Artificial marble having decorative effect and manufacturing method thereof

An artificial marble and decorative effect technology, applied in the field of building decoration materials, can solve the problems of not considering the influence of shrinkage and dimensional deformation of cement, insufficient texture details, and long maintenance cycle of finished products, so as to reduce production and operation costs and shorten maintenance time. , the effect of improving labor productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

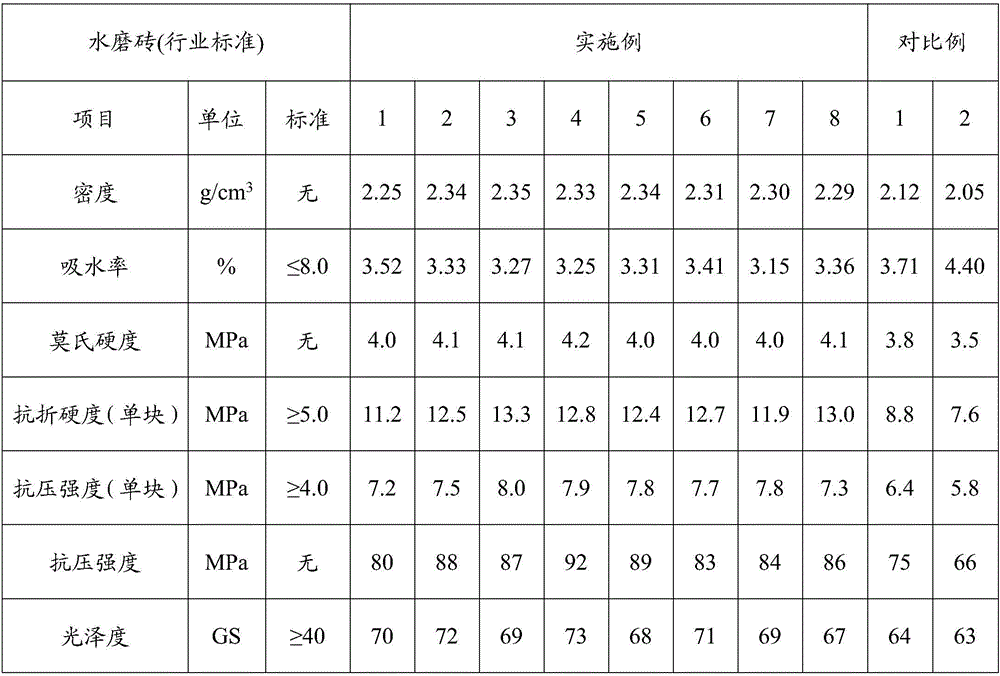

Examples

Embodiment 1

[0067] An artificial marble slab with a decorative effect, comprising the following components:

[0068] Sulphoaluminate cement, white quartz sand, water-based polycarboxylate superplasticizer, water-based silicone defoamer, pigment, concrete anti-shrinkage agent.

[0069] As described in this embodiment, an artificial marble plate with a decorative effect comprises the following components in parts by weight:

[0070] 25 parts of sulphoaluminate cement, 65 parts of 80-120 mesh white quartz sand, 10 parts of potassium feldspar powder, 0.5 parts of water-based polycarboxylate superplasticizer, 1 part of water-based silicone defoamer, 1 part of pigment, concrete anti-shrinkage 0.25 parts of the agent.

[0071] As described in this embodiment, it also includes the first base layer, including the following components: 25 parts of sulphoaluminate cement, 45 parts of 40-70 mesh white quartz sand, 15 parts of 70-120 mesh white quartz sand, quartz stone fragments Or 15 parts of conc...

Embodiment 2

[0090] This embodiment is improved on the basis of Embodiment 1, and the content described in Embodiment 1 is also included in this embodiment, and will not be described in detail here.

[0091] Described in this embodiment, in parts by weight, includes the following components:

[0092] 26 parts of sulphoaluminate cement, 64 parts of 80-120 mesh white quartz sand, 10 parts of potassium feldspar powder, 0.5 parts of water-based polycarboxylate superplasticizer, 2 parts of water-based silicone defoamer, 0.8 parts of pigment, anti-shrinkage of concrete 0.25 part of dose;

[0093] Described in this embodiment, in parts by weight, also includes the following components:

[0094] 26 parts of sulfoaluminate cement, 40 parts of 40-70 mesh white quartz sand, 16 parts of 70-120 mesh white quartz sand, 13 parts of quartz stone fragments or concrete slag, 0.7 part of chopped glass fiber, water-based polycarboxylic acid water-reducing 0.5 parts of agent, 1.6 parts of water-based silicon...

Embodiment 3

[0098] This embodiment is improved on the basis of Embodiment 1, and the content described in Embodiment 1 is also included in this embodiment, and will not be described in detail here.

[0099] Described in this embodiment, in parts by weight, includes the following components:

[0100] 27 parts of sulfoaluminate cement, 63 parts of 80-120 mesh white quartz sand, 8 parts of potassium feldspar powder, 1 part of water-based polycarboxylate superplasticizer, 2 parts of water-based silicone defoamer, 1.2 parts of pigment, anti-shrinkage of concrete 0.3 part of agent;

[0101] Described in this embodiment, in parts by weight, also includes the following components:

[0102] 27 parts of sulphoaluminate cement, 43 parts of 40-70 mesh white quartz sand, 15 parts of 70-120 mesh white quartz sand, 12 parts of quartz stone fragments or concrete slag, 1.2 parts of chopped glass fiber, water-based polycarboxylic acid water-reducing 1.2 parts of agent, 2 parts of water-based silicone def...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com