A high fog surface halogen-free flame-retardant thermoplastic elastomer for wire and cable and its preparation method

A thermoplastic elastomer, wire and cable technology, used in plastic/resin/wax insulators, circuits, insulators, etc., can solve the problems of poor fogging effect of halogen-free flame retardant TPE cable materials, and improve the fogging effect. Good touch, anti-aging touch effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

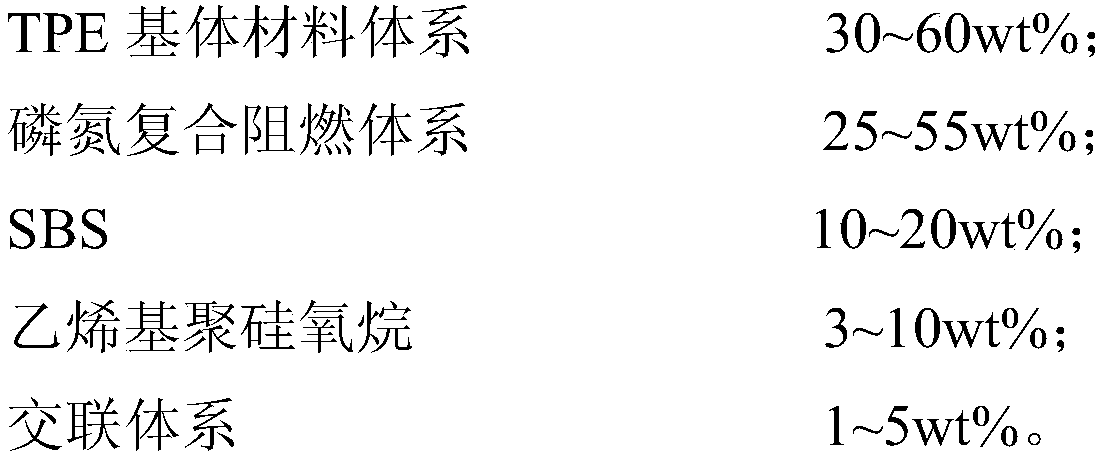

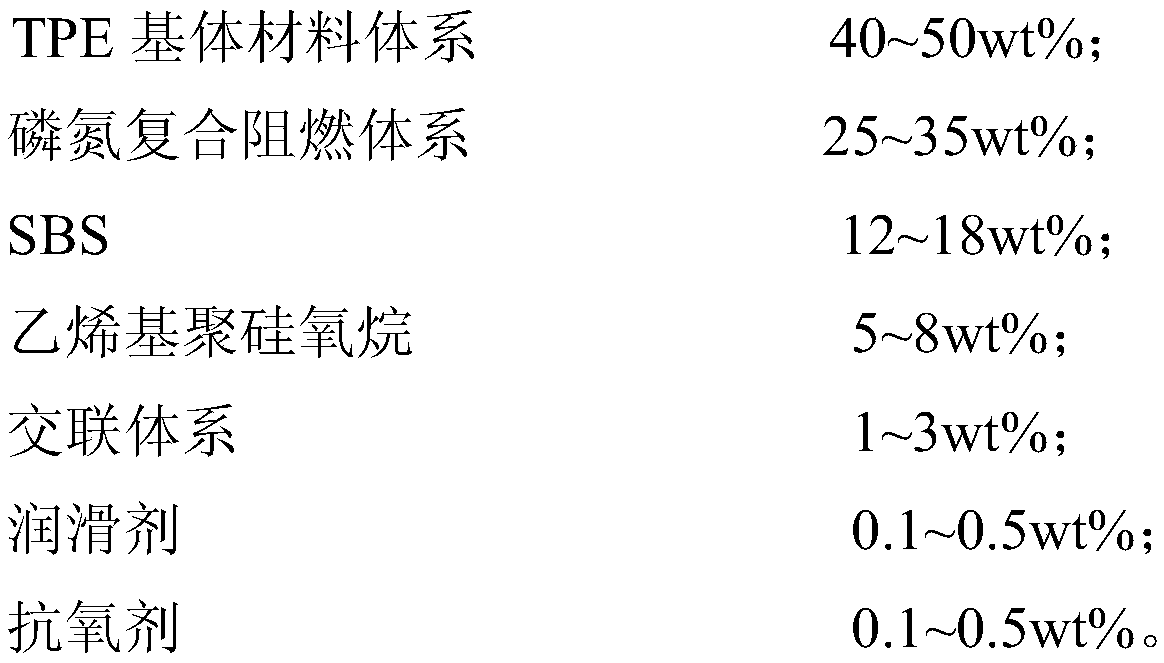

Method used

Image

Examples

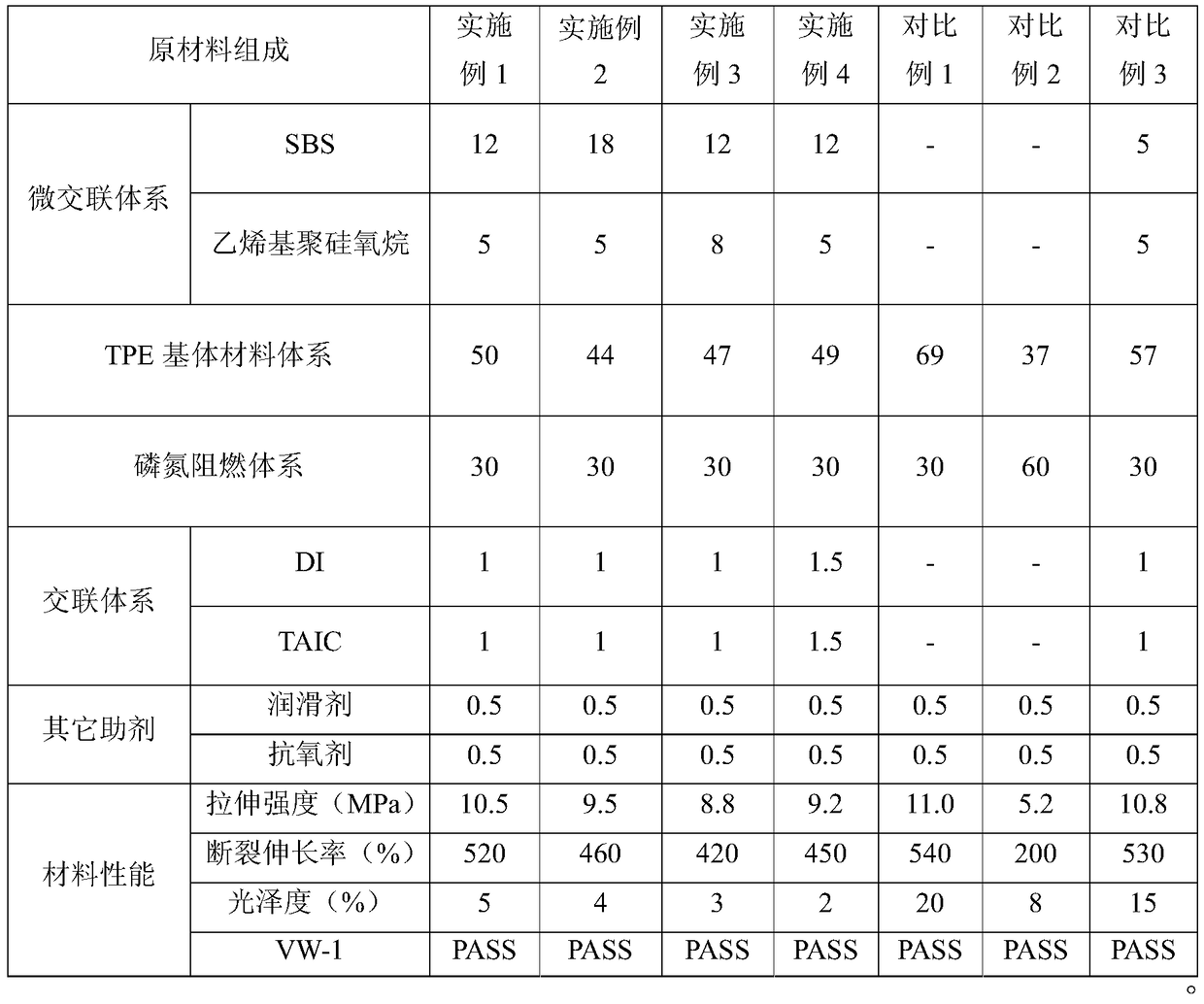

Embodiment 1

[0047] (1) Oil-extending and plasticizing of SBS

[0048] Add SBS, softener vinyl polysiloxane (XHG-206-60000) and cross-linking system into the internal mixer, set the temperature of the internal mixer to 200°C, and the internal mixing time should not be less than 3 hours to complete the plasticization of SBS and mixing with softeners;

[0049] The crosslinking system is composed of di-tert-butyl peroxide and triallyl isocyanurate in a mass ratio of 1:1.

[0050] (2) Mixing of high-matte halogen-free flame-retardant TPE system

[0051] Add TPE matrix material system, phosphorus nitrogen flame retardant system and other additives, and mix the materials evenly under high-speed stirring;

[0052] The TPE matrix material system is obtained by mixing SEBS (Kraton G1651), 68# white oil and polypropylene (T30S) in a weight percentage of 50:30:20;

[0053] The phosphorus-nitrogen flame retardant system is obtained by mixing aluminum diethyl hypophosphite, polyphenylene oxide (PPO)...

Embodiment 2

[0061] The implementation process is the same as in Example 1, except that the ratio of SBS and vinyl polysiloxane is adjusted, and the ratio of SBS is increased. See Table 1 for other materials and their proportions, and see Table 1 for the performance test results of the obtained materials.

Embodiment 3

[0063] The implementation process is the same as in Example 1, except that the ratio of SBS and vinyl polysiloxane is adjusted, and the ratio of vinyl polysiloxane is increased. See Table 1 for other materials and their proportions, and see Table 1 for the performance test results of the obtained materials.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com