Integrated treatment method for high-salinity and high-concentration refractory organic wastewater resulted from cellulose ether production

A treatment method and technology for organic wastewater, applied in biological water/sewage treatment, multi-stage water treatment, water/sewage treatment, etc., can solve problems such as difficult treatment of organic wastewater, and achieve the effect of reducing foam and improving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

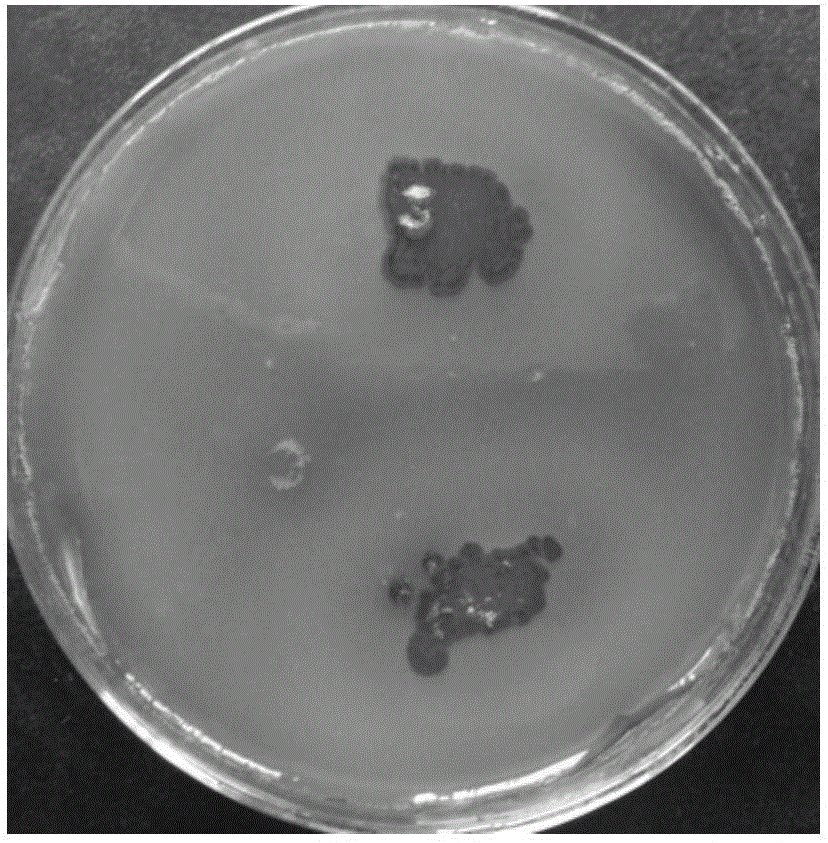

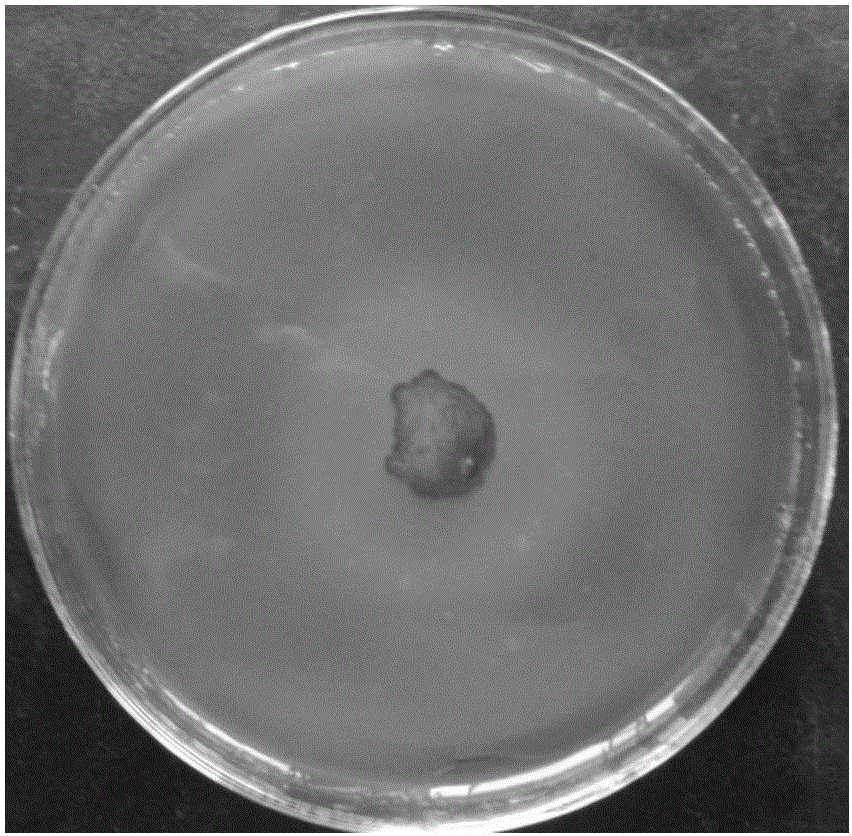

Image

Examples

Embodiment 1

[0043] The comprehensive waste water COD of the production of methyl cellulose ether and hydroxypropyl methyl cellulose ether is 7000-8000mg / L, NH 4 -N 20~25mg / L, salt content 35~40g / L, after pretreatment of 10L of wastewater in the laboratory each time, four 3L devices are used in series, and the treatment conditions of the biochemical small test are as follows.

[0044] (1) Adjust the pH to 6.0 in the organic wastewater producing methyl cellulose ether and hydroxypropyl methyl cellulose ether, add PAC to a final concentration of 100 mg / L, stir at 300 rpm for 5 minutes, then add PAM to the final concentration Concentration 1mg / L, 100 rpm / min stirring for 5 minutes. Take the supernatant from the static sediment.

[0045] (2) Take the supernatant from the wastewater treated in step (1) to carry out Fenton reaction pretreatment, add 0.8% FeSO 4 (W / V) After stirring and dissolving, use 10% H 2 SO 4 (V / V) adjust pH to 3.0, add 1.6% H 2 o 2 (V / V),H 2 o 2 Add in several time...

Embodiment 2

[0057] An enterprise mainly produces methyl cellulose ether and hydroxypropyl methyl cellulose ether, the comprehensive wastewater volume is 500t / d, COD is 7000-8000mg / L, NH 4 ~N 20-25mg / L, salt content 35~40g / L, the total amount of wastewater discharge from the enterprise has been controlled and cannot be diluted to reduce the salt content for biochemical treatment, and the cost of 500t / d water through three-effect evaporation is too high. Using this integrated technology for wastewater treatment can Meet the emission standards of nanotubes.

[0058](1) Adjust the pH to 6.0 in the organic wastewater producing methyl cellulose ether and hydroxypropyl methyl cellulose ether, add PAC to a final concentration of 100 mg / L, stir at 300 rpm for 5 minutes, then add PAM to the final concentration Concentration 1mg / L, 100 rpm / min stirring for 5 minutes. Take the supernatant from the static sediment.

[0059] (2) Take the supernatant from the wastewater treated in step (1) to carry ou...

Embodiment 3

[0071] An enterprise mainly produces methyl cellulose ether and hydroxypropyl methyl cellulose ether. The high-concentration wastewater volume is about 60-70t / d, the COD is 12000-15000mg / L, and the salt content is 10-15g / L. Due to the high COD of wastewater, The refractory substance cellulose ether contained in the wastewater is also high, about 3.3g / L, so that the treatment becomes more difficult.

[0072] (1) Considering that the amount of high-concentration wastewater is small, the method of low-temperature vacuum distillation and desolventization is adopted. Firstly, the waste water is desolvated by vacuum at 50°C to recycle the solvent. After desolventization, the removal rate of COD is about 30%, and COD can be reduced. To 8000-10000mg / L. The waste water is then treated using an integrated treatment process.

[0073] (2) Adjust the pH of the high-salt organic wastewater produced in cellulose ether to 6.0, add PAC to a final concentration of 100 mg / L, stir at 300 rpm for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com