Optical multilayer gradient thin film and preparation device thereof

A technology of optical thin film and gradient film, which is applied in optics, optical components, flat products, etc., can solve the problems of low efficiency and difficulty in ensuring processing accuracy, and achieve simple multi-layer realization, low production cost, and simple design and manufacturing process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

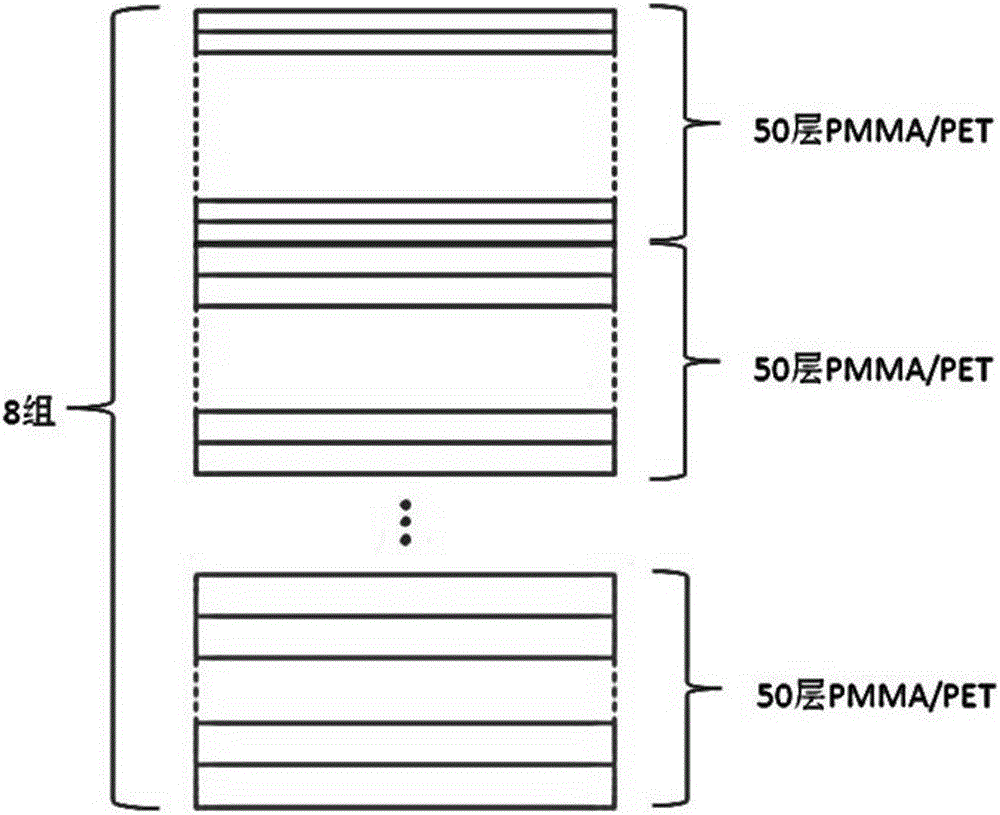

[0022] The present invention proposes an optical multilayer gradient film, in the specific implementation process, such as figure 1 As shown, the optical film is formed by stacking eight groups of unit films, that is, M=4, reflecting two wave bands, and each unit film has polymer materials PMMA and PET alternately forms 50 identical periodic structures, N=50. The first four groups realize high reflection to the ultraviolet band, and the last four groups realize high reflection to the infrared band.

[0023] The unit film satisfies nd=λ / 4, where n is the refractive index of the material, d is the single-layer thickness of the material, and λ is the central wavelength of the unit film.

[0024] In the specific implementation process, if the thickness ratio of the PMMA / PET periodic structure is 1.1, the thickness of the PMMA / PET periodic structure is as follows: the first group is 52.36nm / 47.6nm, the second group is 55.66nm / 50.6nm, and the third group is 58.96nm / 53.6nm, the fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com