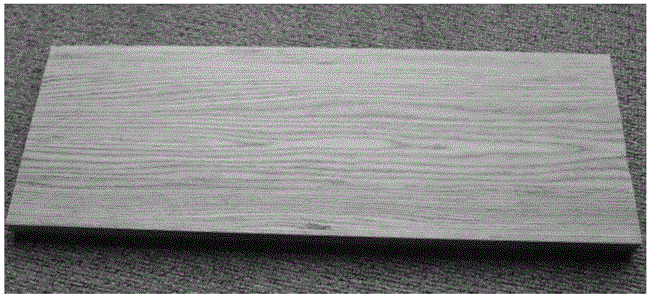

Heavy wood material formed by pressing wood veneers and preparation method thereof

A wood veneer and board technology, which is used in the joining of wood veneers, veneer presses, plywood presses, etc., can solve problems such as cost reduction, and achieve rich wood grain features, low manufacturing costs, and great decoration. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Take poplar veneer with a moisture content of 15-20% (the veneer size is 1270*650*4.0mm, no dead knots), and use a roller with a rhombic cone to split the veneer on both sides to make dense holes. , The hole spacing is less than 3.0 mm, relatively uniform, and the single-sided depth is 2 mm. It is immersed in the phenolic resin glue while mechanically splitting, and soaked for about 5 minutes. The raw material after dipping is quantitatively (quantified according to the required density, according to the density of 1.2 in this example), transported into the mold cavity of the molding machine, first press the predetermined shape, and then gradually pressurize to 55Mpa, when the pressure is finally reached to the design value , The material is dense and uniform. Clamp the mold, fix the material in the mold, send the mold and the material into the heating chamber, and heat it to 140 degrees Celsius. The mold and the material are heated and cured in the heating chamber for 3...

Embodiment 2

[0045] Take a eucalyptus veneer with a moisture content of 12-15% (specification 1270*700*2.0mm, no dead knots), and use a cone-shaped roller on the surface to split the veneer on both sides, nailing out dense holes and hole spacing The eucalyptus veneer is less than 3.0 mm, relatively uniform, and the depth of one side is 1 mm. The eucalyptus veneer is steamed in boiling water for 20 minutes, filtered to remove the gum, and then the veneer is dried to a moisture content of 13%. Transfer to the sizing machine for sizing, immerse in the phenolic resin glue solution, soak for about 3 minutes. After dipping, the raw material is quantitatively (quantified according to the required density, in this case according to the density of 1.1) into the mold cavity of the molding machine, first press the predetermined shape, and then gradually pressurize to 42Mpa, when the pressure design value is finally reached , The material is dense and uniform. Clamp the mold, fix the material in the m...

Embodiment 3

[0047] Take poplar veneer with a moisture content of 15-20% (the veneer size is 1270*650*1.2mm, no dead knots), and use a diamond cone-shaped roller to split the veneer on both sides to make dense holes. The hole spacing is less than 5.0 mm, relatively uniform, and the depth of one side is 0.5 mm. It is immersed in the phenolic resin glue while being mechanically split for about 2 minutes. The dipped raw material quantitatively (quantified according to the required density, in this case according to the density of 1.0) is delivered to the mold cavity of the molding machine, first press the predetermined shape, and then gradually pressurize to 35Mpa, when the pressure is finally reached to the design value , The material is dense and uniform. Clamp the mold, fix the material in the mold, send the mold and the material into the heating chamber, and heat it to 140 degrees Celsius. The mold and the material are heated and cured in the heating chamber for 3 hours to complete the glu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com