Hydrothermal method preparation technology for BiVO4 nanowires

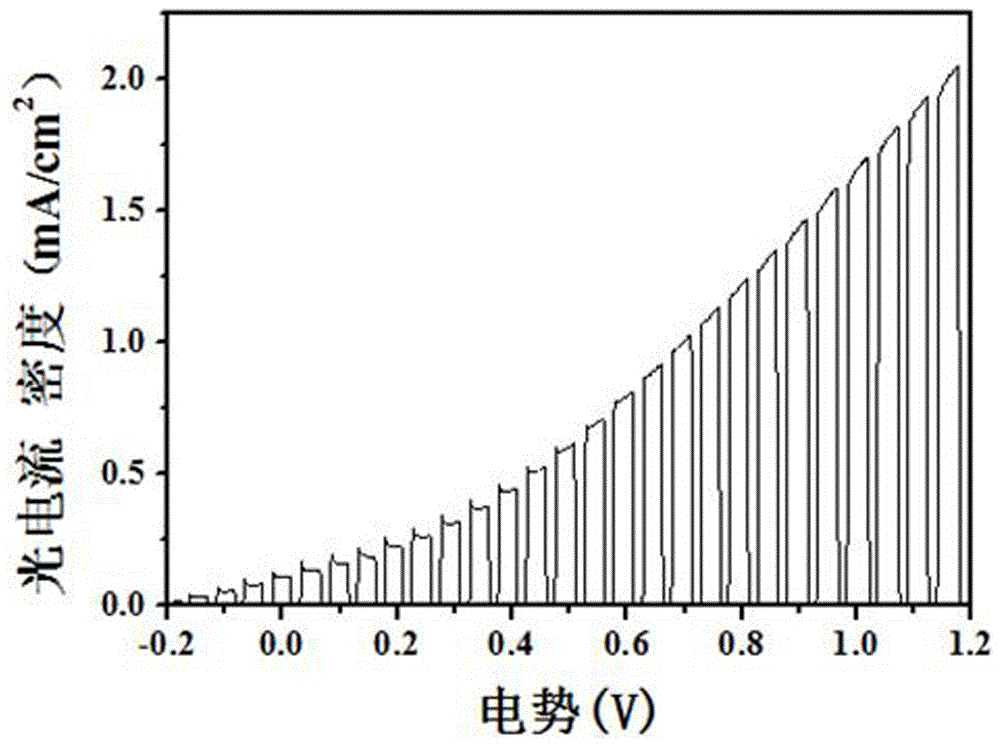

A technology of preparation process and hydrothermal method, applied in the direction of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of high cost, cumbersome process, complicated preparation equipment, etc., and achieve good shape characteristics , high photocatalytic activity and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] BiVO 4 The hydrothermal preparation process of nanowires is as follows:

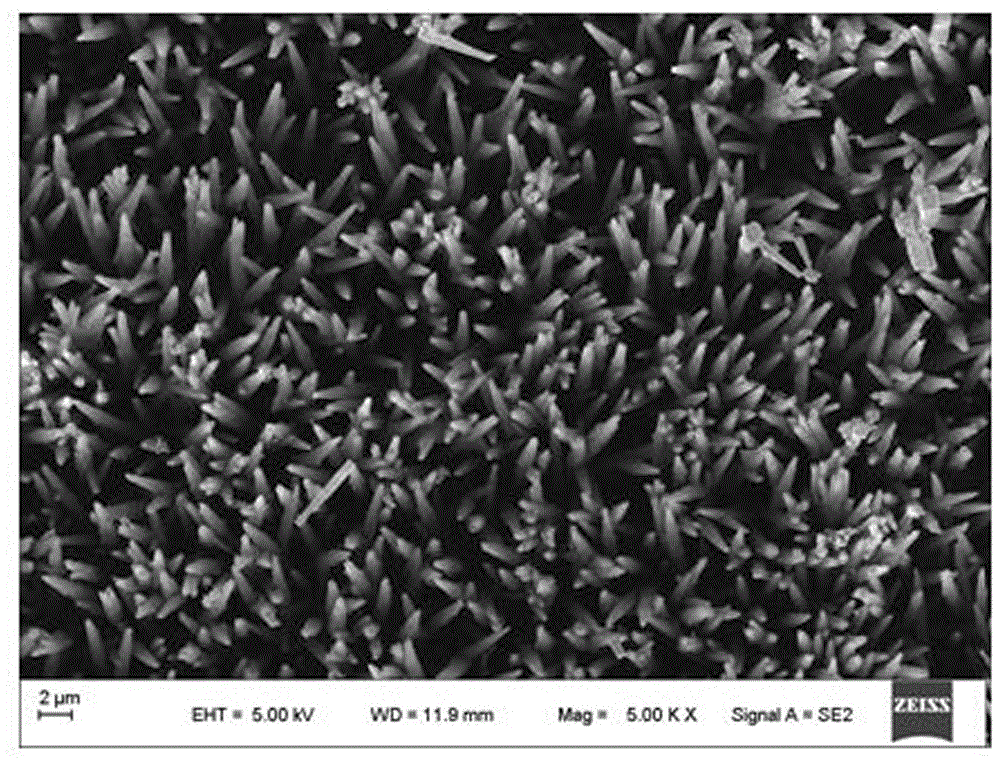

[0023] Weigh 5 mmol of bismuth nitrate, 5 mmol of ammonium metavanadate and 10 mmol of citric acid and dissolve in 15 mL of 23.3% HNO 3 solution to form A solution; take 8mL A solution in a 50mL glass beaker, add 0.48g PVA and 2mL acetic acid, stir until completely dissolved, and obtain viscous BiVO 4 blue seed solution; step BiVO 4 The seed solution was spin-coated on clean FTO glass, placed in a muffle furnace, heated to 400 °C at a rate of 2 °C / min, and calcined for 5 h to obtain BiVO 4 Seed layer, placed in the Teflon liner of the reactor; in a 50mL glass beaker, add 16mL deionized water and 4mL HNO 3 , stir to make it evenly mixed, then add 1mmol of ammonium metavanadate and 1mmol of bismuth nitrate, after it is completely dissolved, add 5.7g of NaHCO 3 , after stirring for 30 minutes, transferred to the polytetrafluoroethylene lining of the above reaction kettle, reacted at 120 °C for 6 ...

Embodiment 2

[0027] BiVO 4 The hydrothermal preparation process of nanowires is as follows:

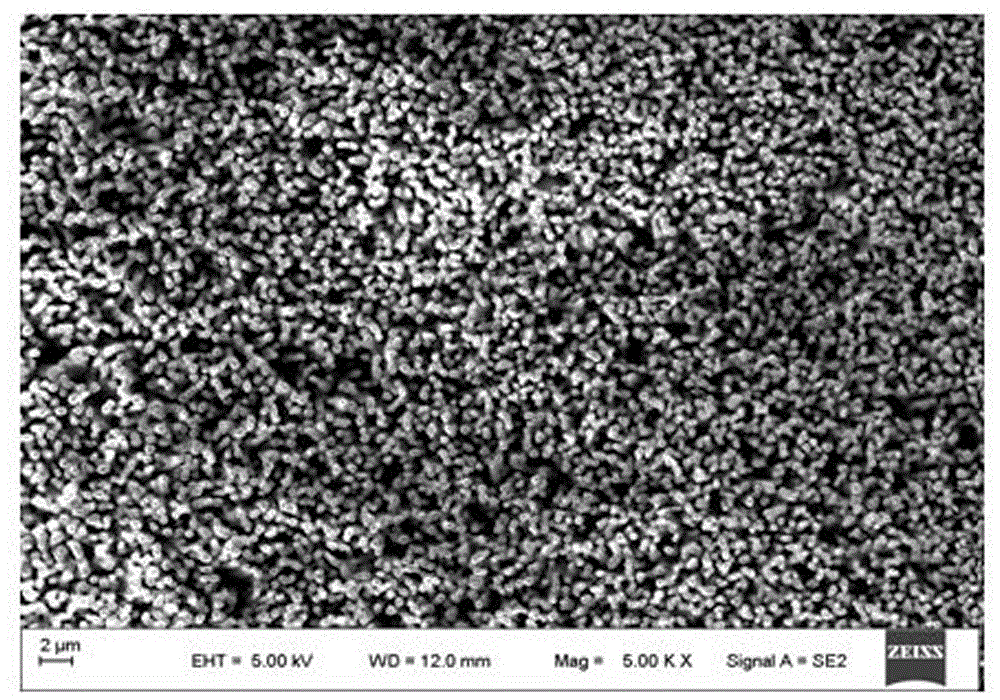

[0028] Weigh 3mmol of bismuth nitrate, 3mmol of ammonium metavanadate and 8mmol of citric acid dissolved in 18mL of 23.3% HNO 3 solution to form A solution; take 6mL A solution in a 50mL glass beaker, add 0.52g PVA and 1.5mL acetic acid, stir until completely dissolved, and obtain viscous BiVO4 Blue seed solution; the step BiVO was spin-coated 4 The seed solution was spin-coated on clean FTO glass, placed in a muffle furnace, heated to 400 °C at a rate of 2 °C / min, and calcined for 4 h to obtain BiVO 4 Seed layer, placed in the polytetrafluoroethylene liner of the reactor; in a 50mL glass beaker, add 18mL deionized water and 5mL HNO 3 , stir to make it evenly mixed, then add 0.5mmol of ammonium metavanadate and 0.5mmol of bismuth nitrate, and add 5.0g of NaHCO after it is completely dissolved 3 , after stirring for 20 min, transferred to the polytetrafluoroethylene lining of the above reaction ...

Embodiment 3

[0030] BiVO 4 The hydrothermal preparation process of nanowires is as follows:

[0031] Weigh 4mmol of bismuth nitrate, 4mmol of ammonium metavanadate and 9mmol of citric acid and dissolve them in 20mL of 23.3% HNO 3 solution to form A solution; take 7mL A solution in a 50mL glass beaker, add 0.64g PVA and 1.8mL acetic acid, stir until completely dissolved, and obtain viscous BiVO 4 Blue seed solution; the step BiVO was spin-coated 4 The seed solution was spin-coated on clean FTO glass, placed in a muffle furnace, heated to 400 °C at a rate of 2 °C / min, and calcined for 6 h to obtain BiVO 4 Seed layer, placed in the polytetrafluoroethylene liner of the reaction kettle; in a 50mL glass beaker, add 20mL deionized water and 6mL HNO 3 , stir to make it evenly mixed, then add 0.8mmol of ammonium metavanadate and 0.7mmol of bismuth nitrate, and add 5.3g of NaHCO after it is completely dissolved 3 , after stirring for 25min, transferred to the polytetrafluoroethylene lining of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com