Environment-friendly and automatic staining shell-making production line for precision casting

A precision casting and production line technology, applied in the direction of casting molding equipment, casting molds, casting mold components, etc., can solve the problems of large floor area, large dust, and large physical injuries of operators, and achieve the effect of reducing hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below according to the accompanying drawings and in conjunction with the embodiments.

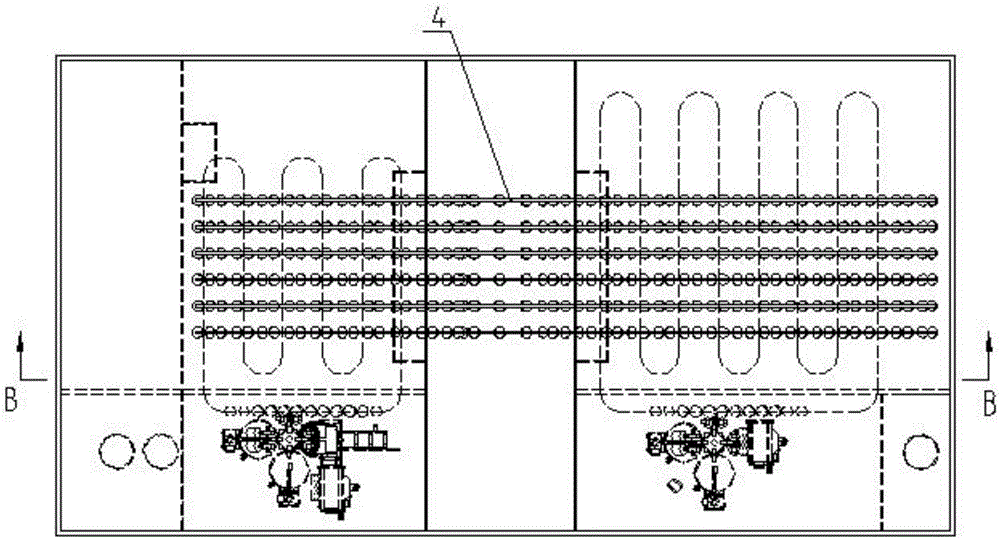

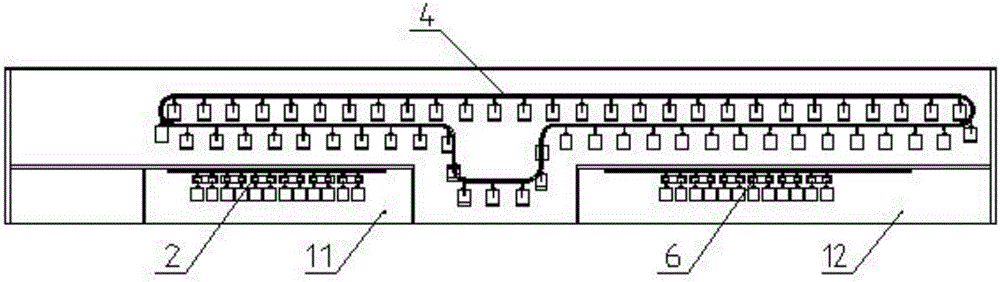

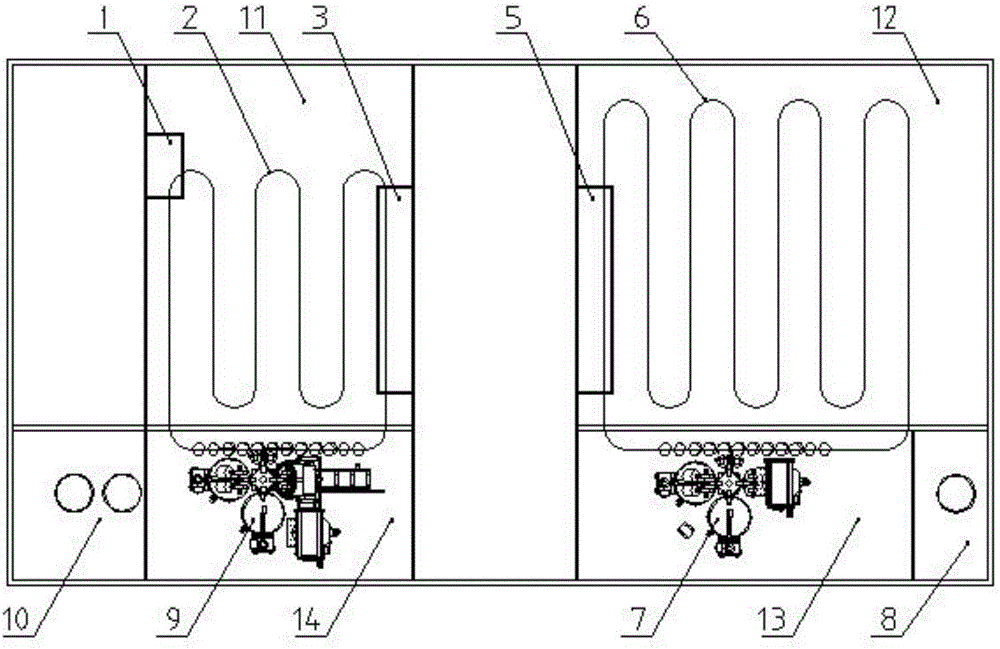

[0024] The precision casting environmental protection automatic dipping and shell making production line shown in the attached figure is set in the upper and lower spaces, and the lower space is equipped with a quick drying room Ⅰ11, a quick drying room Ⅱ12, an automatic slurrying room Ⅰ13, and an automatic slurrying room Ⅱ14 The fast drying room Ⅰ11 and the fast drying room Ⅱ12 are arranged at relative intervals; the fast drying room Ⅰ11 and the automatic slurry room Ⅱ14 are adjacent; the fast drying room Ⅱ12 and the automatic slurry room Ⅰ13 are adjacent; the automatic slurry line Ⅰ2 is operated in a horizontal plane Most of the circulation line I is set in the fast drying chamber I11, and the rest is set in the automatic slurry dipping room II14. The part of the automatic slurry dipping line I2 in the fast drying chamber I11 has a U-s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com