sio2@ag core-shell structure composite conductive particles and preparation method thereof

A technology of conductive particles, core-shell structure, applied in metal processing equipment, liquid chemical plating, transportation and packaging, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

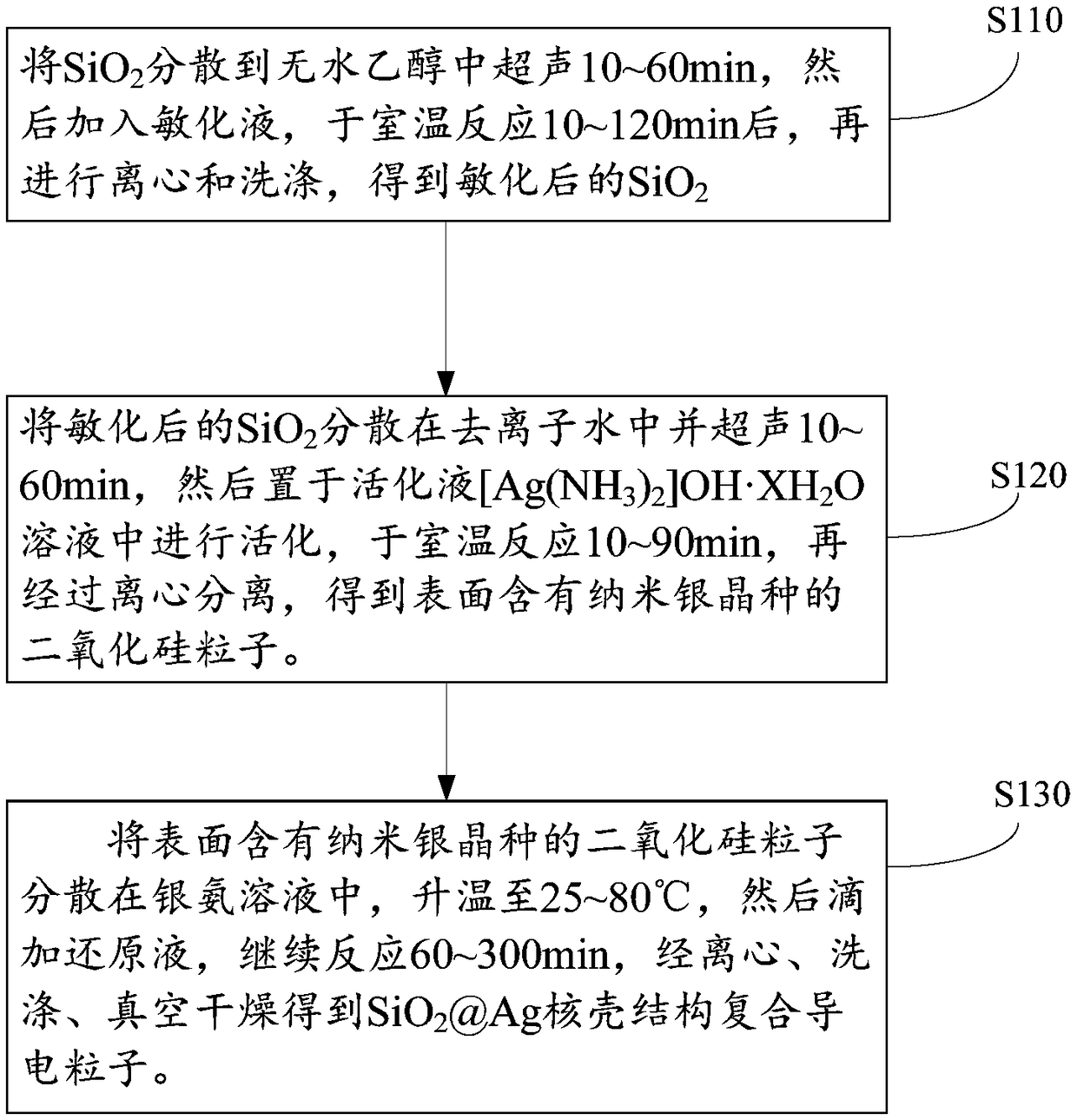

[0028] see figure 1 , an embodiment of Ag@SiO 2 A preparation method for composite conductive particles with a core-shell structure, comprising the steps of:

[0029] S110, SiO 2 Disperse in absolute ethanol and sonicate for 10-60 minutes, then add sensitizing solution, react at room temperature for 10-120 minutes, then centrifuge and wash to obtain sensitized SiO 2 .

[0030] In one embodiment, SiO 2 The particle size of SiO is between 10nm and 100μm, and the content of hydroxyl groups on its surface is between 0.2% and 8%. Preferably, SiO 2 The particle size is between 400nm and 10μm, and the surface hydroxyl content is between 1.5 and 4%.

[0031] In one embodiment, the sensitizing solution is selected from at least one of γ-aminopropyltriethoxysilane, γ-mercaptopropyltrimethoxysilane, mercaptoacetic acid, and stannous chloride, wherein the sensitizing solution The concentration is 0.01-10.0mol / L, the sensitizer and SiO 2 The mass ratio is 1:10~1:3.

[0032] In one ...

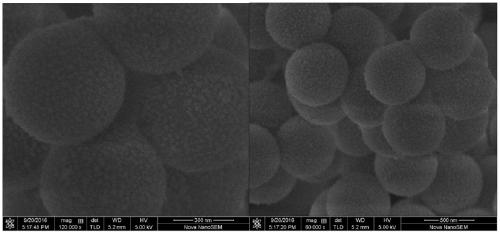

Embodiment 1

[0046] 1. Weigh 5.0g of 10μm SiO 2 , dissolved in 50ml of absolute ethanol, ultrasonic 10min.

[0047] 2. Prepare sensitizing solution: weigh 0.25g stannous chloride dihydrate, dissolve in 2ml concentrated hydrochloric acid, add water and dilute to 50ml.

[0048] 3. The above SiO 2 Mix with the sensitizing solution, and mechanically stir at 40°C for 20 minutes. Wash by centrifugation several times.

[0049] 4. Preparation of activation solution: weigh 0.3g of silver nitrate and dissolve in 50ml of deionized water. Add concentrated ammonia water dropwise to the silver nitrate solution, brown precipitate will start to form, continue to add concentrated ammonia water dropwise until the solution becomes clear.

[0050] 5. Place the sensitized silicon dioxide in the above activation solution, and stir mechanically at room temperature for 30 minutes. Wash by centrifugation several times.

[0051] 6. Preparation of silver plating solution: weigh 0.5g of silver nitrate and disso...

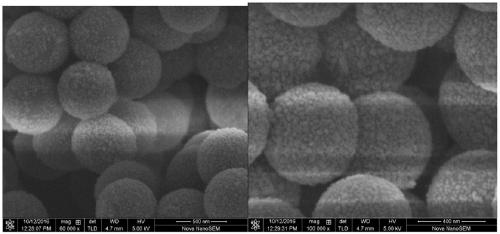

Embodiment 2

[0055] 1. Weigh 5.0g of 2μm SiO2 2 , dissolved in 50ml of absolute ethanol, ultrasonic 20min.

[0056] 2. Preparation of sensitization solution: Weigh 0.25g of γ-aminopropyltriethoxysilane, dissolve in 2ml of concentrated hydrochloric acid, and dilute to 50ml with water.

[0057] 3. The above SiO 2 Mix with the sensitizing solution, and mechanically stir at 40°C for 20 minutes. Wash by centrifugation several times.

[0058] 4. Preparation of activation solution: weigh 0.3g of silver nitrate and dissolve in 50ml of deionized water. Add concentrated ammonia water dropwise to the silver nitrate solution, brown precipitate will start to form, continue to add concentrated ammonia water dropwise until the solution becomes clear.

[0059] 5. Dissolve the sensitized silicon dioxide in the above activation solution, and stir mechanically at room temperature for 30 minutes. Wash by centrifugation several times.

[0060] 6. Preparation of silver plating solution: Weigh 0.60g of sil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com