Clamping device for magnet grinding and magnet grinding equipment

A clamping device and magnet technology, applied in the field of magnet grinding, can solve the problems of inconvenient processing, transportation and surface anti-corrosion treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

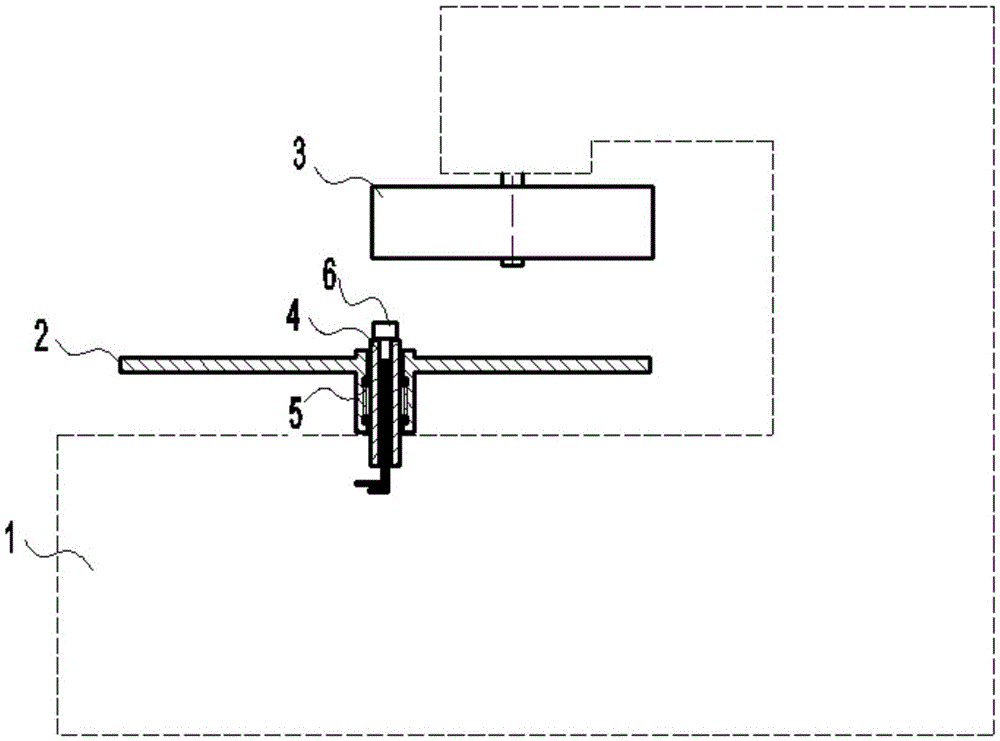

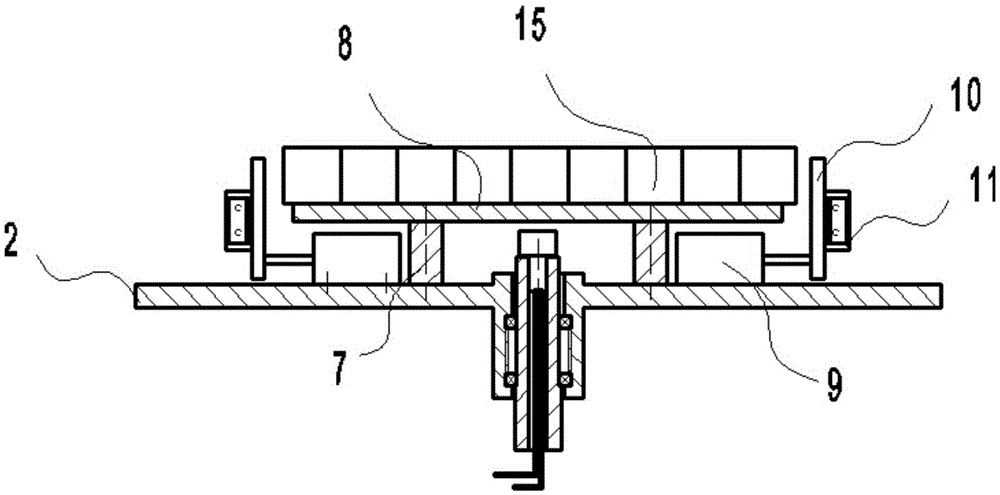

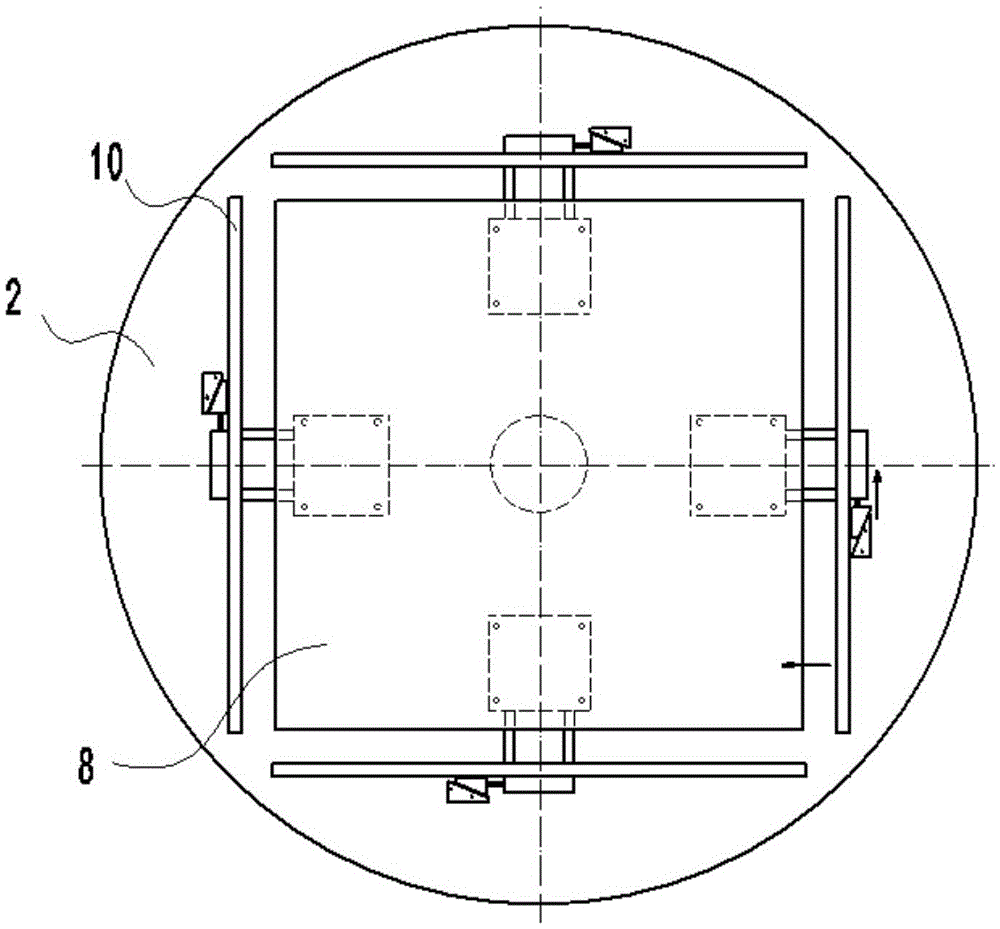

[0043] Hereinafter, embodiments of a clamping device for magnet grinding and a magnet grinding apparatus of the present invention will be described with reference to the accompanying drawings.

[0044] The embodiments described herein are specific embodiments of the present invention, are used to illustrate the concept of the present invention, are illustrative and exemplary, and should not be construed as limiting the embodiments of the present invention and the scope of the present invention. In addition to the embodiments described herein, those skilled in the art can also adopt other obvious technical solutions based on the contents disclosed in the claims and the description of the present application, and these technical solutions include any obvious technical solutions to the embodiments described herein. Alternative and modified technical solutions.

[0045] The accompanying drawings in the present specification are schematic diagrams to assist in explaining the concep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com