Spray type lubricating antirust agent and preparation method thereof

A lubricating rust-preventing and solvent technology, applied in lubricating compositions, petroleum industry, etc., can solve the problems of inability to wipe when wiping oil, shorten the service life of equipment, improve the rust rate of equipment, etc., and achieve good lubricating effect and good drying effect. , Environmentally friendly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

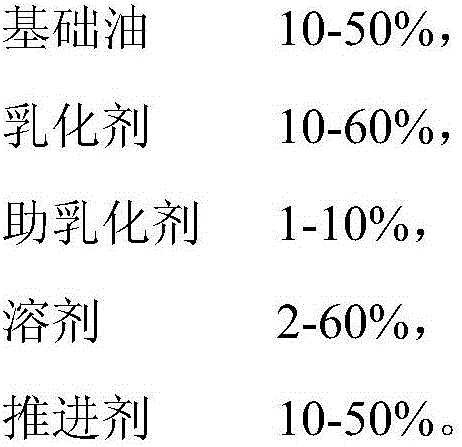

[0030] Described spray type lubricating antirust agent, the mass percentage of its each component is composed of:

[0031]

[0032] The base oil is medical mineral oil, the emulsifier is sorbitan fatty acid ester, the co-emulsifier is long-chain fatty acid, the solvent is ethanol, and the propellant is propane.

[0033] Mix the above components, stir evenly, and let it stand for 30 minutes to form a clear and transparent solution. Add the above mixture into a tinplate tank with a spray valve, and fill the tank with 25% propane gas at 0.6 MPa through the valve to obtain a spray-type lubricating rust preventive agent.

Embodiment 2

[0035] Described spray type lubricating antirust agent, the mass percentage of its each component is composed of:

[0036]

[0037] Wherein the base oil is medical mineral oil, the emulsifier is polyoxyethylene sorbitan fatty acid ester (5%) and triethanolamine oleate (5%), the co-emulsifier is a long-chain fatty alcohol, and the solvent is n-propanol, The propellant is n-butane.

[0038] Mix the above components, stir evenly, and let it stand for 30 minutes to form a clear and transparent solution. Add the above mixture into a tinplate tank with a spray valve, and fill the tank with 30% n-butane gas at 0.4 MPa through the valve to obtain a spray-type lubricating rust inhibitor.

Embodiment 3

[0040] Described spray type lubricating antirust agent, the mass percentage of its each component is composed of:

[0041]

[0042] Wherein the base oil is medical mineral oil, the emulsifier is triethanolamine oleate, the co-emulsifier is sodium lauryl sulfate (2%) and sodium dodecylbenzenesulfonate (3%), and the solvent is sec-butanol, The propellant is isobutane.

[0043] Mix the above components, stir evenly, and let it stand for 30 minutes to form a clear and transparent solution. Add the above mixture into a tinplate tank with a spray valve, and fill the tank with 15% isobutane gas at 0.5 MPa through the valve to obtain a spray-type lubricating rust preventive agent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com