A stamping and welding production line for reinforced refrigerator racks

A stamping welding and production line technology is applied in the field of stamping and welding production lines for refrigerator reinforced racks, which can solve the problems of inability to guarantee welding quality, inability to combine stamping production lines, and inability to perform welding operations for a long time, so as to achieve shortened transportation distance, high synchronization, and guaranteed The effect of welding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

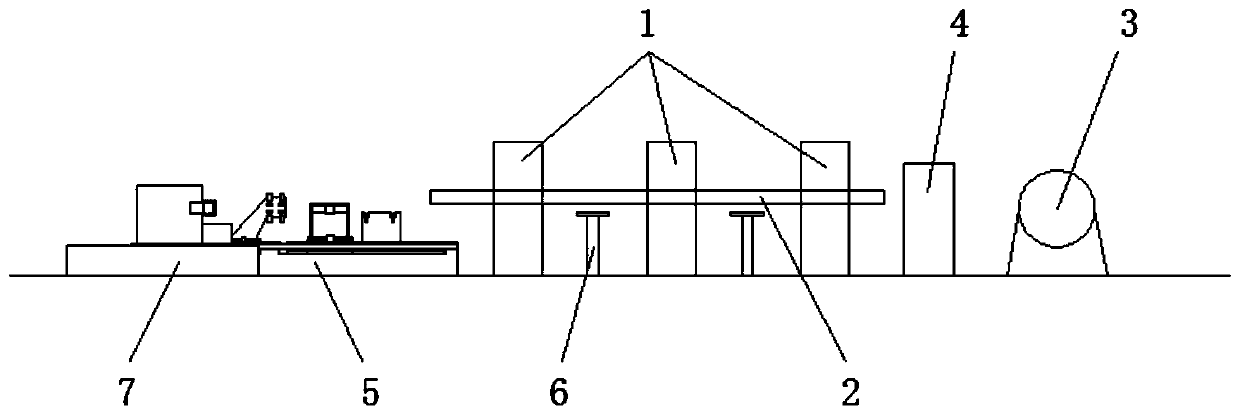

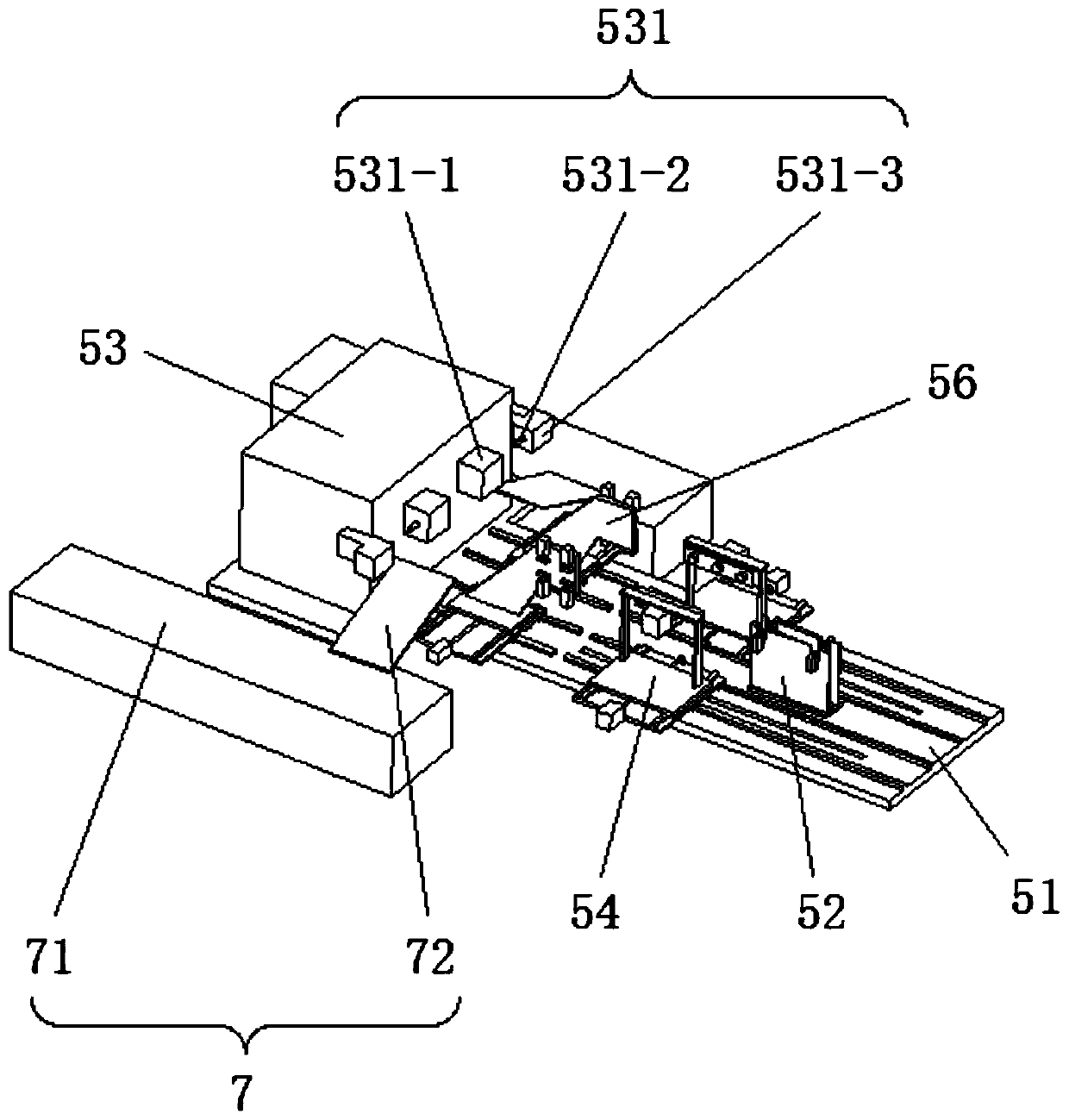

[0048] See Figure 1 to Figure 9 , the present invention is provided with feeding station, stamping station and welding station successively according to process step; Described stamping station is provided with a plurality of punch presses 1 and the first manipulator device 2 that are arranged along the forward direction of workpiece; The material station is provided with a material rack 3 for placing steel plate coils and a steel plate conveyor 4 for transporting steel plate coils into the punch press 1; the welding station is provided with a welding device 5;

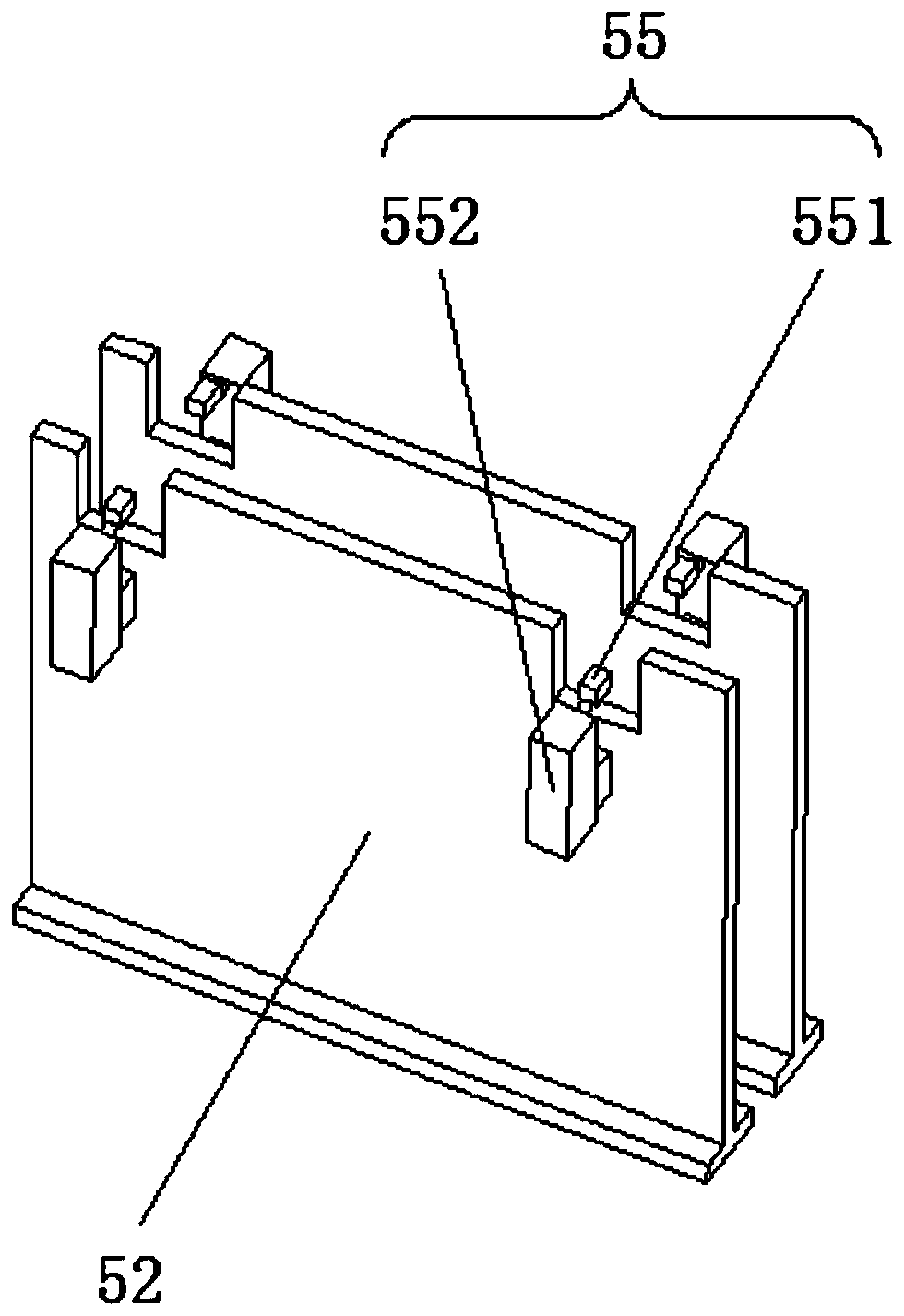

[0049] Described welding device 5 comprises frame 51; Described frame 51 is provided with support frame 52 and welding equipment 53 successively along workpiece advancing direction; The manipulator device 54; the welding equipment 53 has a welding head assembly 531; the welding head assembly 531 includes a fixed welding head 531-1 and a moving welding head 531-2 arranged oppositely; the moving welding head 531-2 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com