Photochromic lens treatment method

A processing method and technology of color-changing lenses, which are applied in the directions of glasses/goggles, optics, optical components, etc., can solve the problems of low timeliness of color-changing fading and insufficient color-changing depth of lenses.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

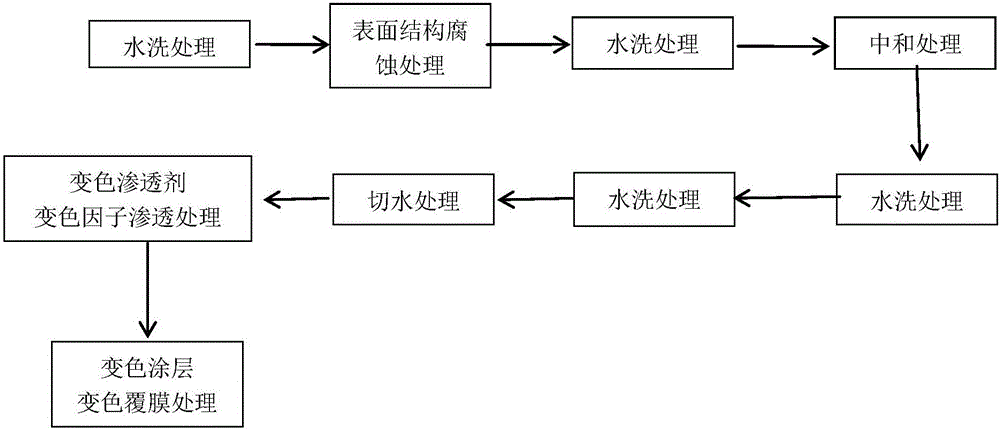

[0057] see figure 1 , the invention discloses a treatment method for photochromic lenses, the treatment method comprising the following steps:

[0058] [Step S1] Environmental conditions: temperature 20-30°C, humidity 55-65% RH, soak the lens in chemical solution A and chemical solution B under different conditions and wash with RO water or pure water to form a uniform surface of the lens Microporous structure; specifically includes:

[0059] Step S11: Water washing step; use RO water to soak the lens in the first tank of the processing equipment, the temperature of the RO water is 35-75°C, the immersion time is 5-30 minutes, and the composite frequency is passed by a voltage of 220V and a power of 500w Ultrasonic irradiation;

[0060] Step S12: Corrosion step; immerse the lens treated in step S11 in the second tank of the processing equipment with chemical solution A, the temperature is 35-75°C, and the immersion time is 5-30 minutes; the chemical solution A includes a mass...

Embodiment 2

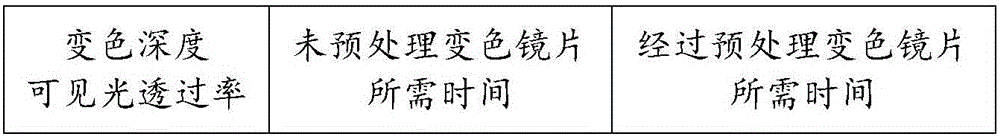

[0076] The method of the present invention forms a uniform honeycomb structure on the surface of the lens through a special process: first use a special ultrasonic device to clean the surface of the lens with a special chemical solution A to form a uniform honeycomb structure, and then use a special chemical solution B to form a uniform honeycomb structure. To neutralize the chemical solution A remaining on the surface of the lens, the following must be controlled during this process: the energy value of the ultrasonic wave, the preparation of the chemical solution A, the temperature and time of operation, and the conductivity of pure water must reach 16MΩ. cm or more), the purpose and advantage of this is that, while ensuring that the surface quality of the lens will not be damaged, it is beneficial to accommodate more discoloration factors per unit area of the surface of the lens, enhancing the discoloration effect of the lens, and at the same time having enough space Provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com