One-dimensional photonic crystal beam structure band gap designing method based on wavelet finite element model

A wavelet finite element, phononic crystal technology, applied in design optimization/simulation, calculation, instrument, etc., can solve problems such as poor convergence, long calculation time, inability to accurately calculate phononic crystals, etc., to ensure accuracy and performance. fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

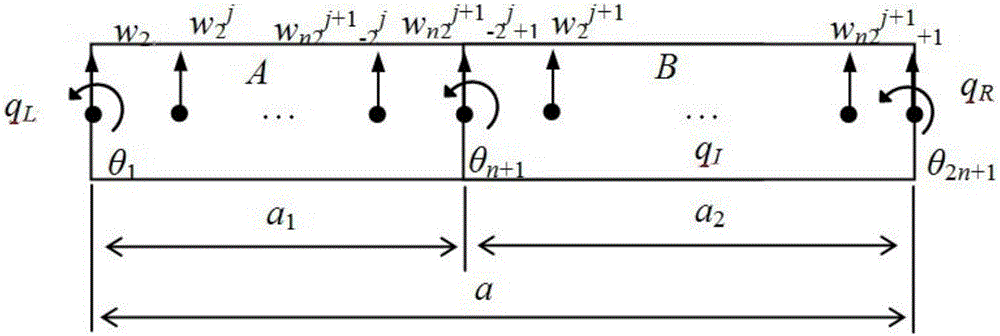

[0096] Embodiment 1: This embodiment mainly verifies the high performance (fastness, stability, and convergence) of the calculation of the wavelet finite element model for the calculation of the band gap of the one-dimensional phononic crystal beam structure. for figure 1 The 1D phononic crystal beam structure shown. The material of part A is copper, and the material of part B is epoxy resin. The copper and epoxy resin are arranged alternately in a lattice, and the filling rate is a 1 / a 2 =1 / 1, lattice constant a=150mm. The elastic constants of the material of copper and epoxy resin are as Figure 5 shown.

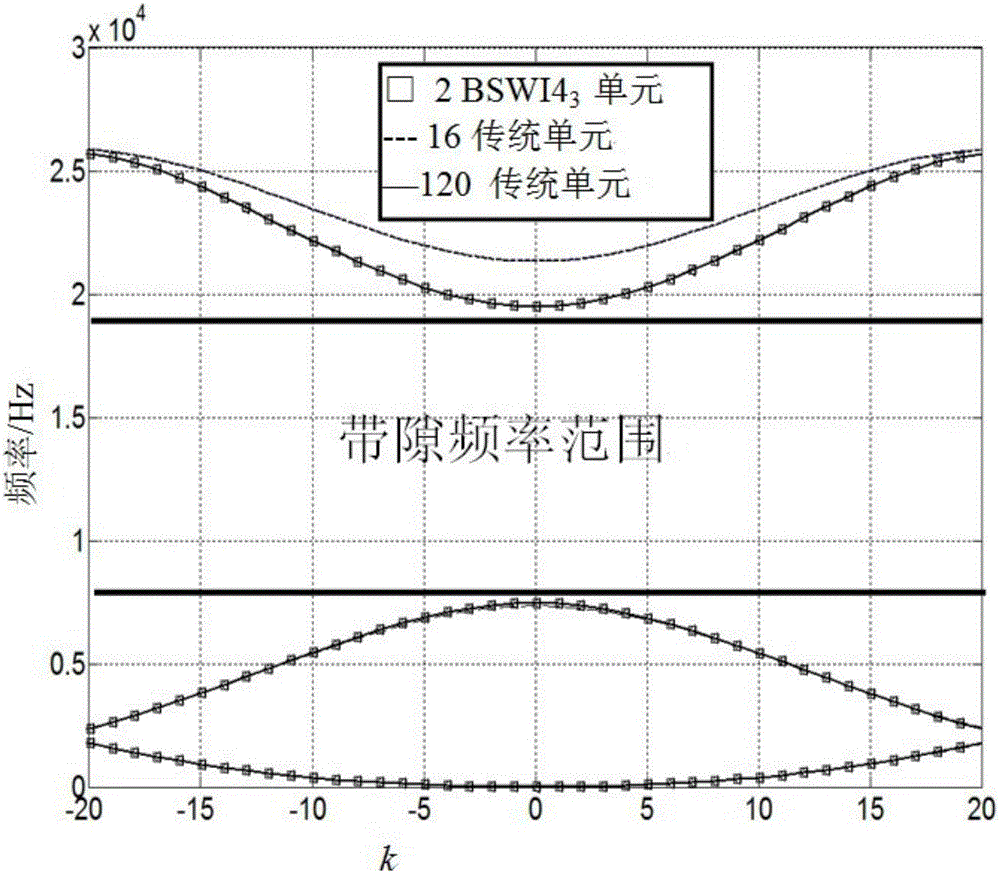

[0097] In order to verify the effectiveness of the wavelet finite element method in calculating the bandgap of phononic crystal beam structures, two BSWI4 3 Beam elements (20 degrees of freedom), 16 and 120 conventional beam elements (34 and 242 degrees of freedom) calculate the bandgap properties of 1D phononic crystal beams. The result is as figure 2 , where the...

Embodiment 2

[0099] Embodiment 2: This embodiment mainly provides the scale range of the one-dimensional phononic crystal beam structure with a wider bandgap calculated by using the wavelet finite element model. The material of part A is copper, and the material of part B is epoxy resin. For the material parameters, see Figure 5 . Without loss of generality, the fixed structural parameters are: a=100mm.

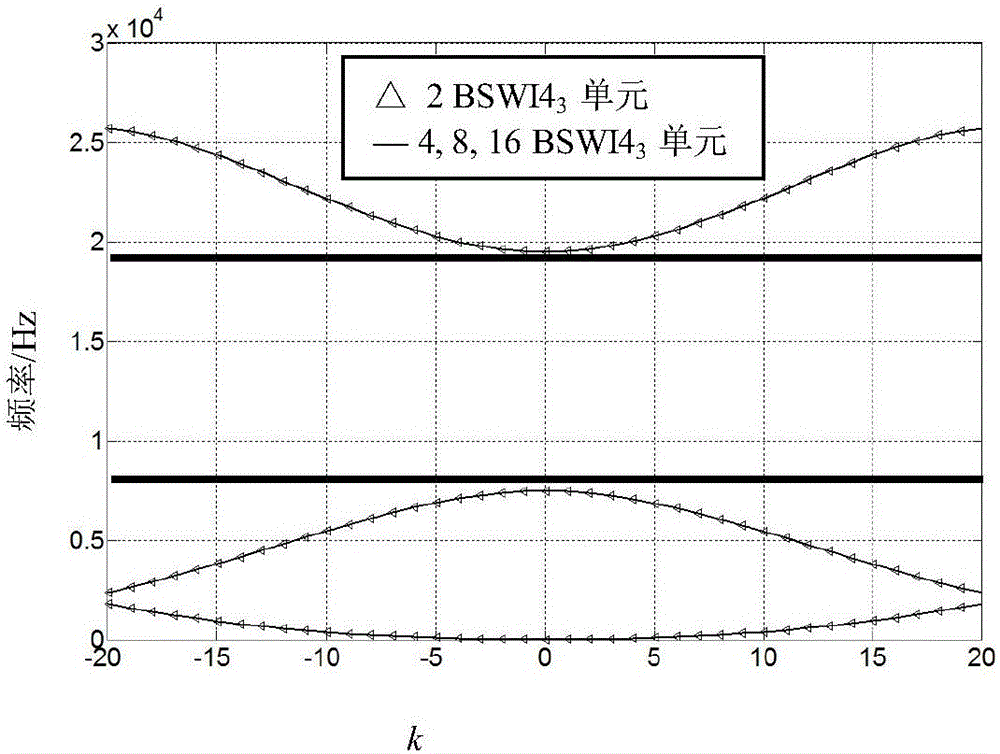

[0100] Adoption, 2 BSWI4 3 The beam element calculates the bandgap of phononic crystals. In order to obtain the bandgap characteristics that meet the requirements of a specific frequency band, the structural size of the one-dimensional phononic crystal beams is continuously calculated and adjusted. Under the premise of a fixed lattice constant, the relationship between the geometric dimensions of the scatterers is determined by obtaining the best filling rate, and finally a One-dimensional phononic crystal beam structure bandgap design, obtain one-dimensional phononic crystal beam str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com