Recombinant engineered bacteria expressing glutamic acid decarboxylase on the surface, its construction method and application

A technology of glutamic acid decarboxylase and recombinant engineering bacteria, applied in the biological field, can solve the problems of cumbersome steps, insufficient apparent catalytic activity, influence of mass transfer resistance, etc., and achieves the effects of simple equipment, easy industrial application and simplified operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

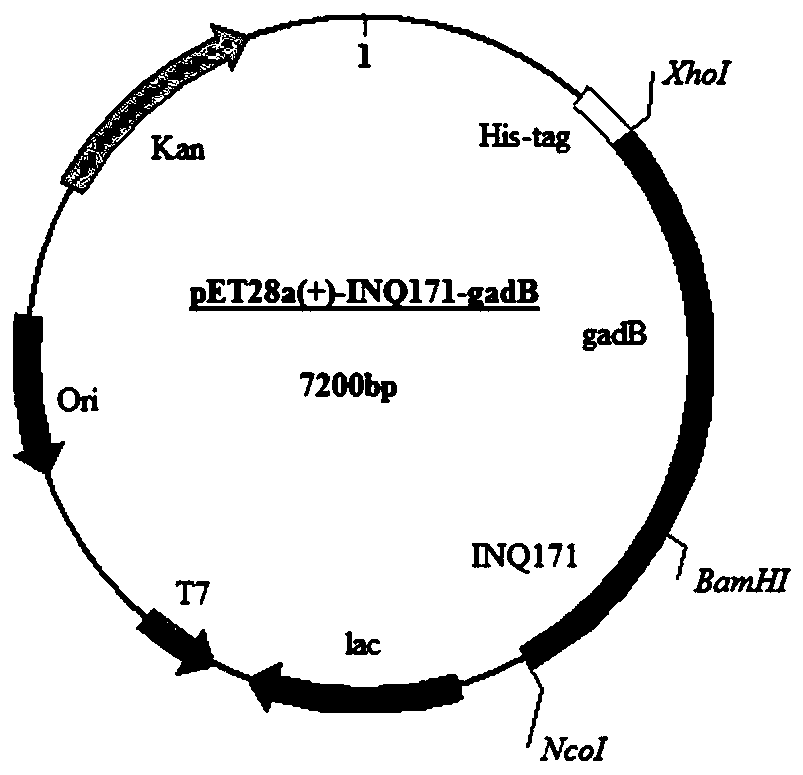

[0054] Example 1. Construction of recombinant plasmids for intracellular expression and surface display of glutamate decarboxylase in Escherichia coli

[0055] The construction process of the recombinant plasmid for intracellular expression and surface display of glutamate decarboxylase in E. coli is as follows figure 1 Shown. According to the β subtype gene sequence of E. coli GAD in GenBank (see SEQ ID No. 1 or GenBank No. EF551361.1), the primers gadB-F and gadB-R were designed and synthesized. The sequences are as follows:

[0056] gadB-F: 5’-AATTGGATCCATGGATAAGAAGCAAG-3’, the base corresponding to the underline indicates the BamHI restriction site;

[0057] gadB-R: 5'-AAGGCTCGAGGGTATGTTTAAAGCTG-3', the base corresponding to the underline indicates the XhoI restriction site.

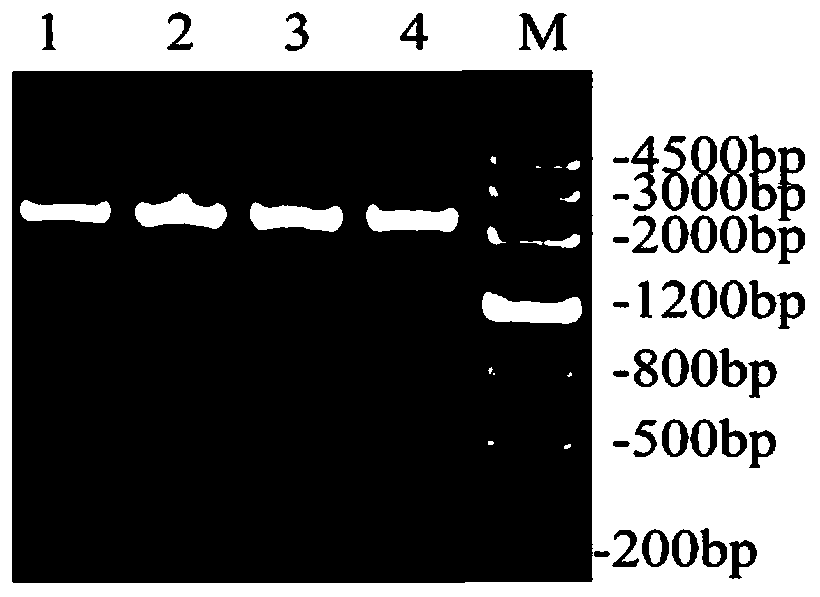

[0058] Using the total DNA of the E. coli strain as a template, PCR amplification was performed using a pair of gadB-F and gadB-R primers. The results are shown in figure 2 , Where 1 is PCR amplified gadB g...

Embodiment 2

[0065] Example 2 Expression of E. coli recombinant intracellular GAD enzyme and recombinant surface display GAD enzyme

[0066] The plasmids pET28a-gadB, pET28a-INP171-gadB and pET28a-INP224-gadB were respectively transformed into E. coli BL21(DE3) competent cells, coated with a plate containing 50ug / mL kanamycin LB solid medium, and inverted at 37°C Cultivate overnight. The single clones were picked separately, inoculated with LB liquid medium containing 50ug / mL kanamycin, and cultured in a constant temperature shaker at 37°C and 180 rpm for 10-12 hours. Take the culture solution to inoculate the fresh LB medium containing 50ug / mL kanamycin with 2% of the inoculum amount, and culture it with shaking in a shaker at 37℃ and 180rpm until the OD600 reaches 0.6-0.8, add the final concentration of 0.4mM IPTG, 16°C, 180rpm, continued shaking culture for 14-16h to induce the expression of GAD enzyme.

[0067] The cells were collected by centrifugation at 5000×g for 20 minutes at 4°C, wa...

Embodiment 3

[0069] Example 3 Analysis of the apparent enzyme activity of recombinant engineering bacteria containing intracellular expression of GAD enzyme and surface display expression of GAD enzyme

[0070] Take 10OD of the bacteria obtained in Example 2 and collect the bacteria by centrifugation. Resuspend in 0.2MpH4.0 citric acid-disodium hydrogen phosphate buffer containing 0.1ML-sodium glutamate and 10mMPLP, and react for 15min at 30°C and 180rpm / min. Centrifuge at 12000rpm for 30min, take 10ul of supernatant, and measure the amount of GABA produced by Berthelot colorimetric method.

[0071] It was determined that the apparent enzyme activity of the recombinant engineered bacteria expressing GAD enzyme on the surface was 200 U / g, while the apparent enzyme activity of the recombinant engineered bacteria expressing GAD enzyme in the cells was 170 U / g under the same culture conditions. The former is 17.65% higher than the latter. .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com