Method for performing welding in wire wound potentiometer

A welding method and potentiometer technology, applied in welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of difficult welding of microelectronic devices, and achieve the effect of improving stability, improving production efficiency, and realizing semi-automation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] specific implementation plan

[0021] The present invention will be further described in detail below through specific embodiments in conjunction with the accompanying drawings.

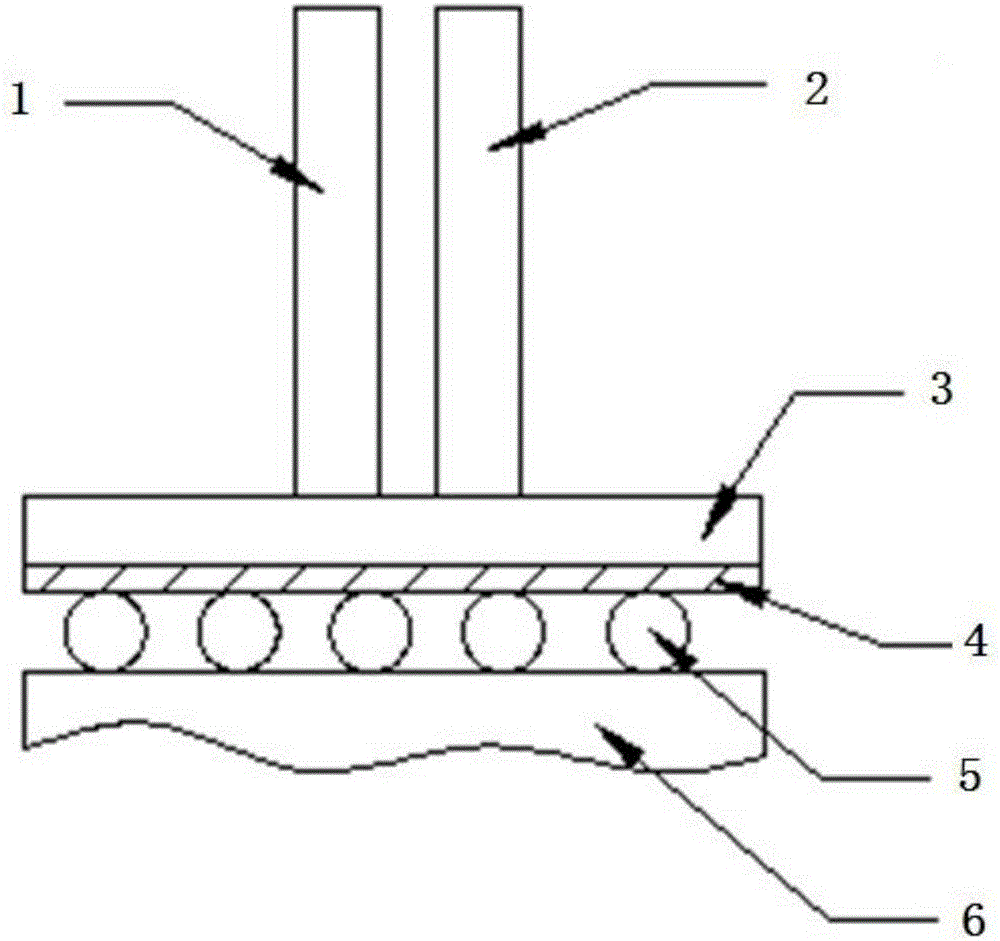

[0022] The lead-out method of the wire-wound potentiometer of the present invention is to utilize the high-temperature brazing of the resistance wire and the electrode sheet. The resistance wire is wound on the copper core coated with an insulating layer, and the electrode sheet can be directly connected to an external circuit, which simplifies the lead-out method. The main difficulties in welding the electrode sheet and the resistance wire are: the welding area is small, about 0.6mm*0.8mm, and the ordinary tin-plated solder method cannot be used to obtain a joint with excellent performance; the resistance wire is easy to break, and a single When the electrodes are welded on both sides, it is easy to damage the resistance wire or even damage the insulation layer on the copper core, resulting i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com