Polyurethane internal wall building mildew-proof paint

A polyurethane and anti-mildew technology, applied in polyurea/polyurethane coatings, fireproof coatings, antifouling/underwater coatings, etc., can solve the problems of poor gloss, insufficient water resistance, and poor self-thickening properties of latex films, and achieve long-lasting color , simple maintenance, soft color effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] In the mixer, add 5 parts of water, 10 parts of titanium dioxide, 9 parts of additives (including 1 part of chain extender, 2 parts of leveling agent, 3 parts of dispersant, 1 part of thickener, 0.5 parts of defoamer, 1 part of dustproof agent), 12 parts of filler (ultrafine talc powder: mica powder = 1:1), stir evenly, grind the resulting solution through a sander to a particle size of less than 40 microns, and then put the solution back into the mixer, Dissolve the mixed solvent with the antifungal agent and the leveling agent in the mixed solvent to obtain the antifungal solvent for later use; put the silane adhesion promoter, water-curable polyurethane and water-based acrylic resin into the mixer, and step (2) and ( 3) Mix the solution and anti-mildew solvent in , stir evenly, and you get it.

Embodiment 2

[0055] Add 8 parts of water, 6 parts of titanium dioxide and 13 parts of additives (including 3 parts of chain extender, 2 parts of leveling agent, 1 part of dispersant, 3 parts of thickener, 1.5 parts of defoamer, 2 parts of dust agent), 16 parts of filler (ultrafine talc powder: mica powder = 1:1), stir well, and grind the resulting solution through a sander to a particle size of less than 40 microns, and then put the solution back into the mixer. Dissolve the mixed solvent with the antifungal agent and the leveling agent in the mixed solvent to obtain the antifungal solvent for later use; put the silane adhesion promoter, water-curable polyurethane and water-based acrylic resin into the mixer, and step (2) and (3) ) solution, anti-mold solvent, mixed, stirred evenly, that is.

Embodiment 3

[0057] Add 6 parts of water, 7 parts of titanium dioxide, 8 parts of additives (including 1 part of chain extender, 1 part of leveling agent, 2 parts of dispersant, 1 part of thickener, 1 part of defoamer, 1 part of dustproof agent), 14 parts of filler (ultrafine talc powder: mica powder = 1:1), stir evenly, grind the resulting solution through a sander to a particle size of less than 40 microns, and then put the solution back into the mixer, Dissolve the mixed solvent with the antifungal agent and the leveling agent in the mixed solvent to obtain the antifungal solvent for later use; put the silane adhesion promoter, water-curable polyurethane and water-based acrylic resin into the mixer, and step (2) and ( 3) Mix the solution and anti-mildew solvent in , stir evenly, and you get it.

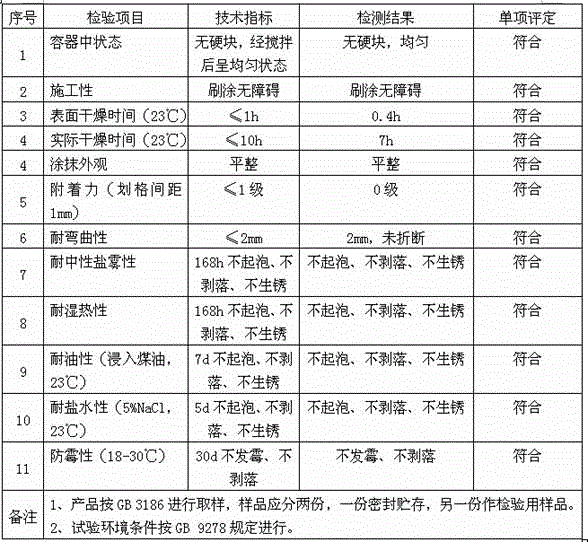

[0058] According to GB / T1723-93, GB / T 1724-89, GB / T 1731-93, GB / T 1732-93, GB / T1733-93, GB / T 1734-93 standards, the results are listed in the table below.

[0059]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com