Absorbable dura mater and preparation method thereof

A dura mater and gelatin technology, applied in prosthesis, tissue regeneration, medical science, etc., can solve the problems of prolonging postoperative recovery of patients, unable to provide cell adhesion, proliferation and differentiation, avoiding manual suture and shortening clinical operation time. , enhance the regeneration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

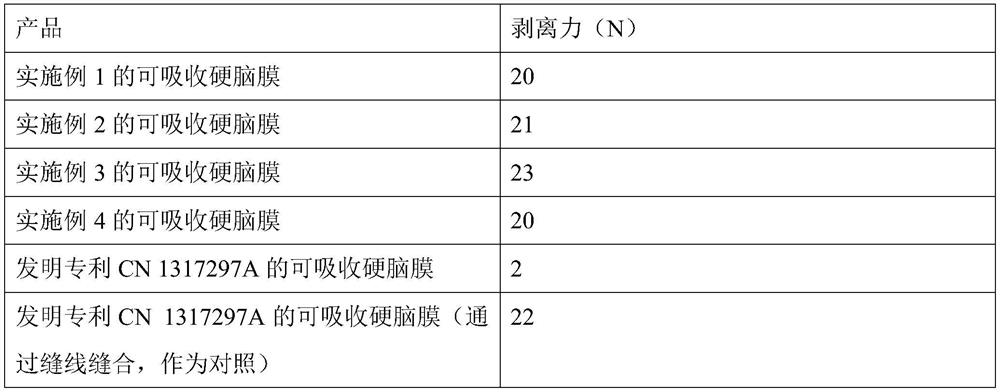

Examples

Embodiment 1

[0033] An absorbable dura mater, including a hydrophilic layer and a hydrophobic layer. The three-dimensional structure formed by the cross-linking and curing of acrylated gelatin and acrylate-polyethylene glycol-N hydroxysuccinimide ester is used as the hydrophilic layer. A dense film formed by absorbent polyester acts as a hydrophobic layer.

[0034] The preparation method of the absorbable dura mater described in this embodiment comprises the following steps:

[0035] S1. Add acrylated gelatin, acrylate-polyethylene glycol-N hydroxysuccinimide ester and photoinitiator into 400 parts by mass of deionized water according to parts by mass of 30, 20, and 0.5 parts by mass, stir and dissolve, and prepare A solution;

[0036] S2. Transfer the A solution to a flat mold C with a diameter of 15 cm and a thickness of 2 mm, and irradiate with a curing lamp with a wavelength of 420 nm to cross-link and solidify the A solution to form a hydrogel A;

[0037] S3. Freeze-drying the hydrog...

Embodiment 2

[0042] This embodiment is based on embodiment 1, and the difference with embodiment 1 is:

[0043]The acrylated gelatin is butyl acrylated gelatin, and the acrylate-polyethylene glycol-N hydroxysuccinimide ester is methacrylate-PEG 1200 -N hydroxysuccinimide ester, the absorbable polyester is racemic polylactic acid, and the initiator is blue light initiator phenyl-2,4,6 trimethylbenzoyl lithium phosphite (LAP).

[0044] The mass ratio of acrylated gelatin, acrylate-polyethylene glycol-N hydroxysuccinimide ester photoinitiator and deionized water in step S1 is: 20:8:0.05:100;

[0045] The mass ratio of absorbable polyester to methylene chloride in step S4 is 40:200.

Embodiment 3

[0047] This embodiment is based on embodiment 1, and the difference with embodiment 1 is:

[0048] The ethacrylated gelatin, the acrylate-polyethylene glycol-N hydroxysuccinimide ester is methacrylate-PEG 2000 -N hydroxysuccinimide ester, the absorbable polyester is a lactide / glycolide copolymer, and the initiator is a visible light initiator camphorquinone (CQ).

[0049] The mass ratio of acrylated gelatin, acrylate-polyethylene glycol-N hydroxysuccinimide ester photoinitiator and deionized water in step S1 is: 45:30:0.2:350;

[0050] The mass ratio of absorbable polyester to methylene chloride in step S4 is 15:80.

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com