Stress-whitening-resisting modified styrene-based resin and preparation method thereof

A styrene-based resin and stress-resistant technology, which is applied in the field of stress-whitening-resistant modified styrene-based resin and its preparation, can solve the problems of general internal stress elimination effect, achieve the prevention of stress-whitening phenomenon and high production efficiency , good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] (1) Mix 85 parts of ABS 8434 resin, 15 parts of superfine talc powder (6000 mesh), 0.3 parts of light and heat stabilizer (antioxidant 1076:antioxidant 168=1:2, mass ratio) and 0.1 part of lubricant Stearic acid amide (SR) is mixed evenly by high-speed stirring;

[0043] (2) Send the above mixture into a twin-screw extruder to extrude and granulate to obtain a styrene-based resin;

[0044] In the step (2), the screw temperature of the twin-screw extruder is 400 r / min.

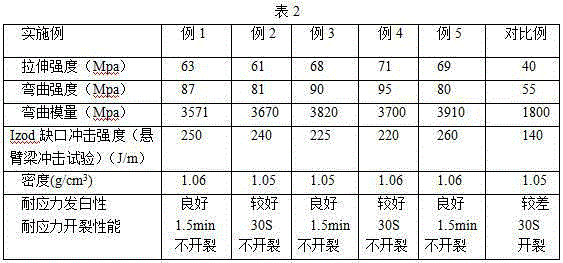

[0045] The prepared compound was injection-molded into a standard sample bar for testing according to the standard size, and the performance test results are shown in Table 2.

Embodiment 2

[0047] (1) Mix 98 parts of ABS8434 and ASA PW-957 resin mixture (ABS8434:ASA PW-957=2:1, mass ratio), 2 parts of superfine talcum powder (7000 mesh), 0.6 parts of light and heat stabilizer (anti- Oxygen agent DLTP: Antioxidant DBTL=1:1, mass ratio) and 0.5 parts of lubricant silicone oil are mixed evenly by high-speed stirring;

[0048] (2) Send the above mixture into a twin-screw extruder to extrude and granulate to obtain a styrene-based resin;

[0049] In the step (2), the screw temperature of the twin-screw extruder is 500 r / min.

[0050] The prepared compound was injection-molded into a standard sample bar for testing according to the standard size, and the performance test results are shown in Table 2.

Embodiment 3

[0052] (1) Mix 90 parts of ASA PW-957 resin, 10 parts of superfine talc powder (6000 mesh), 0.1 part of light and heat stabilizer (DLTP: 2,6-tertiary butyl-4-methylphenol=2:1 , mass ratio) and 1 part of lubricant EBS were mixed evenly by high-speed stirring;

[0053] (2) Send the above mixture into a twin-screw extruder to extrude and granulate to obtain a styrene-based resin;

[0054] In the step (2), the screw temperature of the twin-screw extruder is 300 r / min.

[0055] The prepared compound was injection-molded into a standard sample bar for testing according to the standard size, and the performance test results are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com