Linseed oil emulsion taking compounded linseed gum as emulsifier and preparation method of linseed oil emulsion

A technology of linseed oil and emulsifier, applied in the fields of edible oil/fat, food science, application, etc., can solve the problems of being easily affected by the environment, the thickness of the mask is thin, the system is unstable, etc., and achieves good dispersion and high utilization. , the effect of high oxidation stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

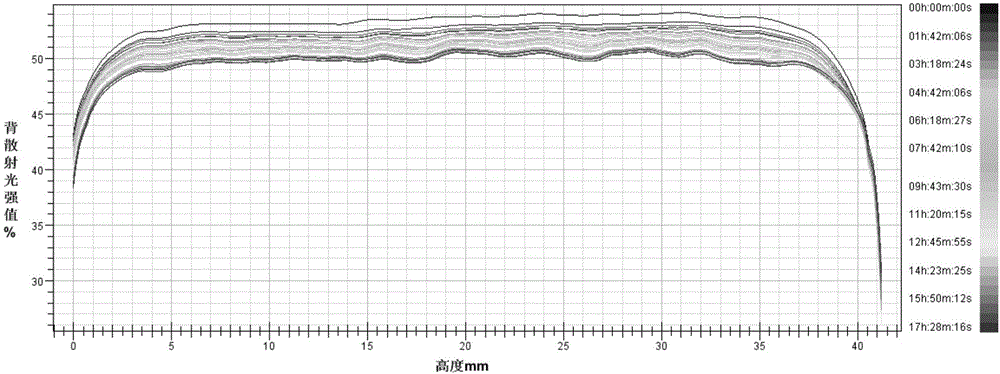

Image

Examples

Embodiment 1

[0036] Embodiment 1, preparation linseed oil emulsion

[0037] 1) Take a mixture of gum arabic (molecular weight 200,000-600,000) and flax gum (molecular weight 2.6-3.5 million) as an emulsifier (mass ratio 7:3), add glycerin to wet (the amount ratio of emulsifier and glycerin is 2:1), add sterile pure water to the mixed material to make an aqueous solution of 2.5wt% emulsifier, stir magnetically at 60°C for 1 hour and then swell overnight (temperature is about 25°C, 10h) to ensure full hydration.

[0038] 2) Using linseed oil as the oil phase, according to the oil-water ratio of 1:4 (v / v), slowly add the oil phase to the water phase at a shear rate of 10,000 rpm and a shear time of 2 min to form a primary emulsion.

[0039] 3) Use a high-pressure homogenizer to carry out secondary homogenization, the pressure of the primary homogenization is 350 bar, and the pressure of the secondary homogenization is 50 bar, and a stable linseed oil emulsion is prepared.

[0040] The partic...

Embodiment 2

[0046] Embodiment 2, preparation linseed oil emulsion

[0047]1) Take a mixture of gum arabic (molecular weight 200,000-600,000) and flax gum (molecular weight 2.6-3.5 million) as an emulsifier (mass ratio 2:1), add glycerin to wet (the amount ratio of emulsifier and glycerin is 3:2), add sterile pure water to the mixed material to make an aqueous solution of 1.5wt% emulsifier, stir magnetically at 60°C for 1 hour and then swell overnight (temperature is about 25°C, 10h) to ensure full hydration.

[0048] 2) Using linseed oil as the oil phase, according to the oil-water ratio of 1:2 (v / v), slowly add the oil phase into the water phase at a shear rate of 20,000 rpm and a shear time of 2 min to form a primary emulsion.

[0049] 3) Use a high-pressure homogenizer to carry out secondary homogenization, the pressure of the primary homogenization is 250 bar, and the pressure of the secondary homogenization is 50 bar, and a stable linseed oil emulsion is prepared.

[0050] The parti...

Embodiment 3

[0055] Embodiment 3, preparation linseed oil emulsion

[0056] 1) Take a mixture of gum arabic (molecular weight 200,000-600,000) and flax gum (molecular weight 2.6-3.5 million) as an emulsifier (mass ratio 3:1), add glycerin to wet (the ratio of emulsifier to glycerin is 3:1), add sterile pure water to the mixed material to make an aqueous solution of 2wt% emulsifier, stir magnetically at 60°C for 1 hour and then swell overnight (temperature is about 25°C, 10h) to ensure full hydration.

[0057] 2) Using linseed oil as the oil phase, according to the oil-water ratio of 1:3 (v / v), slowly add the oil phase into the water phase at a shear rate of 15000 rpm and a shear time of 2 min to form a primary emulsion.

[0058] 3) Use a high-pressure homogenizer to carry out secondary homogenization, the pressure of the primary homogenization is 300 bar, and the pressure of the secondary homogenization is 50 bar, and a stable linseed oil emulsion is prepared.

[0059] The particle size o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com