Composite material comprising low-cost high-efficiency broad-spectrum antibacterial polypropylene functional master batch and preparation method thereof

A technology of antibacterial polypropylene and functional masterbatch, applied in the field of polypropylene, can solve the problems of lack of strong market competitiveness, antibacterial properties of antibacterial agents, and difficult active antibacterial groups, etc., to improve compatibility and antibacterial effect. Excellent, material cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

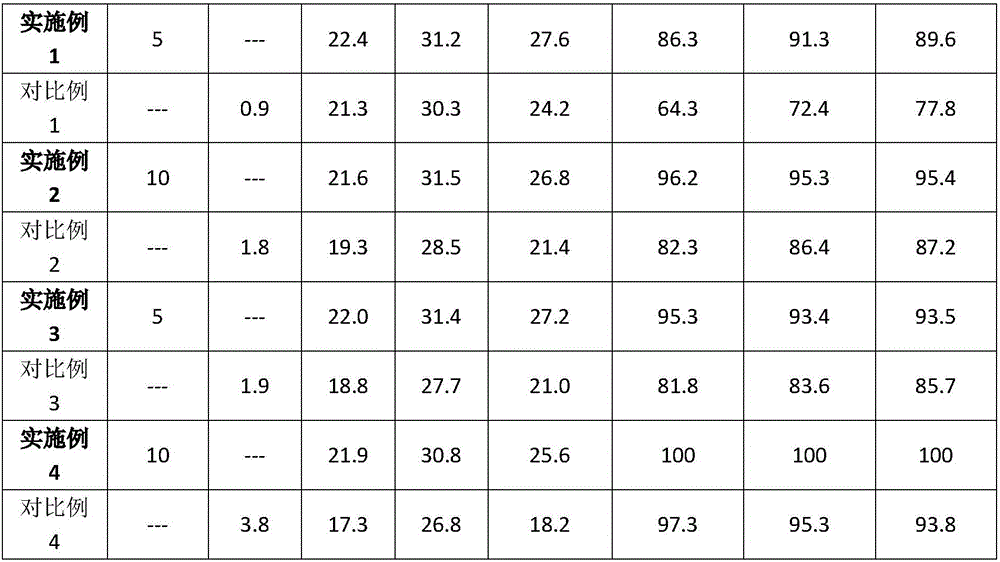

Embodiment 1

[0040] (1) Preparation of antibacterial functional masterbatch:

[0041] i. Surface modification of titanium dioxide-loaded silver antimicrobial agent

[0042] According to parts by weight, 90 parts of titanium dioxide silver-loaded antibacterial agent is dried, and 10 parts of silane surface modifier are added into a high-speed mixer and prepared by high-speed mixing.

[0043] ii. Preparation of low-cost, high-efficiency, broad-spectrum antibacterial functional masterbatch

[0044]In parts by weight, high flow rate polypropylene with a flow rate of 560g / 10min: 78 parts of HL50BFB, 20 parts of modified titanium dioxide silver-loaded antibacterial agent, 0.5 part of antioxidant DSTP: 1010; other additives: 168 auxiliary antioxidant 1.5 parts of additives are added to the mixer and mixed evenly, then added to the twin-screw extruder, melted, extruded, cooled, and pelletized by the twin-screw extruder to prepare. At 230°C and 2.16Kg, the flow rate of the masterbatch was measure...

Embodiment 2

[0054] (1) Preparation of antibacterial functional masterbatch:

[0055] i. Surface modification of titanium dioxide-loaded silver antimicrobial agent

[0056] According to parts by weight, 90 parts of titanium dioxide silver-loaded antibacterial agent is dried, and 10 parts of silane surface modifier are added into a high-speed mixer and prepared by high-speed mixing.

[0057] ii. Preparation of low-cost, high-efficiency, broad-spectrum antibacterial functional masterbatch

[0058] In parts by weight, high flow rate polypropylene with a flow rate of 560g / 10min: 78 parts of HL50BFB, 20 parts of modified titanium dioxide silver-loaded antibacterial agent, antioxidant: 0.5 part of 1010; other additives: 168 auxiliary antioxidant auxiliary Add 1.5 parts of the agent into the mixer and mix evenly, then add it into the twin-screw extruder, melt, extrude, cool, and pelletize through the twin-screw extruder to prepare. At 230°C and 2.16Kg, the flow rate of the masterbatch was measu...

Embodiment 3

[0068] (1) Surface modification of titanium dioxide-loaded silver antimicrobial agent:

[0069] i. Surface modification of titanium dioxide-loaded silver antimicrobial agent

[0070] In parts by weight, 95 parts of titanium dioxide silver-loaded antimicrobial agent is dried, and 5 parts of silane surface modifier are added into a high-speed mixer and prepared by high-speed mixing.

[0071] ii. Preparation of low-cost, high-efficiency, broad-spectrum antibacterial functional masterbatch

[0072] In parts by weight, high flow rate polypropylene with a flow rate of 560g / 10min: 58 parts of HL50BFB, 40 parts of modified titanium dioxide silver-loaded antibacterial agent, antioxidant: 0.5 part of 1010; other additives: 168 auxiliary antioxidant auxiliary Add 1.5 parts of the agent into the mixer and mix evenly, then add it into the twin-screw extruder, melt, extrude, cool, and pelletize through the twin-screw extruder to prepare. At 230°C and 2.16Kg, the flow rate of the masterbat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com