Preparation method of hydrophobic silica nano sphere-supported palladium-based catalyst

A technology of nano-silicon balls and catalysts, applied in chemical instruments and methods, physical/chemical process catalysts, organic compound/hydride/coordination complex catalysts, etc. easy-to-get effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] (1) Mix NP-7, n-butanol and cyclohexane with stirring at room temperature to obtain a transparent solution A,

[0026] (2) adding ammonia dropwise to the above-mentioned transparent solution to form a microemulsion;

[0027] (3) 5.21g of methyl orthosilicate, phenyltrimethoxysilane and vinyltriethoxysilane were mixed uniformly to form a mixed solution. Under vigorous stirring, the mixed solution was added dropwise into the microemulsion. The ratio of the amount of each component in the final reaction solution (solution B) is, methyl orthosilicate: NP-7: n-butanol: cyclohexane: H 2 O: NH 3 h 2 O: phenyltrimethoxysilane: vinyltriethoxysilane = 1:1:4.5:15:16:1:0.2:0.05 and continue stirring at room temperature for 12h.

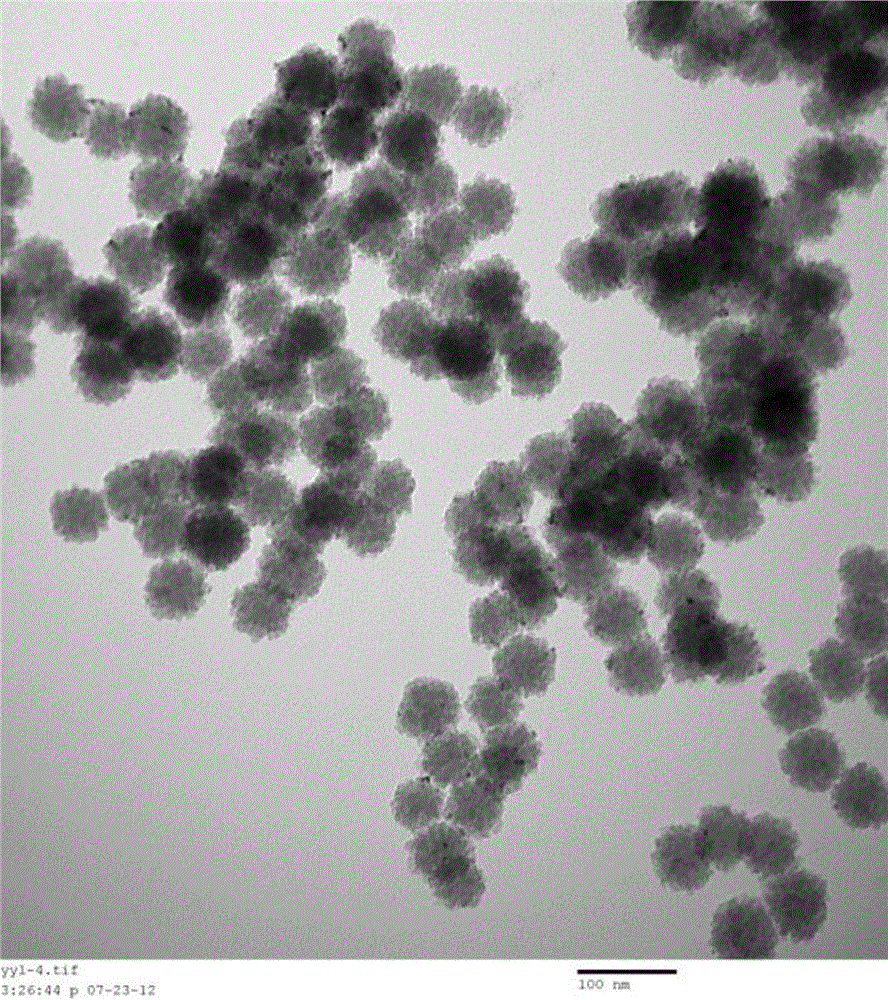

[0028] (4) After adding 10 mL of ethanol to break the emulsion, reflux washing with 50 mL of ethanol three times to remove the surfactant, and vacuum drying at 50°C to obtain nano-silicon spheres containing organic groups and reducing groups with a wat...

Embodiment 2-12

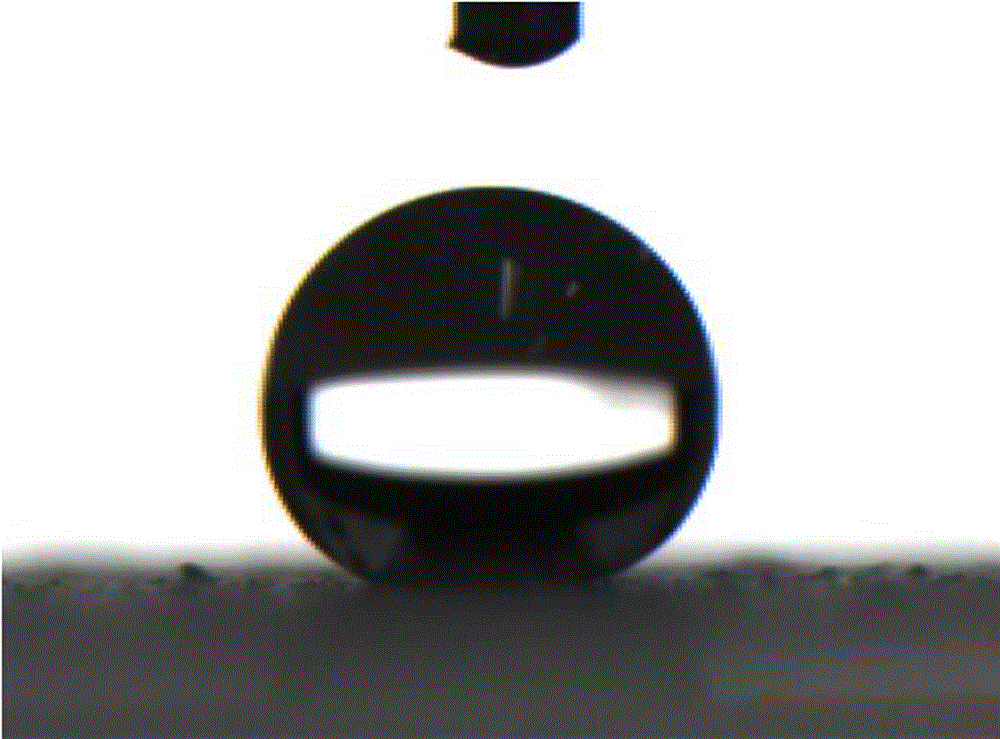

[0030] Change the addition of n-butanol, cyclohexane, water, phenyltrimethoxysilane and vinyltriethoxysilane in Example 1, and prepare hydrophobic nano silicon spheres under other conditions. The results are shown in the following table:

[0031] .

Embodiment 13-16

[0033] Change the amount of demulsification ethanol and reflux ethanol in the post-treatment process in Example 1, and do not allow temperature drying, and prepare nano-silicon spheres with other conditions unchanged. The results are shown in the table below. It can be seen from the results that the post-treatment conditions have no obvious effect on the hydrophobicity of the prepared materials.

[0034] .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com