Method for extracting longan pulp polysaccharide

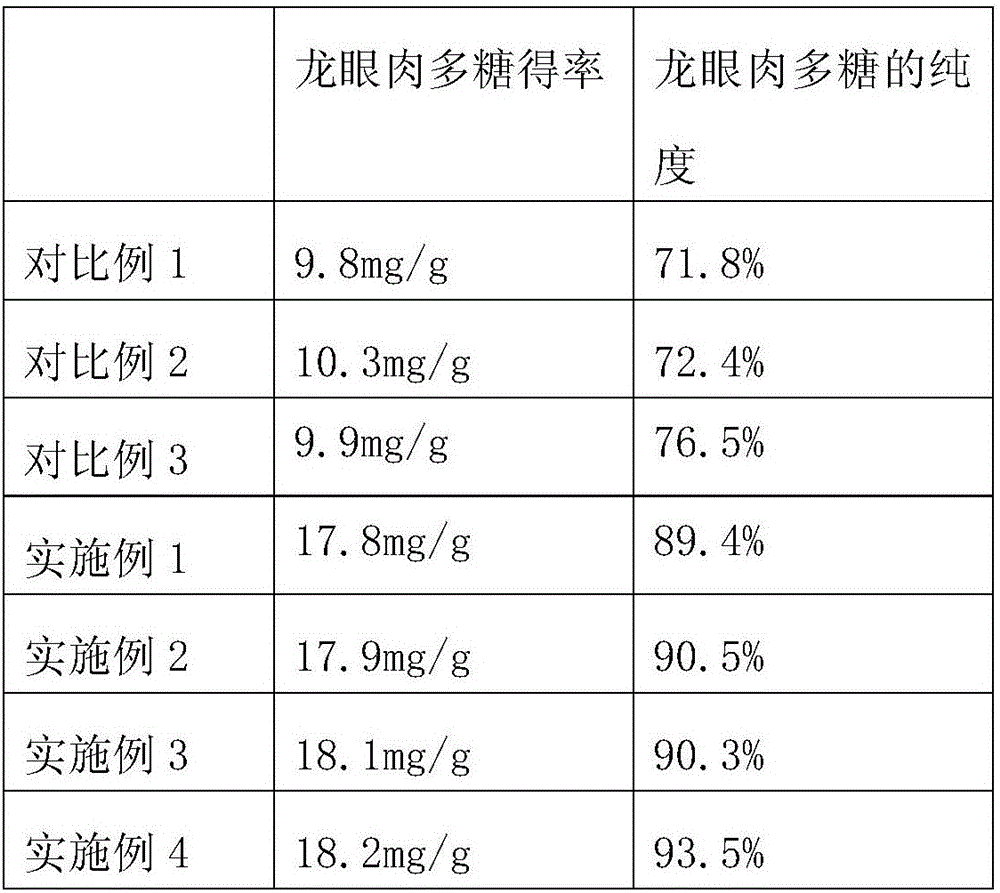

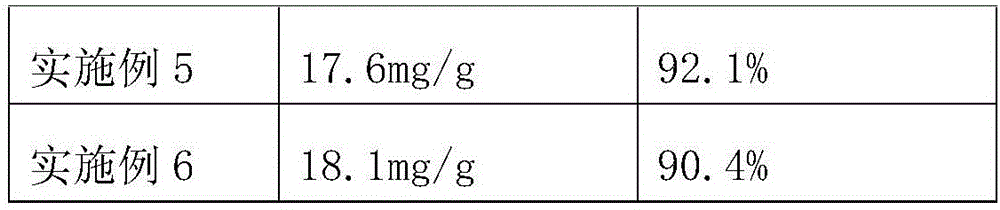

A technology of longan meat polysaccharide and longan meat is applied in the field of deep processing of longan, which can solve the problems of high cost, low efficiency and long time, and achieve the effects of improving yield, improving enzymatic hydrolysis efficiency and improving enzymatic hydrolysis speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] 1. Preliminary preparation:

[0035] Preparation of copper oxide-zirconia catalyst: add 35g of anhydrous copper sulfate and 30g of zirconium oxychloride to 200g of deionized water, add 40% mass fraction of sodium hydroxide solution dropwise while stirring, and adjust the pH to 9. Filter, take the filter residue, wash twice with deionized water, air dry, microwave dry for 10 minutes, and finally roast in a muffle furnace at 1100°C for 2 hours to obtain a copper oxide-zirconia catalyst.

[0036] Preparation of lye: mix 10 g of potassium hydroxide, 10 g of 25% ammonia water and 100 g of deionized water, and stir to obtain lye.

[0037] Preparation of the ternary complex enzyme: mix 50 g of acid cellulase, 20 g of fructosidase and 15 g of protease to obtain a ternary complex enzyme.

[0038] The preparation of mixed alcohol solution: mix 1000 g of 95% mass fraction of ethanol aqueous solution, 100 g of 70% mass fraction of n-propanol aqueous solution, and 100 g of 70% mass fraction...

Embodiment 2

[0046] 1. Preliminary preparation:

[0047] Preparation of copper oxide-zirconia catalyst: Add 38g of anhydrous copper sulfate and 35g of zirconium oxychloride to 240g of deionized water, add 45% sodium hydroxide solution dropwise while stirring, and adjust the pH to 10. Filter, take the filter residue, wash 3 times with deionized water, air dry, microwave dry for 13 min, and finally roast in a muffle furnace at 1200° C. for 2.5 h to obtain a copper oxide-zirconia catalyst.

[0048] Preparation of lye: mix 10 g of potassium hydroxide, 18 g of 25% ammonia water and 120 g of deionized water, and stir to obtain lye.

[0049] Preparation of ternary complex enzyme: 65g acid cellulase, 23g fructosidase and 20g protease are mixed uniformly to obtain a ternary complex enzyme.

[0050] Preparation of mixed alcohol solution: mix 1200 g of 95% mass fraction of ethanol aqueous solution, 100 g of 75% mass fraction of n-propanol aqueous solution, and 133 g of 78% mass fraction of isopropanol aqueou...

Embodiment 3

[0058] 1. Preliminary preparation:

[0059] Preparation of copper oxide-zirconia catalyst: Add 43g of anhydrous copper sulfate and 37g of zirconium oxychloride to 260g of deionized water, add dropwise 44% sodium hydroxide solution while stirring, and adjust the pH to 11. Filter, take the filter residue, wash 3 times with deionized water, air dry, microwave dry for 15 minutes, and finally roast in a muffle furnace at 1150°C for 3 hours to obtain a copper oxide-zirconia catalyst.

[0060] Preparation of lye: mix 10g of potassium hydroxide, 24g of 25% ammonia water and 130g of deionized water, stir evenly to obtain lye.

[0061] Preparation of ternary complex enzyme: 66g acid cellulase, 30g fructosidase and 26g protease are mixed uniformly to obtain a ternary complex enzyme.

[0062] The preparation of mixed alcohol solution: mix 1450 g of 95% mass fraction of ethanol aqueous solution, 100 g of 75% mass fraction of n-propanol aqueous solution, and 170 g of 82% mass fraction of isopropano...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com