Photoelectric chemical battery electrode and preparation method and application thereof

A technology of photoelectrochemical cells and electrodes, which is applied in the field of new materials and new energy sources, can solve the problems of limiting the effective collection of photogenerated carriers, high equipment requirements, complex preparation processes, etc., and achieves short preparation process time and accelerated transfer Speed, non-toxic effect of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

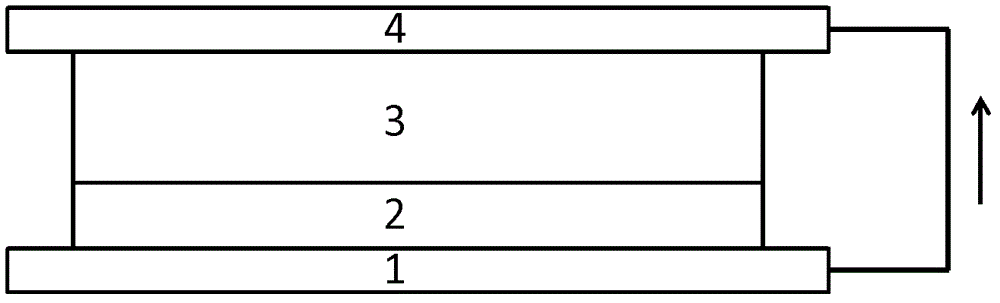

Image

Examples

Embodiment 1

[0037] Clean the FTO conductive glass, then sonicate it in deionized water, ethanol and acetone for 30 minutes, and dry it for later use;

[0038] Prepare sodium acetate solution and copper acetate solution respectively, then mix the two and stir evenly, wherein the molar ratio of sodium acetate and copper acetate is 5:1; add acetic acid to adjust the pH value to about 5.4;

[0039] Using the above solution as the electrolyte, the cuprous oxide film containing metallic copper particles is electrochemically deposited on the FTO conductive glass: the FTO conductive glass is used as the working electrode, the platinum wire is used as the counter electrode, and the saturated calomel electrode is used as the reference electrode. Potential mode, keep the potential at -245mV, react at 60°C for 20min;

[0040] Take out the electrode sample, wash it three times with deionized water or absolute ethanol, and then dry it at 60°C until all the water or ethanol volatilizes to obtain the pho...

Embodiment 2

[0046] The only difference between this embodiment and embodiment 1 is that the electrodeposition time is replaced by 60 min from 20 min, and the rest of the content is the same as that described in embodiment 1.

[0047] The film thickness of the photoelectrochemical cell electrode prepared in this embodiment is about 15 μm.

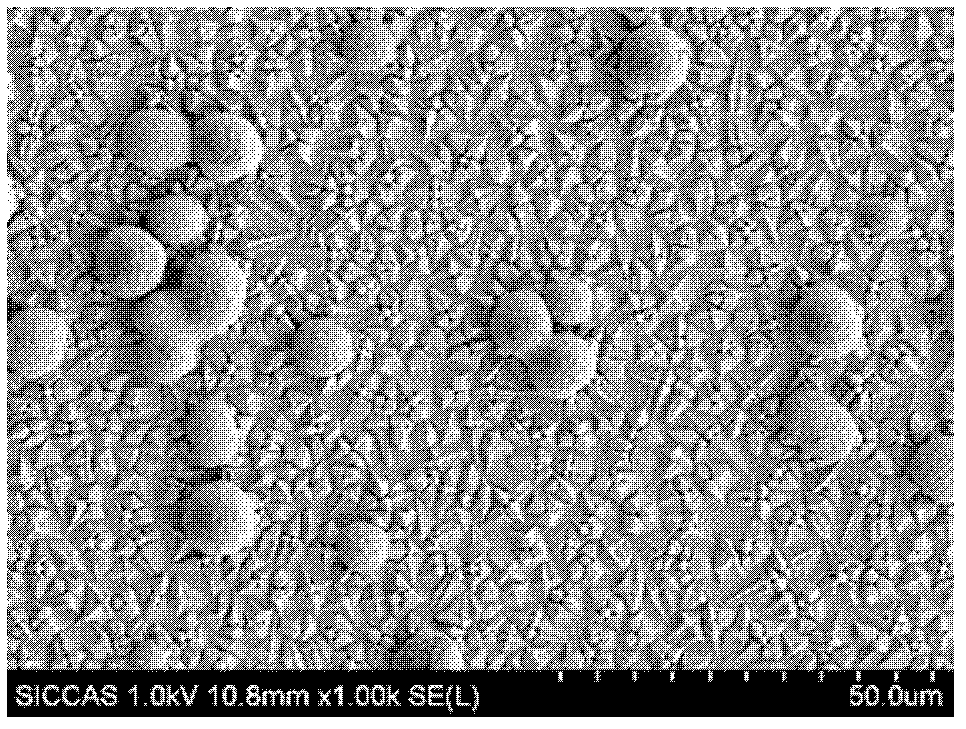

[0048] Figure 5 It is the SEM picture of the electrode sample that the present embodiment makes, by Figure 5 It can be seen that the increase of deposition time will not only increase the thickness of the film, but also increase the number of metal particles attached to the surface of the film.

[0049] Figure 6 It is that the photoelectrochemical cell assembled in the present embodiment has an intensity of 100mV / cm 2 The current-voltage characteristic curve of the AM1.5G simulated sunlight test. During the test, use a light-shielding plate with a hole in the center to determine that the effective area of the battery is 0.12cm 2 ,Depend on Figu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com