%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com