A high-efficiency preparation method of mesoporous silica particles with high-efficiency blood coagulation function

A technology of mesoporous silica and coagulation function, applied in the field of medical biomaterials, can solve the problems of high production cost, high price, increased cost, etc., and achieve the effects of eliminating polluting dust, shortening the preparation period and reducing the production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] The specific preparation process includes the preparation of wet gel and particle forming and drying steps.

[0034] Gel preparation: Dissolve ethyl orthosilicate in 1-10% hydrochloric acid / ammonia aqueous solution, the pH value of the system is 1-12, control the temperature at 30-60°C, stir at 100-200 rpm for 2-15 hours, The solution is gelled and then gelled to form a gel, and the gel is baked in an oven at 50-80° C. for 2-10 hours, and the water holding capacity of the gel is controlled at 200-800%.

[0035] Granule forming: Determine the amount of forming agent according to the water holding capacity of the wet gel, add the wet gel and forming agent to the granulator; control the stirring speed at 500-3000 rpm, and the wet soft material after stirring is formed into strips, The cutting and spheronizing process obtains the silica pellets.

[0036] Drying: Calcining the wet pellets in a muffle furnace / drying in an oven / lyophilizing in a freeze dryer to obtain mesopor...

Embodiment 1

[0050]Prepare 280mL of 3% hydrochloric acid aqueous solution, stir until clear, the pH value is 2-4, add 18.37mL tetraethyl orthosilicate TEOS dropwise, stir at 60°C and 200 rpm for 2h, add 30mL ammonia water after the reaction and continue stirring After 1 min, the sample was collected by filtration to obtain the initial wet gel; the initial wet gel was heated in an oven at 50° C. for 1 hour, so that the water content of the wet gel was about 400%.

[0051] Add the wet gel and cellulose acetate (according to the weight ratio: gel (dry) / forming agent=10:4) into the granulator, stir at 2000 rpm for 30 minutes, adjust and control the bar pulping at 800 rpm and cut The rotational speed of the particle knife is 3000 rpm to obtain wet silicon dioxide particles; the wet silicon dioxide particles are calcined at 600° C. for 3 hours to obtain silicon dioxide particles.

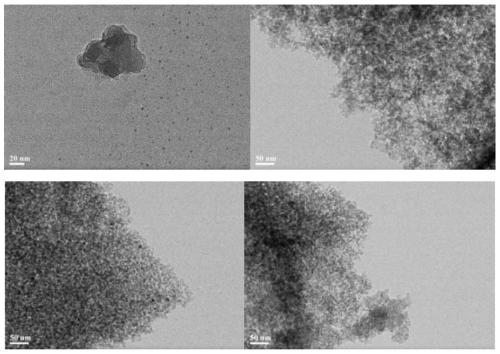

[0052] SEM images of silica particles figure 1 As shown, the pore size ranges from 6-9nm, which are mesoporous sil...

Embodiment 2

[0054] Prepare 250mL of 5% aqueous ammonia solution, the pH value is 10-12, add 16mL TEOS dropwise, stir at 30°C and 150 rpm for 3h, add 50mL hydrochloric acid and continue stirring for 2min after the reaction, collect the sample by filtration, and obtain the initial wet condensation Gel; heat the initial wet gel in a microwave oven for 20 minutes to obtain a wet gel with a water content of about 600%.

[0055] Add the wet gel and diatomaceous earth (according to the weight ratio: gel (dry) / diatomite=10:6) into the granulator, stir at 1000 rpm for 60 minutes, adjust and control the bar making at 500 rpm and The dicing knife was set at 1500 rpm to obtain wet silica granules; the wet silica granules were baked in an oven at 60° C. for 3 hours to obtain silica granules.

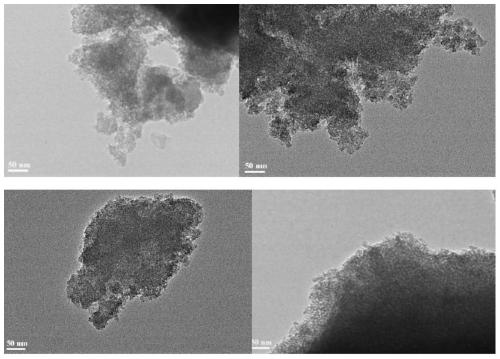

[0056] After testing, the pore diameter ranges from 8-11nm, which is mesoporous silica particles.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com