Biological carbon electrode material and preparation method thereof

An electrode material, bio-carbon technology, applied in carbon preparation/purification, battery electrodes, circuits, etc., can solve problems such as low utilization rate, achieve the effect of low cost, less purity, and ensure cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] In the present invention, rapeseed stalks, corn stalks, rice husks, rapeseed husks, wheat straws or cotton stalks are used as plant stalks; the treatment methods are the same, and the rapeseed husks are used as an example to illustrate the present invention. The preparation method comprises the following steps:

[0032] First, mix every 3g of washed, dried and shredded rapeseed shells with 20-50mL of water; ball mill for 1-2h at a rotating speed of 300-500r / min, and after drying, the mass ratio of the activator to the crushed rapeseed shells is ( 0.5~3): 1 add activator, the activator can be KOH, NaOH, ZnCl 2 , K 2 CO 3 , any one of MgO; transferred to the atmosphere furnace, under the protection of the atmosphere, the temperature is raised to the set temperature at a heating rate of 1-10°C / min, such as 500-1100°C for 2-6h; the protective gas is nitrogen, Any one of argon, helium, neon or a mixed gas of two or more, the gas flow rate is 20sccm~100sccm; then add it to...

Embodiment 1

[0034] Mix 3g of washed, dried and shredded rape shells with 20ml of water; ball mill for 2h at a rotating speed of 300r / min, mix KOH and rape shells in a ratio of 1 after drying, transfer to an atmosphere furnace, and heat in an argon atmosphere (50sccm) Under protection, the temperature was raised to 800°C for 2 hours; then magnetically stirred with 3mol / L hydrochloric acid at room temperature for 12 hours; finally, washed with deionized water and ethanol for 3 times, and vacuum-dried for 12 hours to obtain a network structure biocarbon electrode material.

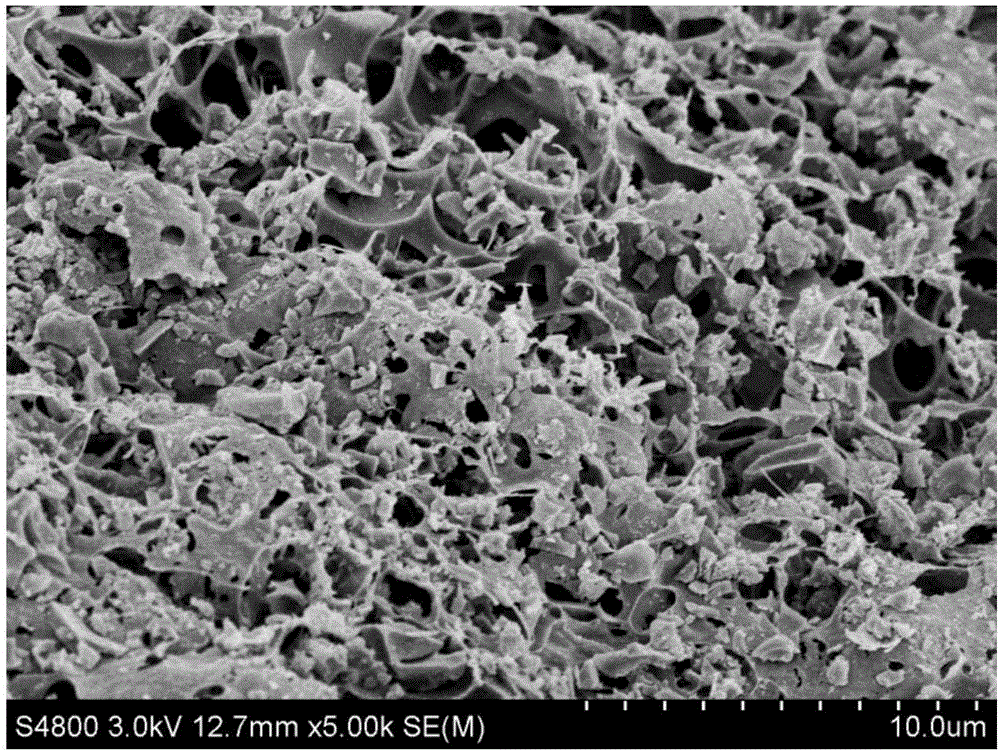

[0035] From figure 1 It can be seen that the prepared carbon material has a three-dimensional network structure;

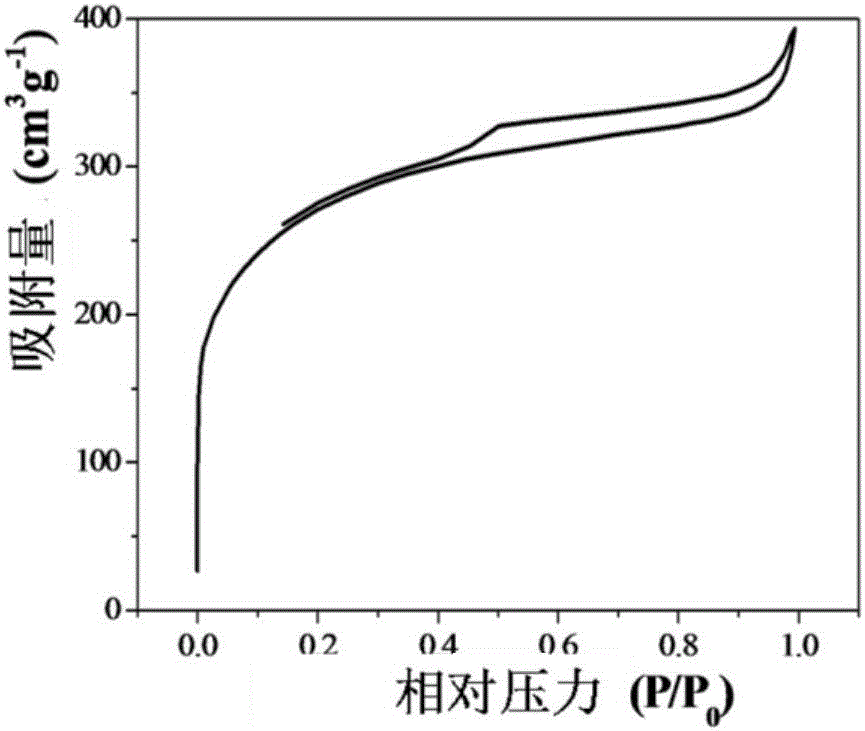

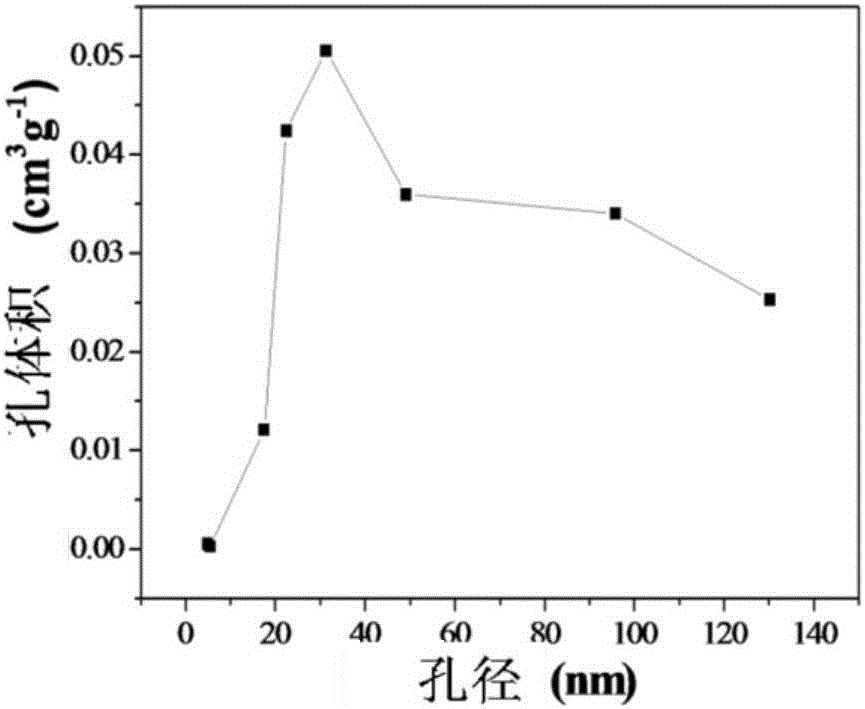

[0036] It can be seen from Figure 2(a) that the prepared carbon material has a large specific surface area of 673.5m 2 g -1 ; As can be seen from Figure 2 (b), the pore size distribution is at 30-50nm;

[0037] The sodium ion battery assembled with the carbon electrode material has excellent electrochem...

Embodiment 2

[0039] Mix 3g of washed, dried and shredded rapeseed shells with 30ml of water; ball mill for 2h at a rotating speed of 500r / min, mix the dried KOH and rapeseed shells in a ratio of 3, transfer them to an atmosphere furnace, and heat them in a neon gas atmosphere (100sccm) Under protection, the temperature was raised to 1000°C for 2 hours; then magnetically stirred with 3mol / L hydrochloric acid at room temperature for 12 hours; finally, washed with deionized water and ethanol for 3 times, and vacuum-dried for 24 hours to obtain a network structure biocarbon electrode material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com