Preparation method of novel pesticide bovine serum albumin-thiacloprid nanoparticles

A bovine serum albumin and nanoparticle technology, which is applied in the field of preparation of new-type pesticide bovine serum albumin-thiacloprid nanoparticles, can solve the problems of difficult transportation, difficult long-term storage, obvious burst release phenomenon, etc. The effect of lower equipment requirements and lower manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

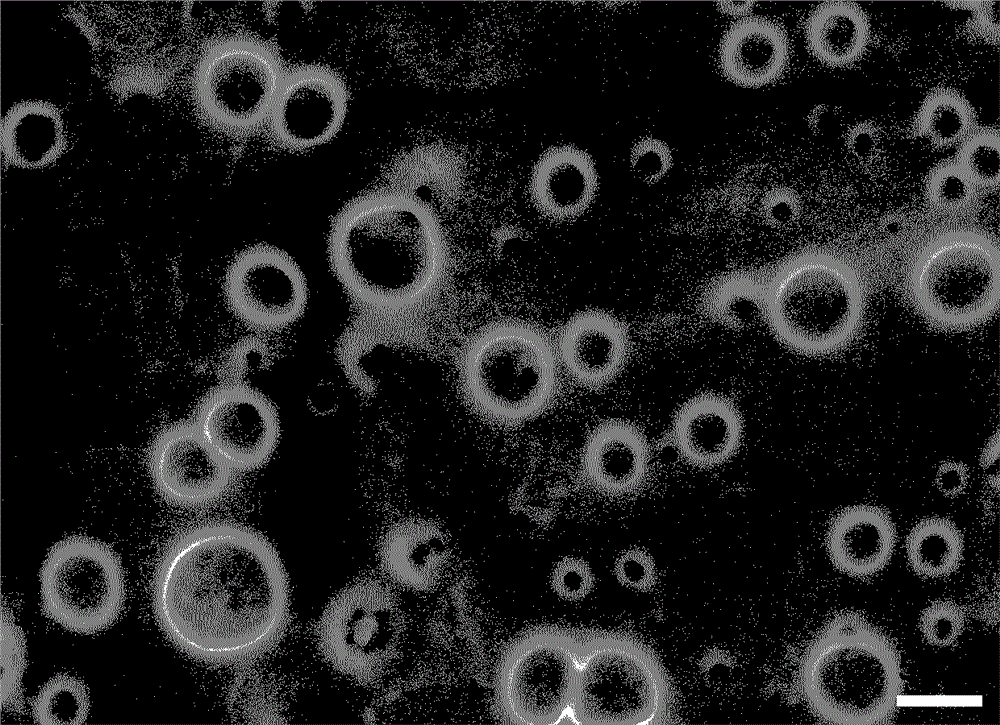

Image

Examples

Embodiment 1

[0025] (1) Take 0.08g of bovine serum albumin in 4ml of double distilled water to prepare the water phase, 50 o C water bath 30min, obtain clear and transparent bovine serum albumin aqueous solution;

[0026] (2) Take another 1mg of thiacloprid, add 0.167ml of acetonitrile for ultrasonic dissolution for 5min, and prepare 6mg / mL thiacloprid-acetonitrile oil phase;

[0027] (3) Adjust the speed of the water phase to 1000rpm, add the thiacloprid-acetonitrile oil phase drop by drop under high-speed stirring, emulsify for 30min, and take out the emulsion quickly within 0-4 o Cool at 10°C for 10min, then take out the ultrasonic wave for 10min to obtain bovine serum albumin-thiacloprid supermicroemulsion;

[0028] (4) Dialyze the supermicroemulsion dialysis membrane (MWCO=5000) overnight, take out the dialysate, freeze it, and dry it to obtain a white powder, that is, thiacloprid albumin nanoparticles.

Embodiment 2

[0030] (1) Take 0.08g of bovine serum albumin in 4ml of double distilled water to prepare the water phase, 50 o C water bath 30min, obtain clear and transparent bovine serum albumin aqueous solution;

[0031] (2) Take another 2 mg of thiacloprid, add 0.334 ml of acetonitrile for ultrasonic dissolution for 5 minutes, and prepare 6 mg / mL thiacloprid-acetonitrile oil phase;

[0032] (3) Adjust the rotation speed of the water phase to 1000rpm, add the thiacloprid-acetonitrile oil phase dropwise under high-speed stirring, emulsify for 40min, and take out the emulsion quickly within 0-4 o Cool at 10°C for 10min, then take out the ultrasonic wave for 10min to obtain bovine serum albumin-thiacloprid supermicroemulsion;

[0033] (4) Dialyze the supermicroemulsion dialysis membrane (MWCO=5000) overnight, take out the dialysate, freeze it, and dry it to obtain a white powder, that is, thiacloprid albumin nanoparticles.

Embodiment 3

[0035] (1) Take 0.08g of bovine serum albumin in 4ml of double distilled water to prepare the water phase, 50 o C water bath 30min, obtain clear and transparent bovine serum albumin aqueous solution;

[0036] (2) Take another 3 mg of thiacloprid, add 0.501 ml of acetonitrile to ultrasonically dissolve for 10 min, and prepare 6 mg / mL thiacloprid-acetonitrile oil phase;

[0037] (3) Adjust the rotation speed of the water phase to 1200rpm, add the thiacloprid-acetonitrile oil phase drop by drop under high-speed stirring, emulsify for 40min, and take out the emulsion quickly within 0-4 o Cooling for 5min under C, then take out the ultrasonic wave for 10min to obtain bovine serum albumin-thiacloprid supermicroemulsion;

[0038] (4) Dialyze the supermicroemulsion dialysis membrane (MWCO=5000) overnight, take out the dialysate, freeze it, and dry it to obtain a white powder, that is, thiacloprid albumin nanoparticles.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com