Polyurethane antitheft door plate

A technology of anti-theft door panels and polyurethane, which is applied in polyurea/polyurethane coatings, anti-theft, door leaves, etc., can solve the problems of anti-theft doors such as rust, poor compressive strength, and many solder joints, and achieve sound insulation, uniform filling, The effect of increasing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

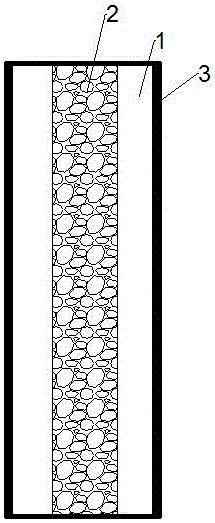

[0020] Polyurethane anti-theft door panels, such as figure 1 As shown, it includes an outer plate 1 and an inner filling layer 2, the inner filling layer 2 is polyurethane foam, the surface of the outer plate 1 is sprayed with a polyurethane layer 3, the outer plate 1 is a steel plate, and the thickness of the outer plate 1 is 3cm.

[0021] Polyurethane foam is polyurethane rigid foam. The polyurethane rigid foam comprises the following components and is prepared by high-pressure foaming: in parts by weight, 90 parts of diphenylmethane diisocyanate, 100 parts of hexamethylene diisocyanate, sucrose and glycerin as initiators and cyclic 100 parts of polyether polyols were obtained through addition reaction of ethylene oxide, 80 parts of polyether polyols, 12 parts of foaming agent and foam 3 parts of stabilizer.

[0022] The polyurethane layer consists of a two-component polyurethane coating, and the surface roughness of the polyurethane layer is 80 μm. The ratio of the thic...

Embodiment 2

[0024] Polyurethane anti-theft door panels, such as figure 1 As shown, it includes an outer plate 1 and an inner filling layer 2, the inner filling layer 2 is polyurethane foam, the surface of the outer plate 1 is sprayed with a polyurethane layer 3, the outer plate 1 is a stainless steel plate, and the thickness of the outer plate 1 is It is 1cm.

[0025] Polyurethane foam is polyurethane rigid foam, and polyurethane rigid foam comprises the following components and is made through high-pressure foaming: by weight, 100 parts of diphenylmethane diisocyanate, 80 parts of hexamethylene diisocyanate, sucrose and glycerin 150 parts of polyether polyol, 15 parts of foaming agent and 4 parts of foam stabilizer are prepared by addition reaction of initiator and ethylene oxide.

[0026] The polyurethane layer consists of a two-component polyurethane coating, and the surface roughness of the polyurethane layer is 120 μm. The ratio of the thickness of the outer plate to the thickness ...

Embodiment 3

[0028] Polyurethane anti-theft door panels, such as figure 1 As shown, it includes an outer layer plate 1 and an inner filling layer 2, the inner filling layer 2 is polyurethane foam, the surface of the outer layer plate 1 is sprayed with a polyurethane layer 3, the outer layer plate 1 is an aluminum alloy plate, and the outer layer plate 1 The thickness is 2cm.

[0029] Polyurethane foam is polyurethane rigid foam, and polyurethane rigid foam comprises the following components and is made through high-pressure foaming: by weight, 80 parts of diphenylmethane diisocyanate, 100 parts of hexamethylene diisocyanate, sucrose and glycerin 100 parts of polyether polyols were prepared by addition reaction with ethylene oxide as the initiator, 100 parts of polyether polyols were prepared by addition reaction of xylitol and glycerin as initiators with ethylene oxide, and Foam agent 15 parts and foam stabilizer 5 parts.

[0030] The polyurethane layer consists of two-component polyuret...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com