Preparation method of ginger extract

A ginger extract and ginger technology are applied in the field of ginger extract preparation, can solve the problems of insignificant bacteriostatic effect and low utilization rate of the ginger extract, and achieve the effects of high pharmacological activity, thorough response and strong controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

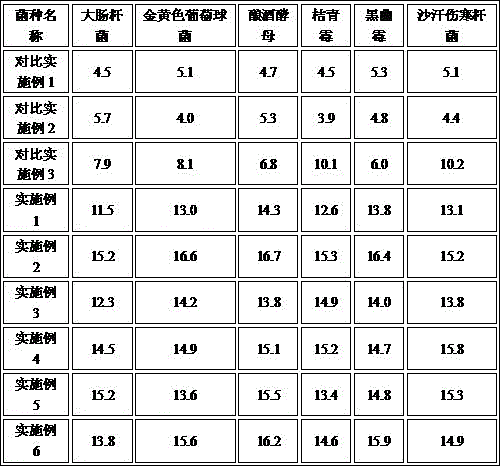

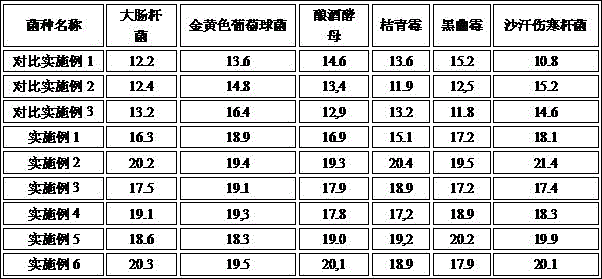

Examples

Embodiment 1

[0037] Weigh 1.1kg of sun-dried ginger and crushed ginger, put them into an enzymatic hydrolysis container, add 3 times the amount of drinking water, stir, heat, control the temperature at 60°C, adjust the pH to 6.0 with dilute hydrochloric acid, add 60g of fiber Vegetable complex enzyme, enzymatic hydrolysis for 6 hours, filtered, distilled in a reduced-pressure evaporator until the relative density of the solution was 1.19, added an appropriate amount of absolute ethanol to make the ethanol concentration of the solution reach 80%, stirred, left standing for 24 hours, filtered, and the filtrate Concentrate to 206.2g.

Embodiment 2

[0039] Weigh 1.1kg of sun-dried ginger, chop it, put it into an enzymatic hydrolysis container, add 1 times the amount of drinking water, stir, heat, control the temperature at 40°C, adjust the pH to 4.0 with dilute hydrochloric acid, add 5g of fiber Vegetable compound enzyme, enzymatic hydrolysis for 2 hours, filtered, distilled in a vacuum evaporator until the relative density of the solution was 1.11, added an appropriate amount of 95% ethanol to make the ethanol concentration of the solution reach 60%, stirred, left standing for 6 hours, filtered, and the filtrate Concentrate to 202.5g.

Embodiment 3

[0041] Weigh 1.1kg of sun-dried ginger, chop it, put it into an enzymatic hydrolysis container, add 2 times the amount of drinking water, stir, heat, control the temperature at 50°C, adjust the pH to 4.5 with dilute hydrochloric acid, add 30g of fiber Vegetable complex enzyme, enzymatic hydrolysis for 4 hours, filtered, distilled in a reduced-pressure evaporator until the relative density of the solution was 1.15, added an appropriate amount of 95% ethanol to make the ethanol concentration of the solution reach 70%, stirred, let stand for 12 hours, filtered, and the filtrate Concentrate to 200.8g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com