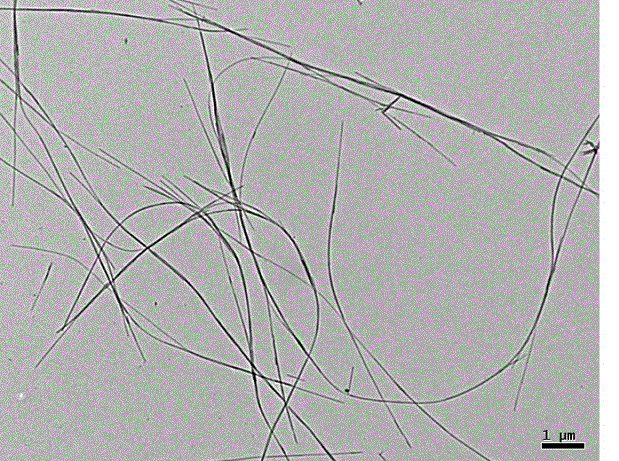

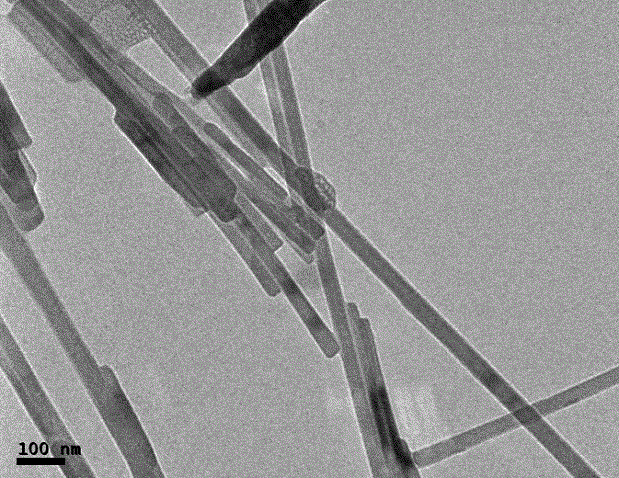

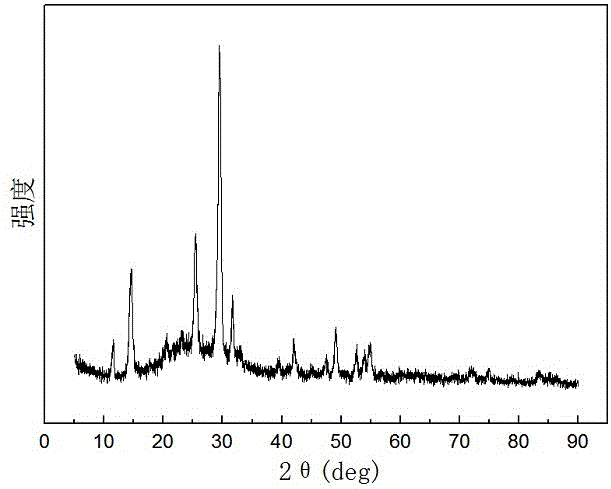

Method for preparing high-length-diameter-ratio calcium sulfate nanowires under low-temperature conditions

A technology with high aspect ratio and low temperature conditions, applied in the direction of nanotechnology, calcium/strontium/barium sulfate, etc., can solve the problems of complex preparation process, high reaction temperature, and high equipment requirements, and achieve simple preparation process and low reaction temperature , good solubilizing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0021] A method for preparing calcium sulfate nanowires with high aspect ratio under low temperature conditions, the specific steps are;

[0022] (1). Preparation of sodium sulfate reverse microemulsion composed of n-pentanol, cyclohexane, sodium sulfate, cetyltrimethylammonium bromide, the steps are: 3.2ml of n-pentanol solution, cyclohexane 38ml of alkane solution and 1ml of sodium sulfate solution with a molar concentration of 0.1mol / L were mixed evenly, then 2.1g of cetyltrimethylammonium bromide was added to the mixed solution, and after completely dissolving, a sodium sulfate reverse microemulsion was prepared ;

[0023] (2). Preparation of calcium chloride reverse microemulsion composed of n-amyl alcohol, cyclohexane, sodium sulfate, cetyltrimethylammonium bromide, the steps are: 3.2ml n-amyl alcohol solution, volume Mix 38ml of cyclohexane solution with a fraction of 92.2vol.% and 1ml of calcium chloride solution with a molar concentration of 0.1mol / L, and then add 2....

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com