Prestressed pipe pile transport vehicle with loading and unloading functions

A technology for prestressed pipe piles and transport vehicles, which is applied to goods transport vehicles, arrangement of loading and unloading vehicles, transporting objects, etc., can solve the problems of wasting a lot of time, increasing the cost of loading and unloading pipe piles, and increasing the cost of loading and unloading.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

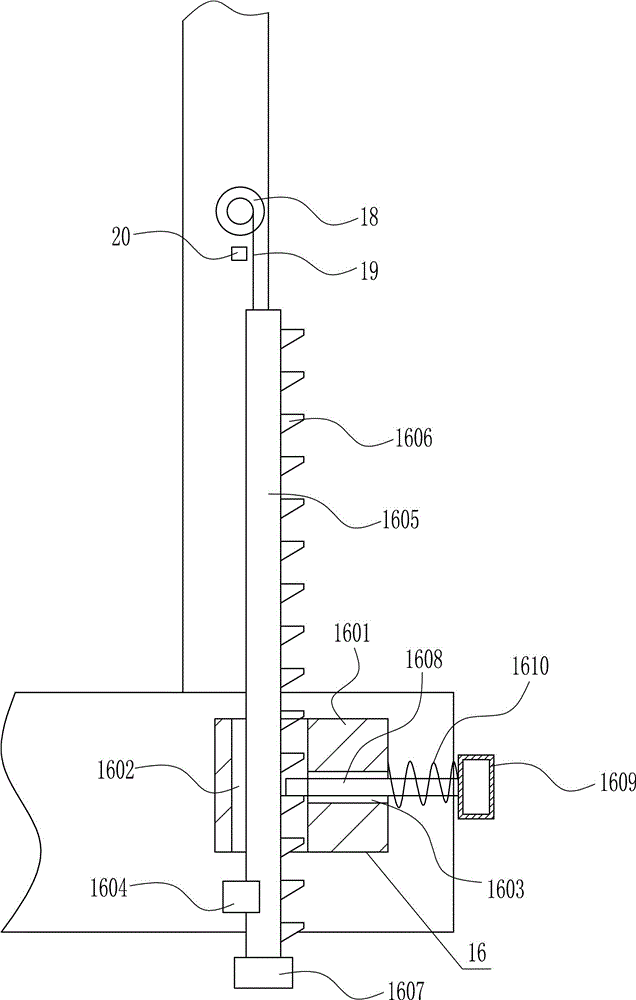

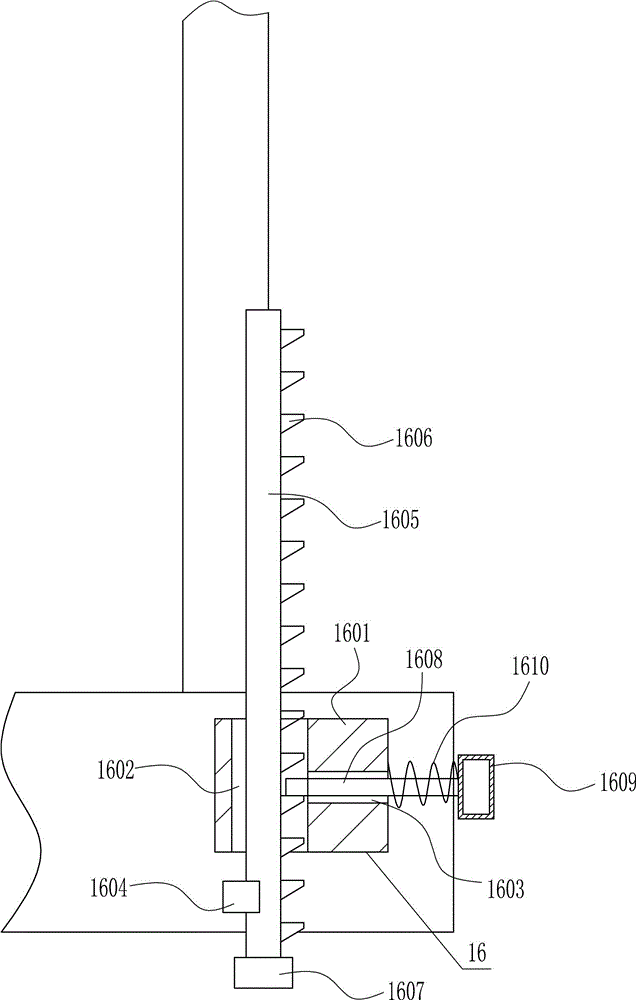

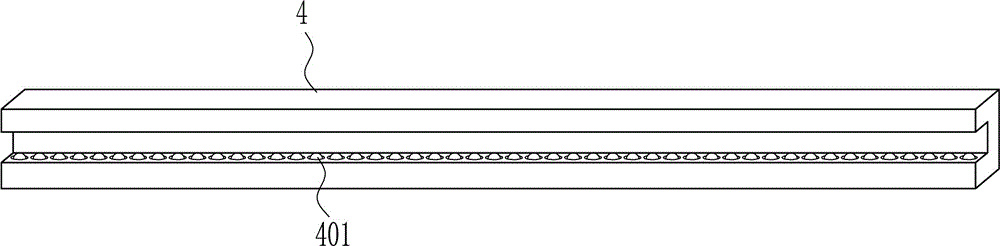

[0042] A prestressed pipe pile transport vehicle with loading and unloading functions, such as Figure 1-9 As shown, it includes a car body 1, a car plate 2, an N-shaped frame 3, a guide rail 4, a ball 401, a driving mechanism 5, a moving beam 6, a rack 7, an inverted T-shaped plate 8, a wire hole 9, and a lifting mechanism 10 and clamping device 11, car body 1 rear portion is provided with car plate 2, and car plate 2 tops are installed with a plurality of N-shaped frames 3 by the mode of bolt connection, and the middle of N-shaped frame 3 inner side tops is connected with two by bolts. A guide rail 4, two guide rails 4 are symmetrically arranged front and back, and there is a gap between the two guide rails 4, balls 401 are provided on the inner top and bottom of the guide rail 4, and a driving mechanism 5 is installed between the right top of the two guide rails 4 , there is a moving beam 6 between the inner sides of the two guide rails 4, the moving beam 6 is slidingly mat...

Embodiment 2

[0051] A prestressed pipe pile transport vehicle with loading and unloading functions, such as Figure 1-13As shown, it includes a car body 1, a car plate 2, an N-shaped frame 3, a guide rail 4, a ball 401, a driving mechanism 5, a moving beam 6, a rack 7, an inverted T-shaped plate 8, a wire hole 9, and a lifting mechanism 10 and clamping device 11, car body 1 rear portion is provided with car plate 2, and car plate 2 tops are installed with a plurality of N-shaped frames 3 by the mode of bolt connection, and the middle of N-shaped frame 3 inner side tops is connected with two by bolts. A guide rail 4, two guide rails 4 are symmetrically arranged front and back, and there is a gap between the two guide rails 4, balls 401 are provided on the inner top and bottom of the guide rail 4, and a driving mechanism 5 is installed between the right top of the two guide rails 4 , there is a moving beam 6 between the inner sides of the two guide rails 4, the moving beam 6 is slidingly mat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com