Additive manufacturing method for metal-based in-situ autogeny particle reinforced component

An in-situ self-generated, particle-enhanced technology, applied in additive processing and other directions, which can solve problems such as high viscosity, low viscosity, and low temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

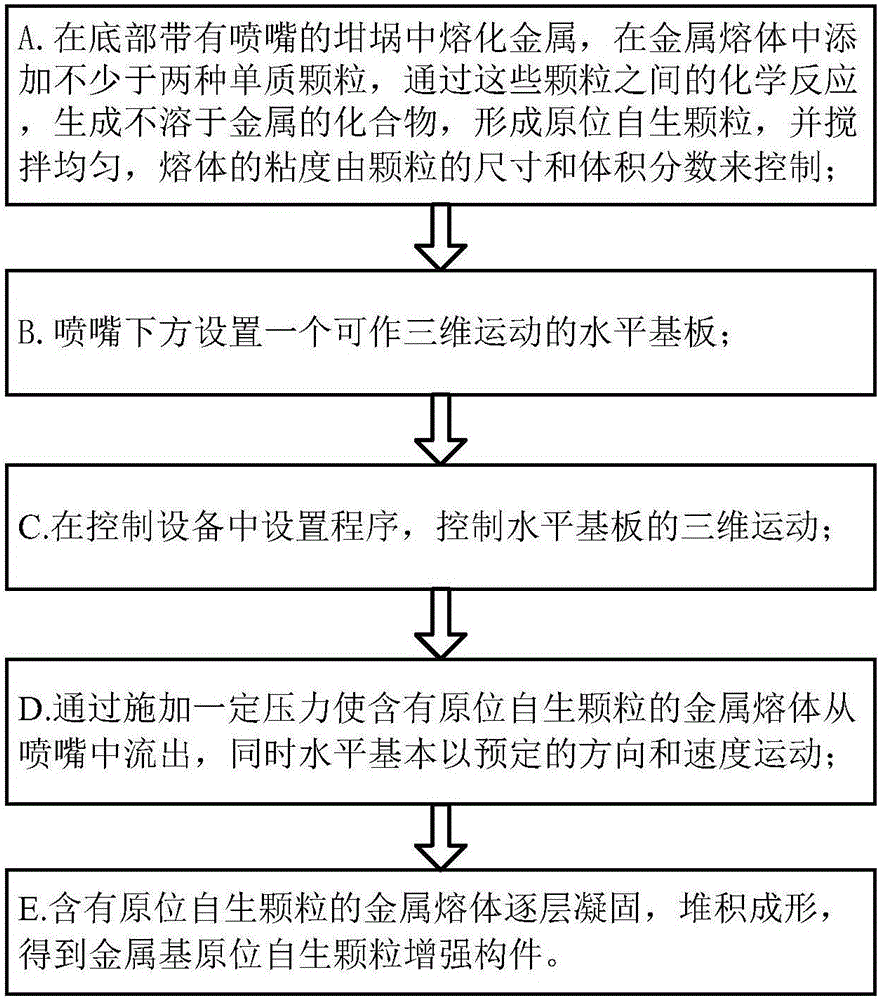

[0020] Embodiment 1: see figure 1 , figure 2 , an additive manufacturing method for a metal-based in-situ self-generated particle reinforced component, comprising the following steps:

[0021] A. Metal aluminum is melted in a crucible with a nozzle at the bottom, and the temperature is kept above 660°C. Ti with a diameter of 50 μm and C particles with a diameter of 1 μm are mixed at a mass ratio of Ti:C:Al=4:1:(20~ 45) Add the aluminum melt, and make the in-situ self-generated particles in the metal aluminum melt be evenly distributed by mechanical stirring, the heating method is resistance heating, and the metal melting is protected by an inert gas;

[0022] B. Set a horizontal base plate and its control equipment for three-dimensional movement under the nozzle. The inner diameter of the nozzle is 2mm, and the distance between the nozzle and the horizontal base plate is 10mm;

[0023] C. Set a predetermined program in the horizontal substrate control equipment to control t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com