Fish oil microcapsule and preparation method thereof

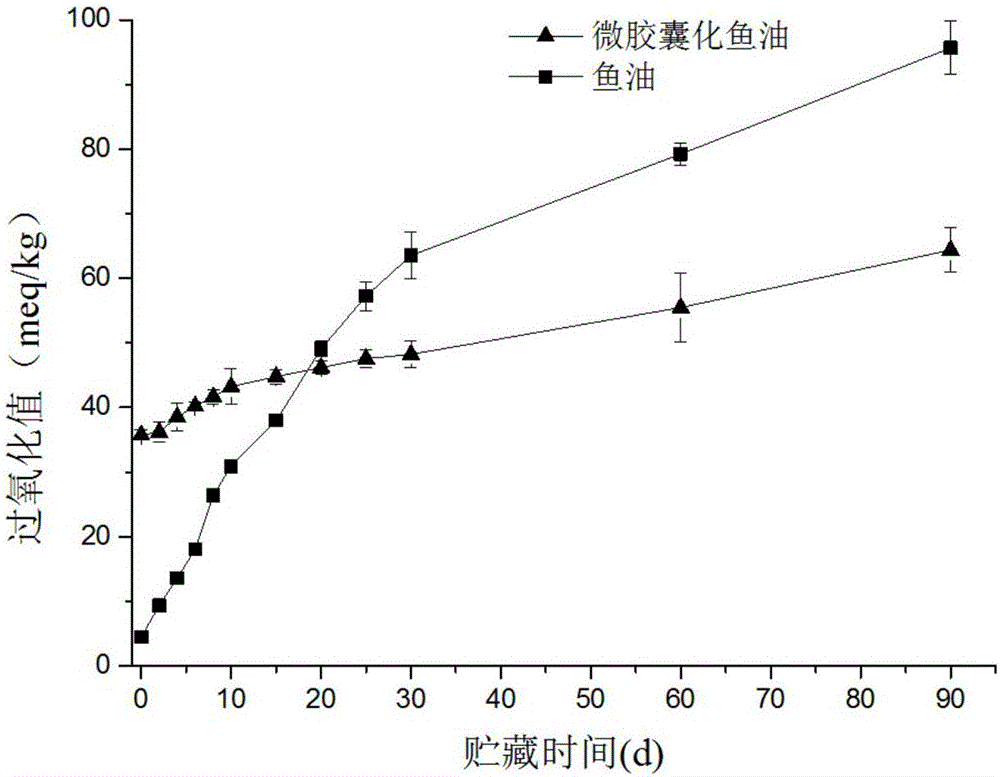

A technology of microcapsules and fish oil, which is applied in the field of aquatic product processing, can solve the problems of difficult large-scale industrial production, lack of masking odor, and inability to protect fish oil, etc., achieve good protection, good fluidity, and improve oxidation stability and thermal stability effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] (1) 0.50g chitosan (chitosan molecular weight is 40kDa, degree of deacetylation is 85%) is dissolved in 1% acetic acid solution, is stirred 2h under 500rpm and obtains the wall material solution that concentration is 0.5%; (2) Add 0.0907g Tween 80 to 100mL chitosan solution, stir until dissolved, then add 0.25g fish oil (additional 0.1% vitamin E to fish oil) and 0.0093g Span 80, stir at 2000rpm for 2h, then carry out high-pressure homogenization (3) Spray-dry the emulsion to obtain fish oil microcapsules, the inlet air temperature is 200°C, and the feed rate is 400mL / h.

[0030] The fish oil microcapsules prepared in this example were subjected to moisture content, particle size, fluidity measurement, entrapment rate measurement, and oxidation stability measurement, and the method was as follows.

[0031] Moisture content determination method: The moisture content of the microcapsule sample is determined with reference to the GB / T 5528-2008 method.

[0032] Particle s...

Embodiment 2

[0040] (1) 2.00g chitosan (chitosan molecular weight is 60kDa, degree of deacetylation is 80%) is dissolved in 1% acetic acid solution, is stirred 1h under 1000rpm and obtains the wall material solution that concentration is 2.0%; (2) Add 0.9065g Tween 80 to 100mL chitosan solution, stir until dissolved, then add 4.00g fish oil (additional 0.1% vitamin E to fish oil) and 0.0935g Span 80, stir at 2500rpm for 1.5h, and then perform high pressure Homogeneous emulsification to obtain a stable and uniform emulsion, the homogenization pressure is 50MPa, and the time is 3min; (3) The emulsion is spray-dried to obtain fish oil microcapsules, the inlet air temperature is 160°C, and the feed rate is 600mL / h.

[0041] The fish oil microcapsules prepared in this example were subjected to moisture content, particle size, fluidity measurement, entrapment rate measurement, and oxidation stability measurement, and the method was as follows.

[0042] Moisture content determination method: The mo...

Embodiment 3

[0051] (1) 1.00g chitosan (chitosan molecular weight is 20kDa, degree of deacetylation is 80%) is dissolved in 1% acetic acid solution, stirs 4h under 400rpm and obtains the wall material solution that concentration is 1%; (2) Add 0.3173g Tween 80 to 100mL chitosan solution, stir until dissolved, then add 0.67g fish oil (additional 0.1% vitamin E to fish oil) and 0.0327g Span 80, stir, high-speed shear, high-pressure homogenization Stable and uniform emulsion was obtained by emulsification, and the homogeneous pressure was 35 MPa; (3) the emulsion was spray-dried to obtain fish oil microcapsules, and the air inlet temperature was 180°C.

[0052] The fish oil microcapsules prepared in this example were subjected to moisture content, particle size, fluidity measurement, entrapment rate measurement, and oxidation stability measurement, and the method was as follows.

[0053] Moisture content determination method: The moisture content of the microcapsule sample is determined with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com