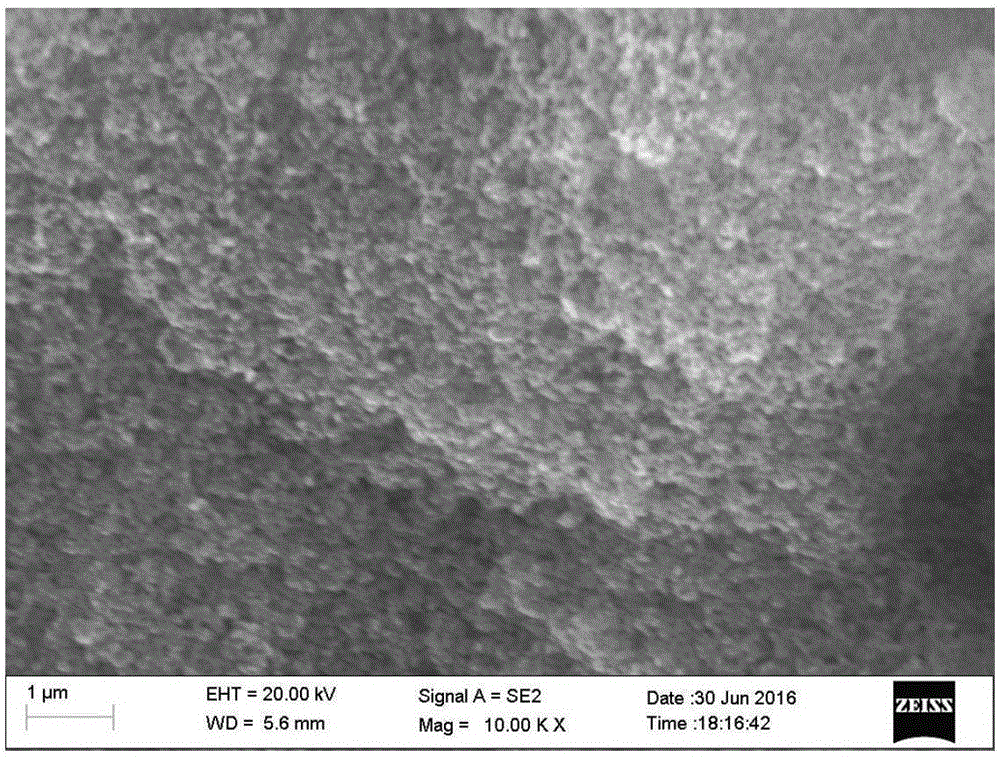

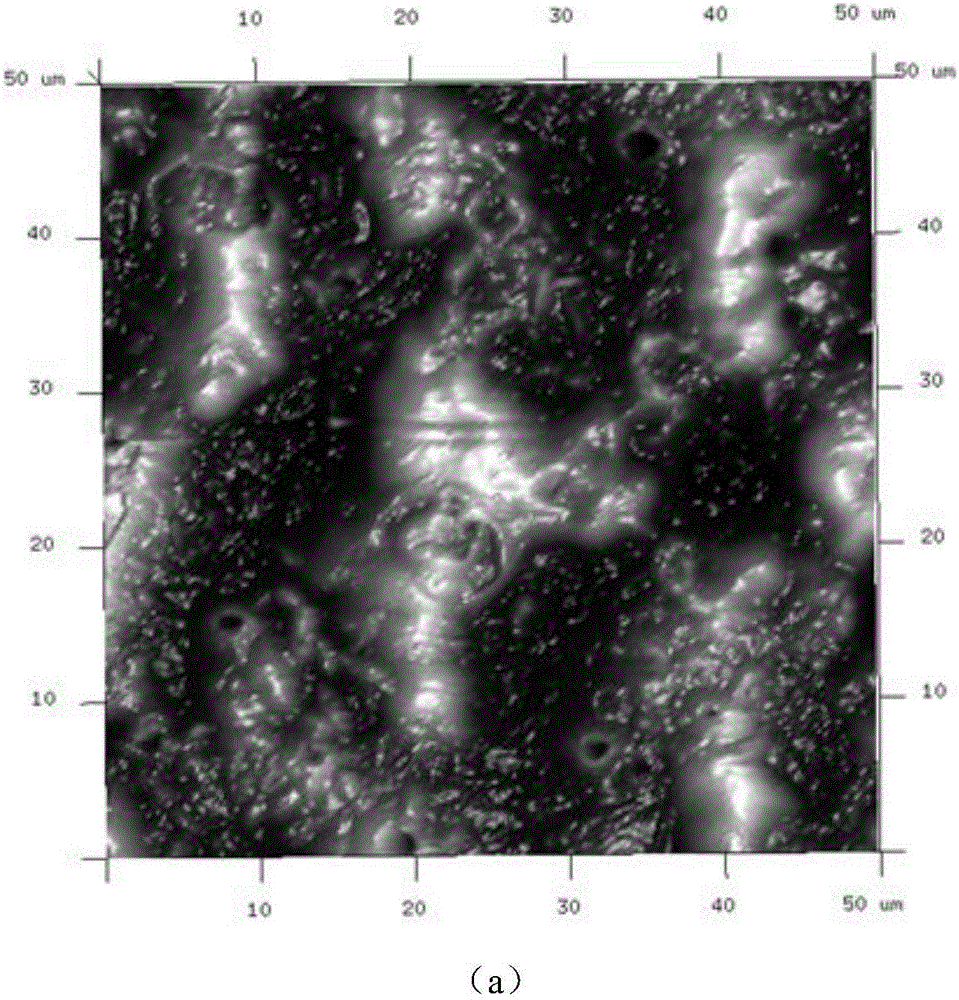

Integrated wear-resistant superamphiphobic coating and preparation method thereof

A super-amphiphobic coating technology, applied in coatings, anti-corrosion coatings, polyurea/polyurethane coatings, etc., can solve the problems of high process requirements of super-amphiphobic coatings, poor wear resistance of coatings, and no self-healing properties. To achieve the effect of strong durability, improved bonding performance, and simple use method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] Embodiment 1: general-purpose integrated wear-resistant superamphiphobic coating (polystyrene) preparation process, the steps are as follows:

[0051] 1) Nano-scale silica and 1H, 2H, 2H-perfluorooctylmethyldichlorosilane are mixed at a mass ratio of 1:1, and acetone is added to dissolve into a gel. The mass of nano-scale silica and acetone Ratio of 2:4, ultrasonic dispersion for 15 minutes;

[0052] 2) Mix polydimethylsiloxane and tert-butyl acetate at a mass ratio of 1:4, stir magnetically, heat at 40°C, stir at 900r / min, and stir for 0.8h;

[0053] 3) Add BYK3700 nano-auxiliary to propylene glycol methyl ether acetate, the mass ratio of propylene glycol methyl ether acetate and BYK3700 nano-auxiliary is 1:5, magnetic stirring, heating temperature is 80°C, stirring speed is 900r / min, stirring for 1h ;

[0054] 4) Put the substances obtained in the above three steps at a weight ratio of 2:5:15, put the above three substances into a three-necked bottle and mix them, i...

Embodiment 2

[0062] Embodiment 2: general-purpose integrated wear-resistant superamphiphobic coating (polystyrene) preparation process, the steps are as follows:

[0063] The technical solution adopted by the present invention to achieve the above object is to provide a general-purpose integrated wear-resistant superamphiphobic coating preparation process, including the following steps:

[0064] 1) Nano-scale silica and hexamethylenedisiloxane are mixed in a mass ratio of 1:2, and acetone is added to dissolve into a gel. The mass ratio of nano-scale silica to acetone is 2:9, and ultrasonic Disperse for 10 minutes;

[0065] 2) Mix polydimethylsiloxane and tert-butyl acetate at a mass ratio of 1:2, stir magnetically, heat at 60°C, stir at 800r / min, and stir for 0.5h;

[0066] 3) Add BYK3700 nano additives to propylene glycol methyl ether acetate, the mass ratio of propylene glycol methyl ether acetate and BYK3700 nano additives is 1:6, magnetic stirring, heating temperature 60°C, stirring s...

Embodiment 3

[0074] Embodiment 3: general-purpose integrated wear-resistant super-amphiphobic coating (EPDM rubber) preparation process, the steps are as follows:

[0075] The technical solution adopted by the present invention to achieve the above object is to provide a general-purpose integrated wear-resistant superamphiphobic coating preparation process, including the following steps:

[0076] 1) Mix nanoscale titanium dioxide with 1H, 2H, 2H-perfluorooctylmethyldichlorosilane in a mass ratio of 1:3, add acetone to dissolve into a colloid, and the mass ratio of nanoscale silicon dioxide to acetone is 5:19, ultrasonic dispersion for 15 minutes;

[0077] 2) Mix polydimethylsiloxane and tert-butyl acetate in a mass ratio of 1:4, stir magnetically, heat at 75°C, stir at a rate of 1100r / min, and stir for 1.5h;

[0078] 3) Add BYK3700 nano additives to N-methylpyrrolidone, the mass ratio of N-methylpyrrolidone and BYK3700 nano additives is 1:4, magnetic stirring, heating temperature 90 ° C, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com