Refined cotton alkali soaking system

A technology of refined cotton and alkali soaking, which is applied in the direction of pulp fat/resin/pitch/wax removal, etc. It can solve the problems of adverse effects, affecting fiber reaction, and unreasonable consideration of impurity removal, etc., so as to improve extrusion efficiency and structural design Reasonable and easy to fully recover the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

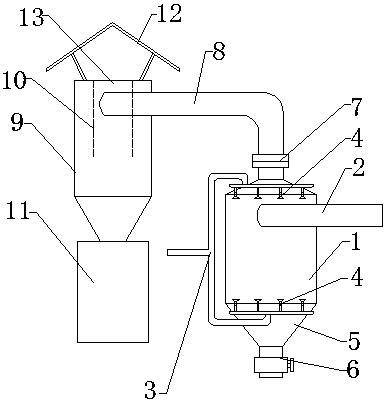

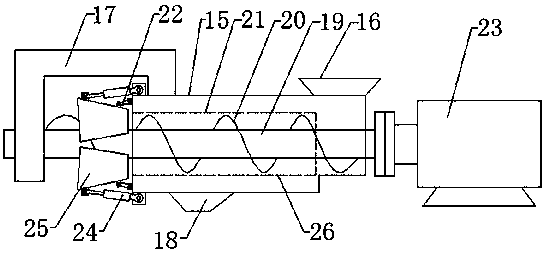

[0012] Refined cotton soaking alkali system, which is mainly composed of a presoaking alkali device and an alkali soaking extrusion device, consisting of figure 1 As shown, the presoaking device mainly includes a presoaking chamber 1, a cyclone 9 and a collection bin 11, one side of the presoaking chamber 1 is provided with a cotton inlet pipe 2, and the raw material cotton linters are passed through the wind The warp inlet pipe 2 enters the presoaking alkali chamber 1, and the other side of the presoaking alkali chamber 1 is provided with a lye inlet pipe 3, and the outlet ends of the lye inlet pipe 3 are respectively placed in the presoaking alkali chamber 1 The top and bottom of the presoaking chamber 1 are connected to one end of the exhaust pipe 8 through the flange structure 7, and the other end of the exhaust pipe 8 is connected to the cyclone 9, and in the cyclone 9 The upper air outlet 13 of the upper air outlet 13 is provided with a cyclone tank 10, the bottom of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com