Potential impurity compound of Nintedanib, as well as preparation method, application and detection method of potential impurity compound

A technology of nintedanib and compounds, which is applied in the field of potential impurity compounds of nintedanib, can solve the problems of public reporting of no impurities, and achieve the effect of improving quality standards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

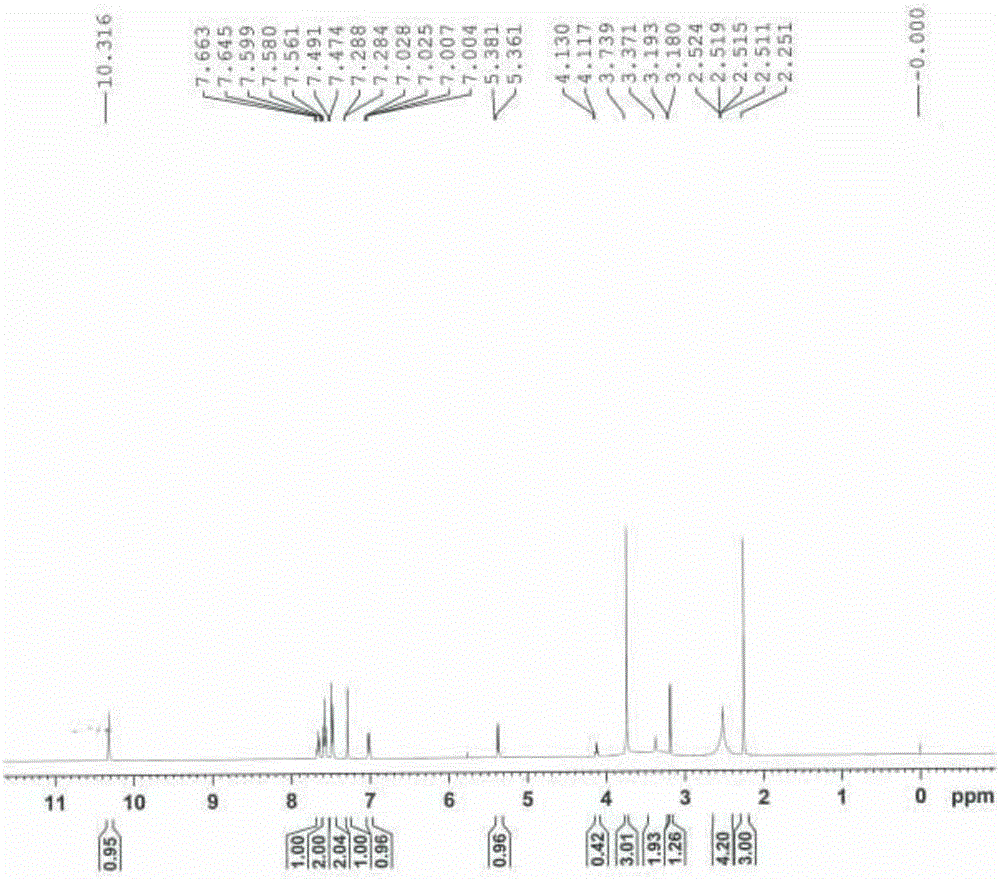

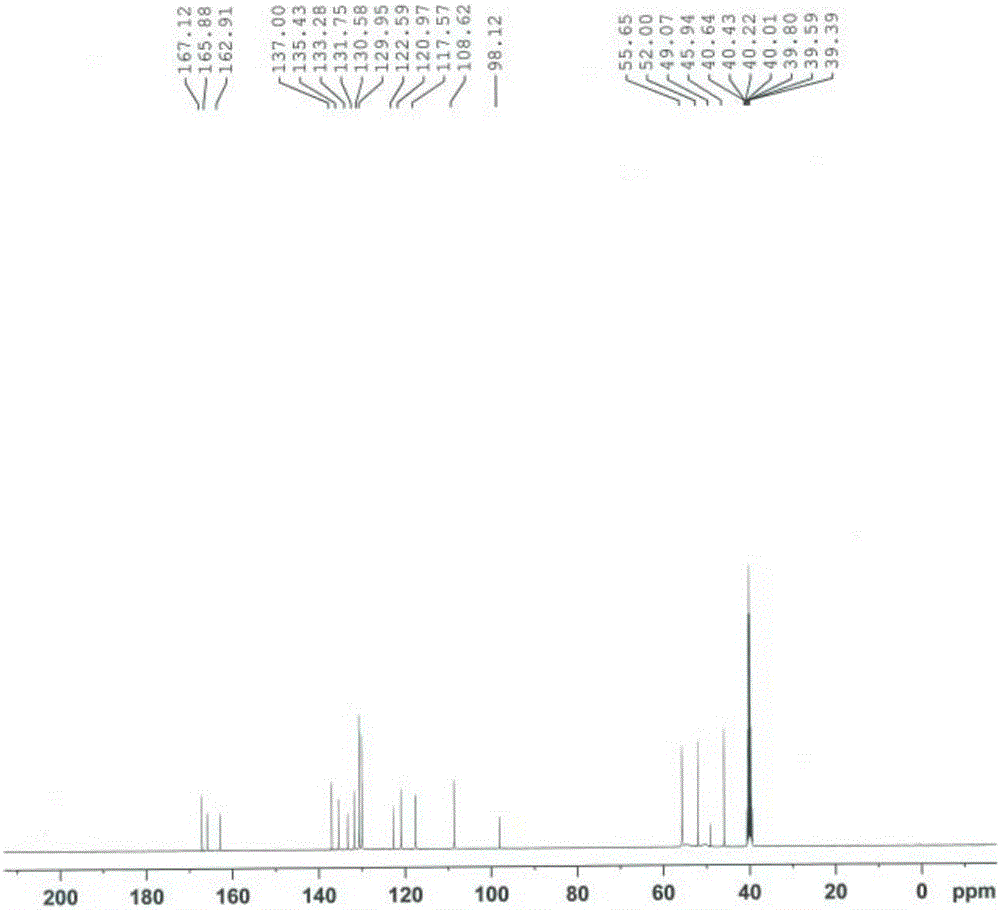

[0056] 3-[methoxy(phenyl)methylene]-2-oxoindoline-6-carboxylic acid methyl ester (8.8g, 28mol) and N-methylpiperazine (5.6g, 57mmol) Add 80mL of methanol, stir and react at 60°C, the reaction is completed in 2-5 hours, the reaction solution is cooled, and a solid precipitates, the solid is filtered, rinsed with methanol, and 8.9g of impurity compound is obtained as a light red solid.

[0057] HPLC detection, product purity 96.2%.

[0058] The HPLC method is: take 5 mg of the impurity compound, add it to a 25 mL volumetric flask, and use an appropriate amount of mobile phase A-mobile phase B (45:55) to dissolve and dilute to the mark with an appropriate amount of ultrasound, as the test solution.

[0059] The chromatographic conditions are:

[0060] (1) Chromatographic column: octadecylsilane bonded silica gel.

[0061](2) Mobile phase: mobile phase A is 20mmol / L potassium dihydrogen phosphate solution (adjust pH value to 3.0 with phosphoric acid), mobile phase B is acetonitr...

Embodiment 2

[0066] Methyl N-acetyl-3-[methoxy(phenyl)methylene]-2-oxoindoline-6-carboxylate (10 g, 28 mmol) and N-methylpiperazine (5.6 g, 57mmol) was added into 50mL of methanol and 5mL of N,N-dimethylformamide, reflux reaction at 68°C, after 2-4 hours of reaction, piperidine (4.8g, 57mmol) was added, and the reaction was continued for 2 hours. The reaction solution was cooled, and the temperature was lowered to precipitate a solid, which was filtered, and the residue was slurried with 30 mL of methanol, and filtered to obtain 5.7 g of impurity compound as a light red solid. As detected by HPLC, the purity of the impurity compound was 97.4%.

Embodiment 3

[0068] Methyl N-chloroacetyl-3-[methoxy(phenyl)methylene]-2-oxoindoline-6-carboxylate (10 g, 28 mmol) and N-methylpiperazine ( 5.6 g, 57 mmol) was added into 30 mL of N,N-dimethylformamide, and reacted at 80° C. After 2 hours of reaction, piperidine (4.8 g, 57 mmol) was added, and the reaction was continued for 2 hours. The reaction solution was cooled, added with 100 mL of water, extracted with 100 mL of dichloromethane, and washed with 50 mL of saturated sodium chloride solution x 3. The organic phase was dried over anhydrous sodium sulfate, filtered, and dichloromethane was distilled off from the filtrate under reduced pressure. The residue was crystallized by adding 50 mL of isopropanol, and filtered to obtain 7.4 g of impurity compound as a light red solid. HPLC detection showed that the purity of the impurity compound was 98.5%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com