Ore crushing machine with multistage continuous crushing function

A pulverizer and secondary pulverization technology, applied in grain processing and other directions, can solve the problems of incapable of adapting to the development of energy-saving and consumption-reducing production, waste of energy and steel ball materials, abnormal wear and tear of steel balls, etc. The effect of prolonging the service life and improving the crushing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

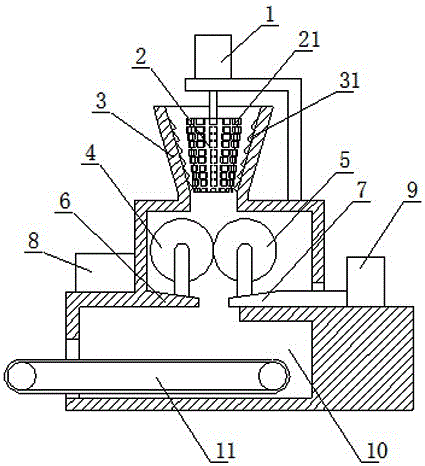

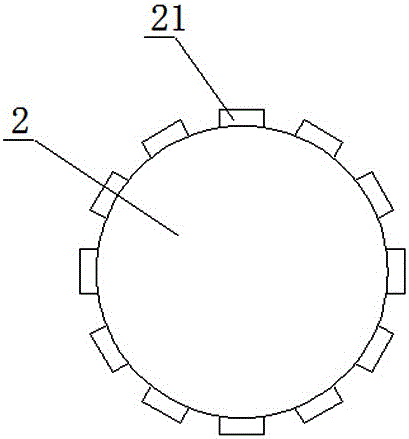

[0028] Such as figure 1 As shown, in this embodiment, an ore crusher capable of multi-stage continuous crushing is used for crushing ore, but not limited to crushing ore, including a primary crushing device, a secondary crushing device, and a secondary crushing device arranged from top to bottom in accordance with the ore flow direction. device and collection device, the primary crushing device includes an inverted conical passage 3 and a crushing roller 2 arranged in the passage 3, and the inner surface of the passage 3 is provided with several layers of A crushing teeth 31, such as figure 2 As shown, the outer surface of the crushing roller 2 is provided with several layers of B crushing teeth 21, and the crushing roller 2 is connected with the A driving device 1 through transmission. The collected ore enters the interior of the present invention from the channel 3, and the A driving device 1 is started to drive the crushing roller 2 to rotate. 21 squeeze each other so tha...

Embodiment 2

[0032] On the basis of the above embodiments, in this embodiment, the surfaces of the driving roller 4 and the driven roller 5 are provided with anti-slip stripes, so as to prevent the driving roller or the driven roller 5 from slipping with the material and affect the crushing efficiency .

Embodiment 3

[0034] On the basis of the above embodiments, in this embodiment, the B support platform 7 is slidably arranged above the collection device, and the B support platform 7 is connected to the C driving device 9 through transmission, and the C driving device 9 adopts a hydraulic cylinder. The piston rod of the hydraulic cylinder is in transmission connection with the B support platform 7 . In this way, the distance between the driving roller and the driven roller can be adjusted, which is conducive to convenient adjustment according to the particle size of the required material, thereby helping to save the use cost of the equipment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com