Water-based white primer for bamboo-wood ware product

A white primer and product technology, applied in coatings, polyurea/polyurethane coatings, etc., can solve the problems of low organic volatile content in water-based white primers, and achieve good compactness, strong adhesion, and good antibacterial properties. The effect of antifungal properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

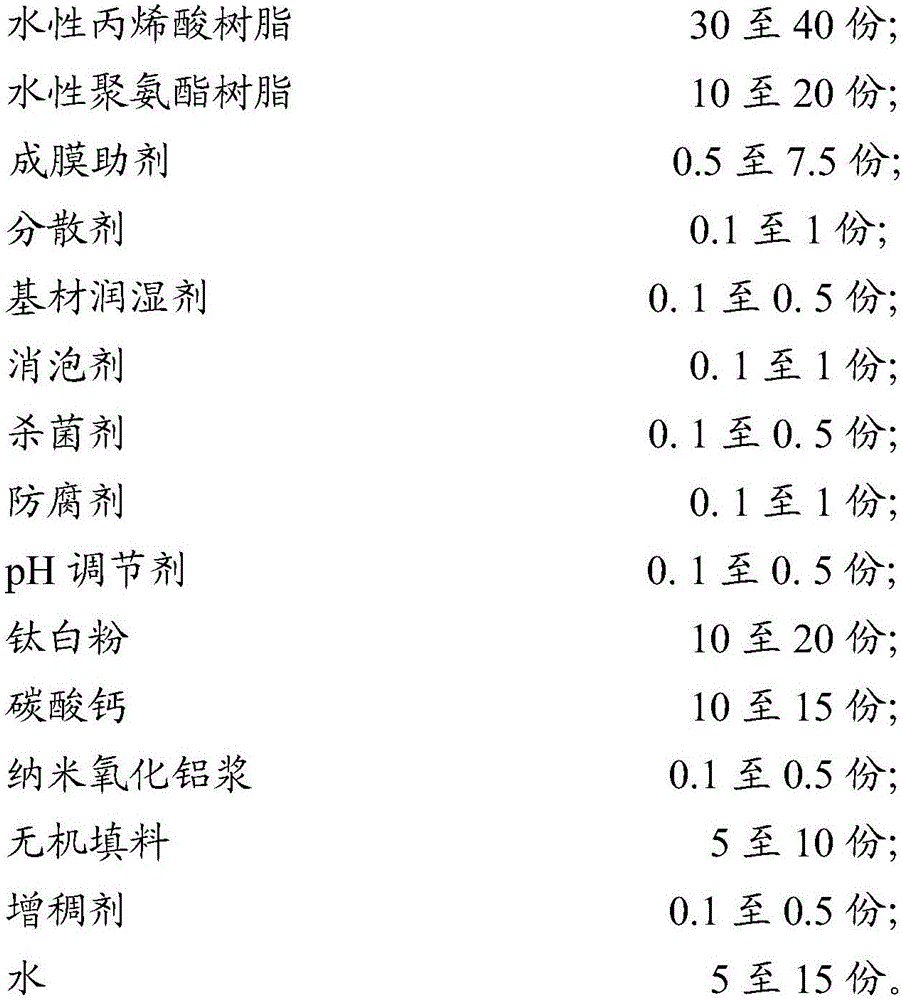

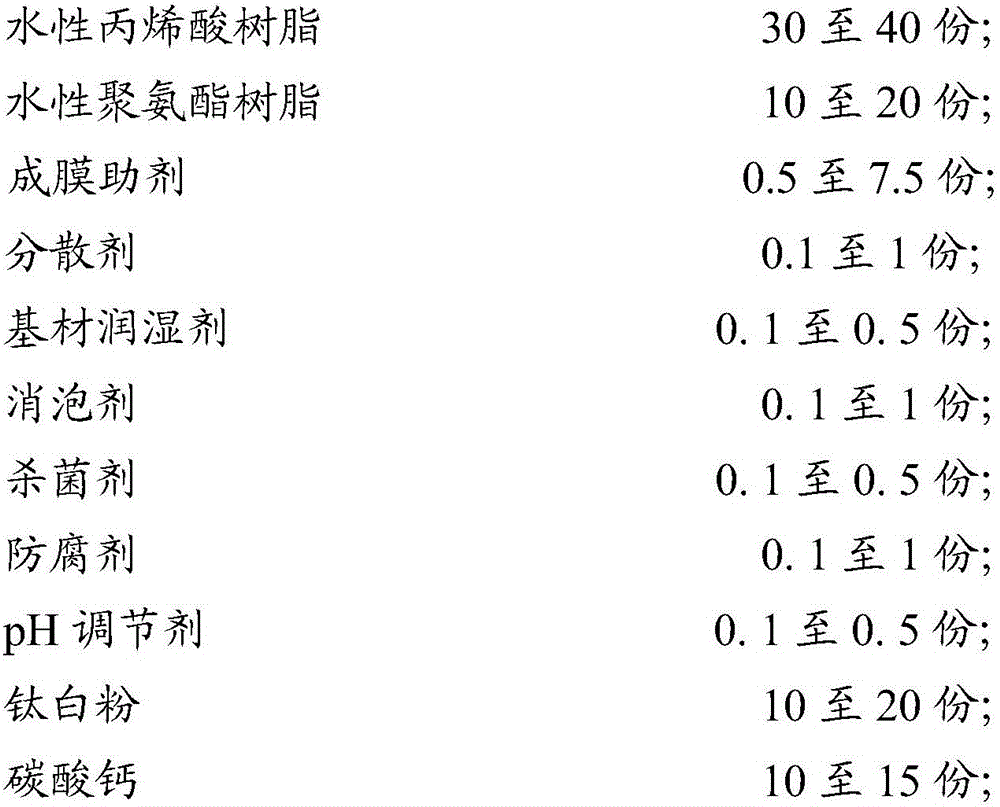

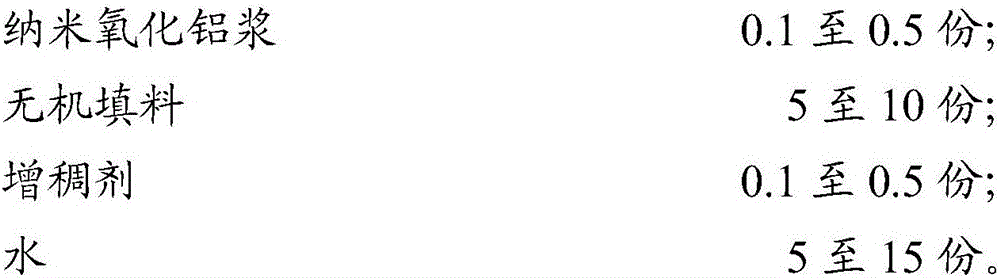

[0048] Material preparation: 350 kg of water-based acrylic resin, 150 kg of water-based polyurethane resin, 25 kg of coalescent, 8 kg of dispersant, 3 kg of substrate wetting agent, 7 kg of defoamer, and 2 kg of bactericide , 5 kg of preservative, 4 parts of pH regulator, 150 kg of titanium dioxide, 120 kg of calcium carbonate, 3 kg of nano-alumina paste, 80 kg of inorganic filler, 2 kg of thickener, and 103 kg of water.

[0049] Among them, the water-based acrylic resin was purchased from Dow Chemical, and the product brand was DOW3311; the water-based polyurethane resin was purchased from Wanhua Chemical, and the product brand was 4210; the film-forming aid is dipropylene glycol butyl ether; the dispersant is purchased from BYK Chemicals, and the product brand is BYK190; the substrate wetting agent is purchased from German EVONIK company, and the product brand is TEGO270; the defoamer is purchased from German Tego Company , the product grade is TEGO825; the fungicide is pur...

Embodiment 2

[0051] Material preparation: 350 kg of water-based acrylic resin, 150 kg of water-based polyurethane resin, 25 kg of coalescent, 8 kg of dispersant, 3 kg of substrate wetting agent, 7 kg of defoamer, and 2 kg of bactericide , 5 kg of preservative, 4 parts of pH regulator, 150 kg of titanium dioxide, 120 kg of calcium carbonate, 3 parts of nano-alumina paste, 80 kg of inorganic filler, 3 parts of thickener, and 103 kg of water.

[0052] Among them, the water-based acrylic resin was purchased from Dow Chemical, and the product brand was DOW3311; the water-based polyurethane resin was purchased from Wanhua Chemical, and the product brand was 4210; the film-forming aid is dipropylene glycol butyl ether; the dispersant is purchased from TEGO Company in Germany, and the product brand is TEGO Dispers 760W; the substrate wetting agent is purchased from BYK, and the product brand is BYK345; the defoamer is purchased from BYK Chemistry, product grade is BYK-024; Fungicide is purchased ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com