Aroma enhancement type saccharomyces cerevisiae for raw and cooked materials and preparation method thereof

A technology for brewing wine and aroma type, which is applied in the field of wine making, can solve the problems of insufficient aroma and solidity, weak fat-producing ability, weak aroma of liquor, etc., and achieves complete utilization of raw materials, high wine yield, and increased yeast protein content. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

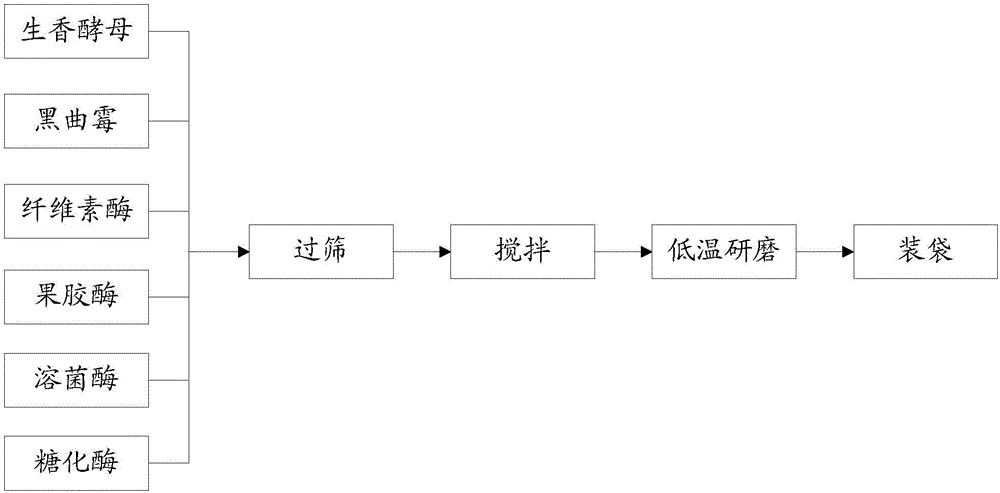

[0024] Such as figure 1 Shown, the step of preparing raw clinker aroma-enhancing type brewing koji comprises:

[0025] Step 1, first according to the mass percentage, obtain 15% aromatic yeast, 25% Aspergillus niger, 25% cellulase, 20% pectinase, 5% lysozyme and 10% glucoamylase, then use 600-mesh sieve for aromatic yeast, 600-mesh sieve for Aspergillus niger, 750-mesh sieve for cellulase, 750-mesh sieve for pectinase, 850-mesh sieve for lysozyme, 600-mesh sieve for lysozyme The screen screens the glucoamylase to remove the impurities; among them, the role of the aroma-producing yeast is to promote the production of ester aroma, the role of Aspergillus niger is to esterify ethanol to produce fat and aroma, and the role of cellulase is to dissolve the crude oil in the starch. Fiber, the function of pectinase is to change the tannin in brewing fruit wine, the function of lysozyme is to eliminate Aspergillus flavus, and the function of glucoamylase is to convert starch into suga...

Embodiment 2

[0031] The steps for preparing raw clinker aroma-enhancing type brewed koji include:

[0032] Step 1, first according to the mass percentage, obtain 15% aromatic yeast, 25% Aspergillus niger, 25% cellulase, 20% pectinase, 5% lysozyme and 10% glucoamylase, then use 550-mesh sieve for aroma yeast, 550-mesh sieve for Aspergillus niger, 700-mesh sieve for cellulase, 700-mesh sieve for pectinase, 800-mesh sieve for lysozyme, 550-mesh sieve for lysozyme The screen screens the glucoamylase to remove the impurities; among them, the role of the aroma-producing yeast is to promote the production of ester aroma, the role of Aspergillus niger is to esterify ethanol to produce fat and aroma, and the role of cellulase is to dissolve the crude oil in the starch. Fiber, the function of pectinase is to change the tannin in brewing fruit wine, the function of lysozyme is to eliminate Aspergillus flavus, and the function of glucoamylase is to convert starch into sugar.

[0033] Step 2. Put the ...

Embodiment 3

[0038] The steps for preparing raw clinker aroma-enhancing type brewed koji include:

[0039] Step 1, first according to the mass percentage, obtain 19% aromatic yeast, 21% Aspergillus niger, 35% cellulase, 15% pectinase, 1% lysozyme and 9% glucoamylase, then use 500-mesh sieve for aromatic yeast, 500-mesh sieve for Aspergillus niger, 650-mesh sieve for cellulase, 650-mesh sieve for pectinase, 800-mesh sieve for lysozyme, 500-mesh sieve for lysozyme The sieve screens the glucoamylase to remove the impurities;

[0040] Step 2. Put the sifted aromatic yeast, Aspergillus niger, cellulase, pectinase, lysozyme, and glucoamylase obtained in step 1 into a mixing tank and stir evenly. The stirring time is 50 minutes and the stirring temperature is 30 degrees. , the rotating speed of stirring tank is 50 revolutions per minute;

[0041] Step 3, put the mixture obtained in step 2 into a low-temperature fine powder mill for low-temperature grinding, the low-temperature grinding temperat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com