Cement-based material forming test die for embedding electrode

A technology of cement-based materials and embedded electrodes, which is used in analytical materials, ceramic molding machines, preparation of samples for testing, etc. Simple structure and high reusability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

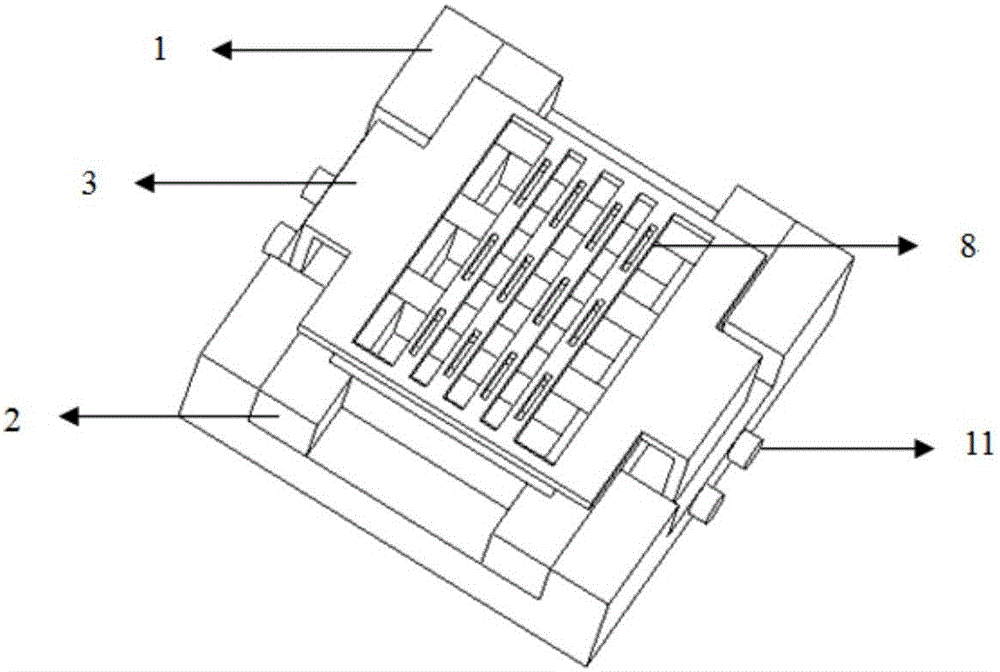

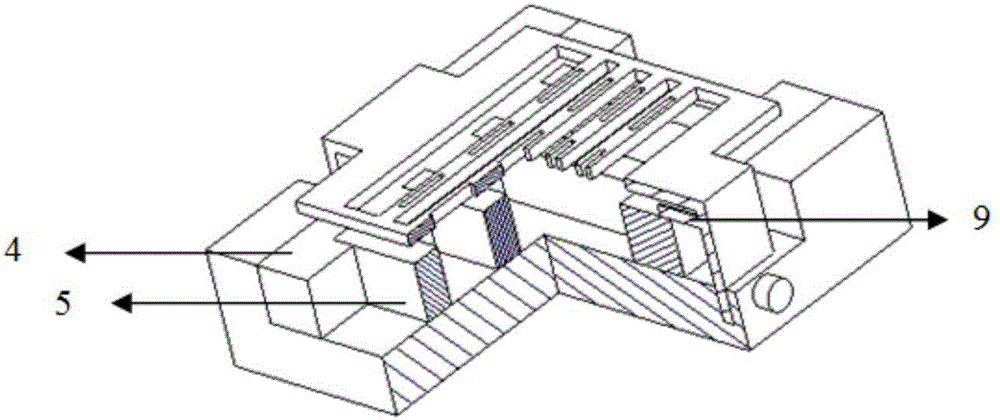

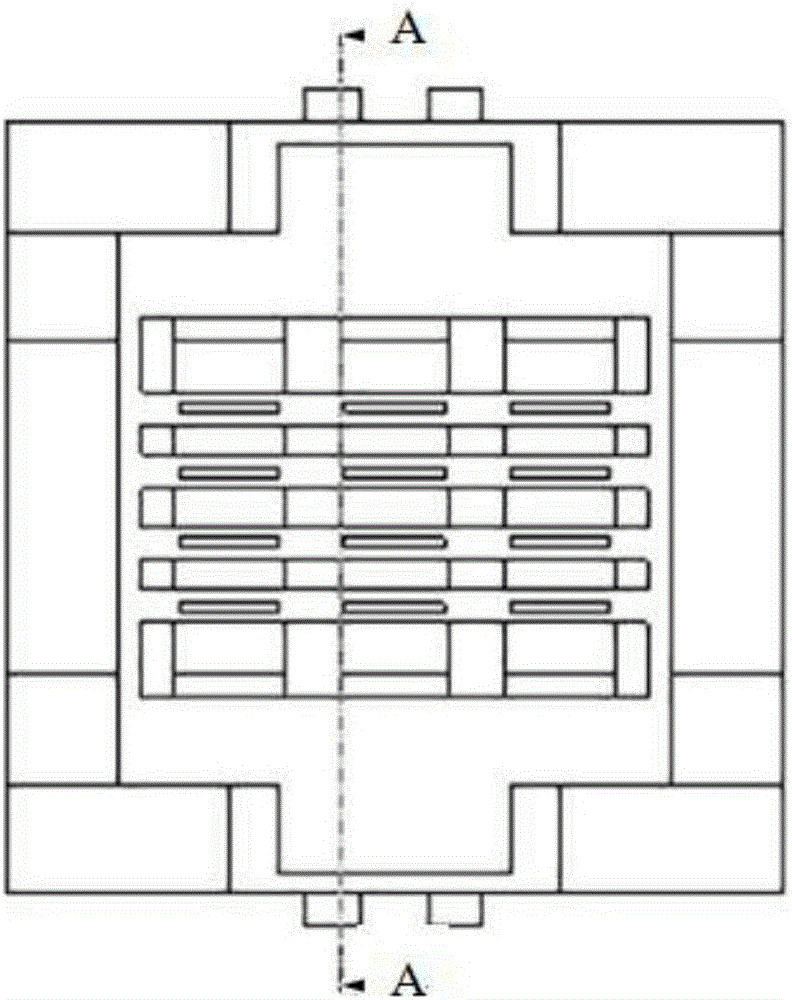

[0020] Such as Figure 1-6 As shown, the cement-based material forming test mold for pre-embedded electrodes of the present invention includes a base 1, a test mold body 2 and a gland 3, and the test mold can use various materials according to needs, such as cast iron or plexiglass Wait.

[0021] The base 1 is composed of a large cube and four small cubes, and the four small cubes are arranged on the four corners above the big cube to form an integral body. There are grooves 6 on both sides of the large cube in the length direction of the base 1, located in the middle of the two small cubes in the length direction of the base 1, the opening direction of the groove 6 is the upper surface of the large cube, the centerline of the groove 6 and the centerline of the base 1 Coinciding, the two grooves 6 have the same size. The tw...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com