Seaweed gum vegetable soft capsule shell and preparation method

A seaweed gel and soft capsule technology, which is applied in capsule delivery, pharmaceutical formulations, medical preparations of non-active ingredients, etc., can solve the problems of capsule shell rupture, high cross-linking degree, amino acid cross-linking reaction, etc., to achieve less pollution, The effect of high chemical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Embodiment 1: a kind of vegetable capsule shell of soft capsule, it comprises the raw material of following weight ratio:

[0032] Agar 3Kg, Alginate 4Kg, κ-Carrageenan 10Kg, Sorbitol 25Kg, Glycerin 15Kg, CaCl 2 0.02Kg, water 43Kg.

[0033] Vegetable capsule shells can be prepared by the existing soft capsule production method. The compressed capsules are sent to a drying room for drying, the drying temperature is set at 40° C., the relative air humidity is controlled at 30%, and the drying time is about 3 hours.

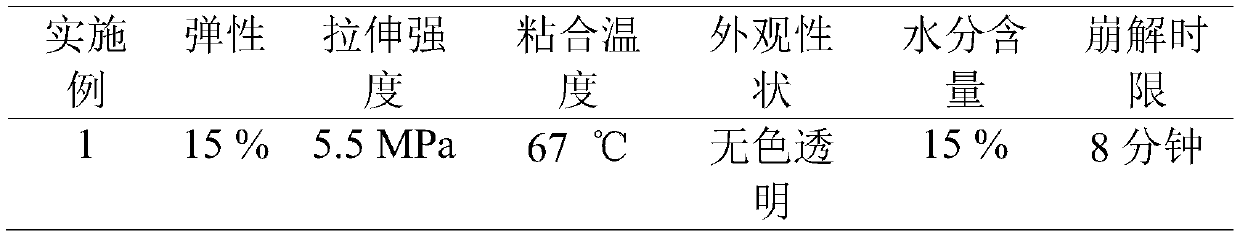

[0034] Evaluate the rubber elasticity, strength and bonding temperature of the product of Example 1, and measure the appearance properties, moisture content, disintegration time limit and other indicators for the soft capsule samples produced in a small trial.

[0035] The results are shown in Table 1:

[0036] The capsule shell property of table 1 embodiment 1

[0037]

Embodiment 2

[0038] Embodiment 2: a kind of vegetable capsule shell of soft capsule, it comprises the raw material of following weight ratio:

[0039] Agar 2Kg, Alginate 8Kg, κ-Carrageenan 8Kg, Sorbitol 30Kg, Glycerin 10Kg, ZnCl 2 0.03Kg, water 42Kg.

[0040] Vegetable capsule shells can be prepared by the existing soft capsule production method. The compressed capsules are sent to a drying room for drying, the drying temperature is set at 42° C., the relative air humidity is controlled at 35%, and the drying time is about 3 hours.

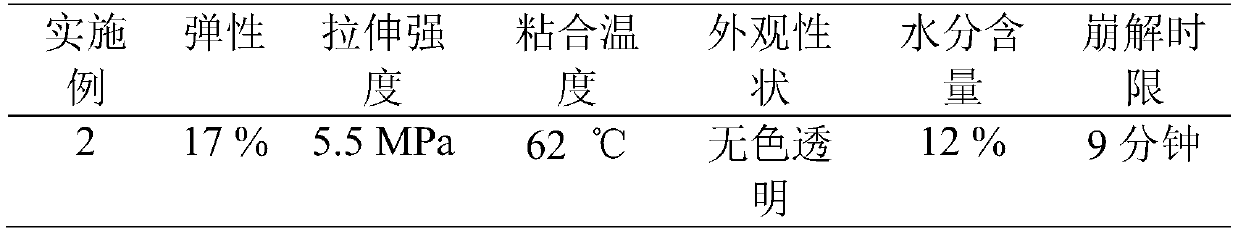

[0041] Evaluate the rubber elasticity, strength and bonding temperature of the product of Example 2, and carry out the measurement of indicators such as appearance properties and moisture content to the soft capsule sample produced in a small trial.

[0042] The results are shown in Table 2:

[0043] The capsule shell property of table 2 embodiment 2

[0044]

Embodiment 3

[0045] Embodiment 3: a kind of vegetable capsule shell of soft capsule, it comprises the raw material of following weight ratio:

[0046] Agar 4Kg, Alginate 6Kg, κ-Carrageenan 6Kg, Sorbitol 22Kg, Glycerin 18Kg, ZnCl 2 0.02Kg, water 44Kg.

[0047] Vegetable capsule shells can be prepared by the existing soft capsule production method. The compressed capsules are sent to a drying room for drying, the drying temperature is set at 45° C., the relative air humidity is controlled at 40%, and the drying time is about 2 hours.

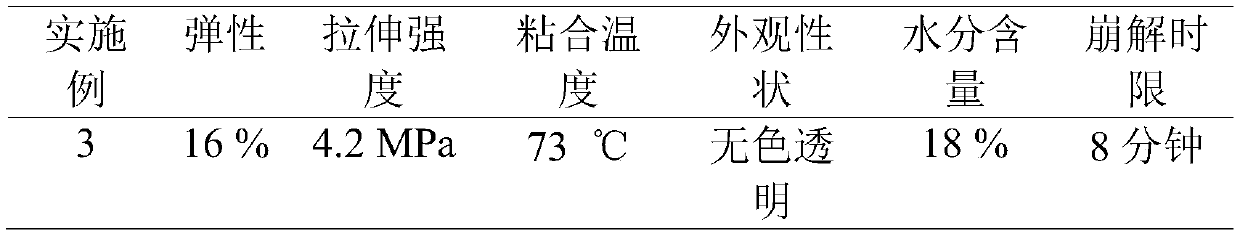

[0048] Evaluate the rubber elasticity, strength and bonding temperature of the product of Example 3, and measure the appearance properties, moisture content, disintegration time limit and other indicators for the soft capsule samples produced in a small trial.

[0049] The results are shown in Table 3:

[0050] The capsule shell property of table 3 embodiment 3

[0051]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com