Volumetric combustible gas liquefying device utilizing compression-expansion refrigeration and using method thereof

A compression expansion and liquefaction device technology, which is applied in the fields of energy saving and environmental protection, can solve the problems of cumbersome preparation, lower liquefaction efficiency, and influence on the composition of mixed refrigerants, and achieve the effect of reducing air pollution and transportation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

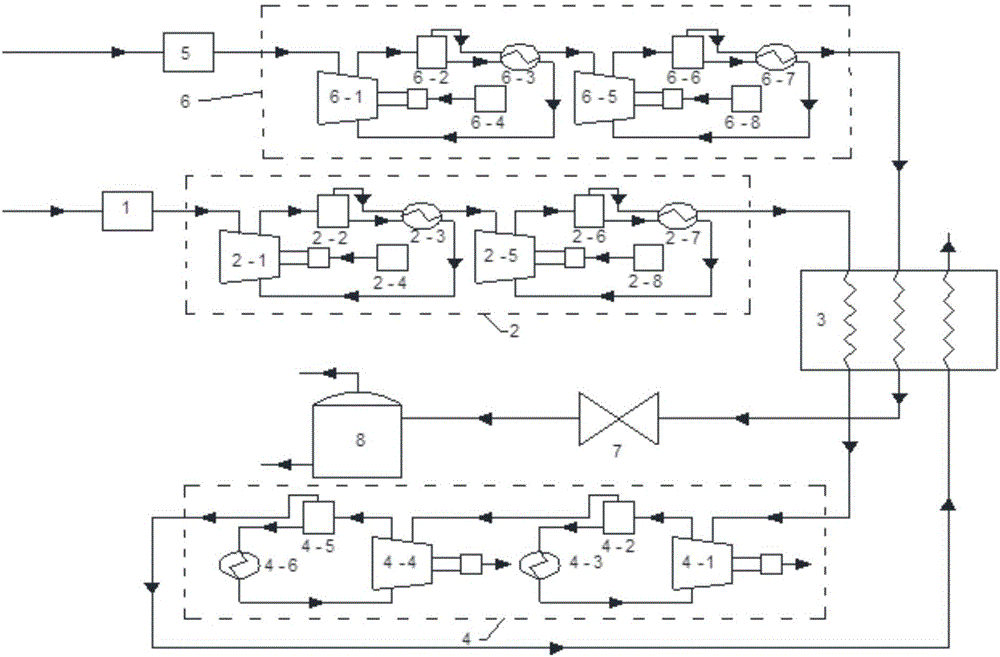

[0064] like figure 1 As shown, the liquefaction device of the present invention is an expansion type liquefaction device with two-stage compression and two-stage expansion of combustible gas; The pretreatment unit 5 removes impurities such as moisture and acid gas in the combustible gas to make it reach the liquefaction standard. The purified combustible gas enters the combustible gas compression unit 6 for compression and cooling. The compression unit is composed of two compressors 6-1 and 6-5. The pinch point temperature difference in the heat exchanger 3, the ambient temperature, and the isentropic efficiency of the expander vary), and then enter the multi-stream heat exchanger 3 for heat exchange, and the temperature drops to -110°C, and then drops through the throttling device 7 When the pressure reaches 2MPa, the combustible gas has been completely liquefied, and finally enters the liquefied combustible gas storage tank 8 for storage and is ready to be shipped.

[0065...

Embodiment 2

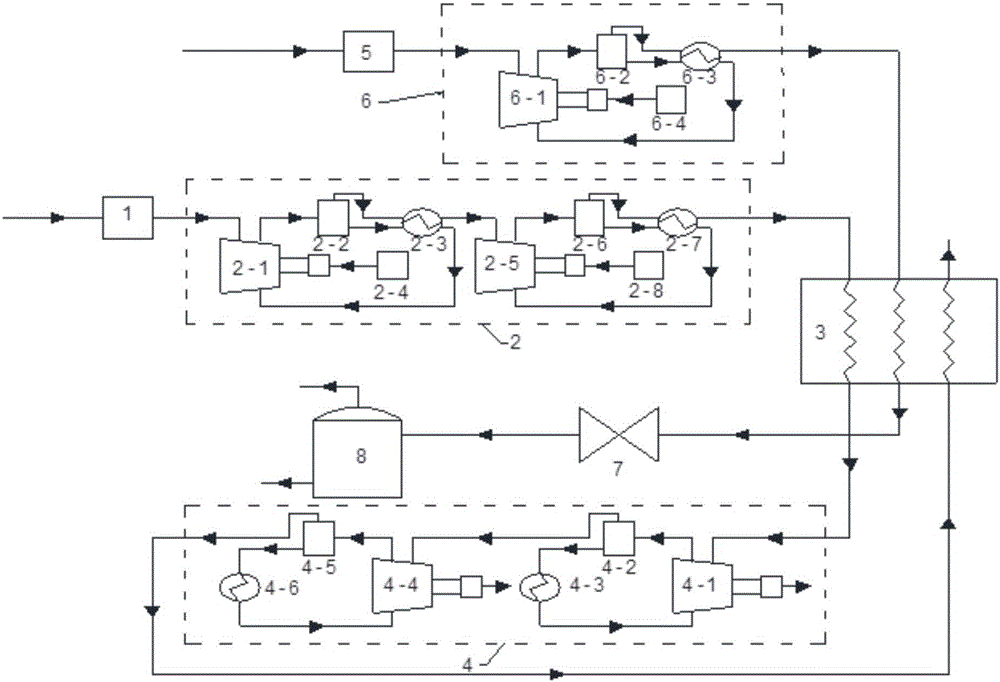

[0068] like figure 2 As shown, the liquefaction device of the present invention is an expansion type liquefaction device with two-stage compression, two-stage expansion, and one-stage compression of combustible gas. 6-1 and 6-5 become one-stage compression 6-1, which is applicable to the situation where the initial pressure of combustible gas is relatively high.

Embodiment 3

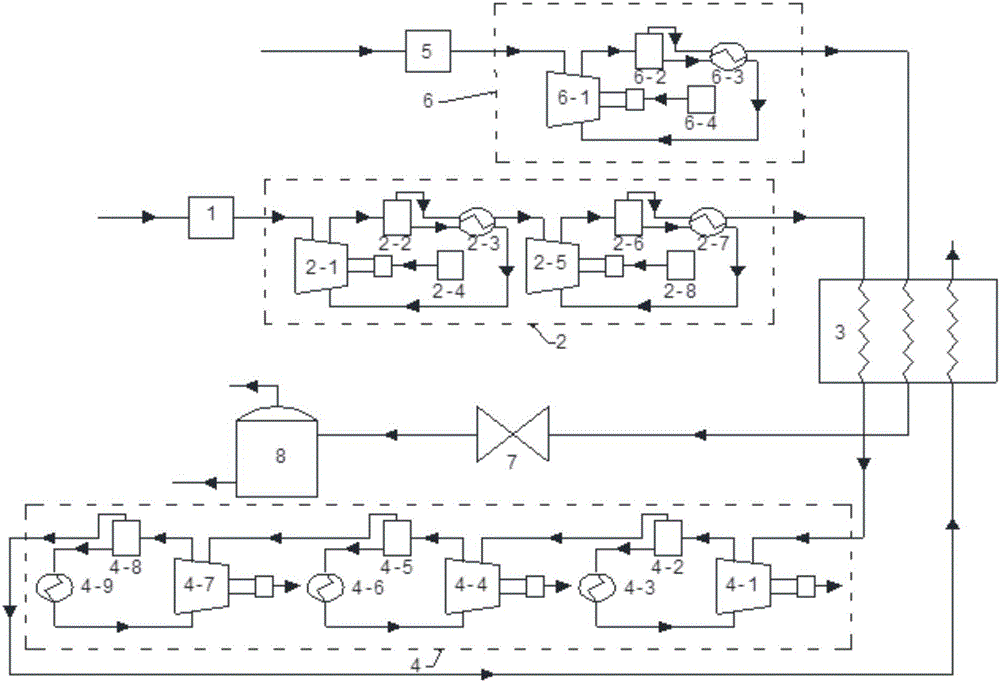

[0070] like image 3 As shown, the liquefaction device of the present invention is an expansion type liquefaction device with two-stage compression and three-stage expansion of combustible gas and one-stage compression. 4-1, 4-4 become three-stage expansion 4-1, 4-4, 4-7, which is applicable to expansion comparison of expanders 4-1, 4-4, 4-7 in refrigerant expansion unit 4 small case.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com