A kind of polyquaternium glucose polydimethylsiloxane polyether and its preparation method and handle finishing agent

The technology of polydimethylsiloxane polyether and propyl polydimethylsiloxane is applied in the field of textile functional finishing agents, which can solve the problem of no thermal yellowing and increase the hydrophilicity of polydimethylsiloxane. , the tactile function is not improved, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

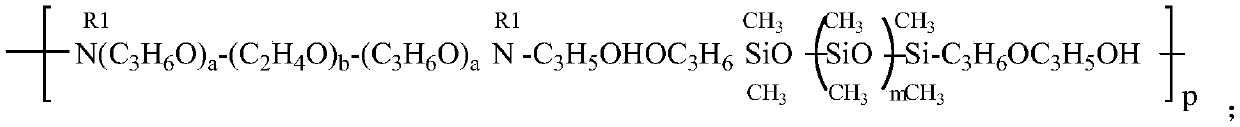

[0071] Embodiment 1. A kind of polyquaternium glucose polydimethylsiloxane polyether

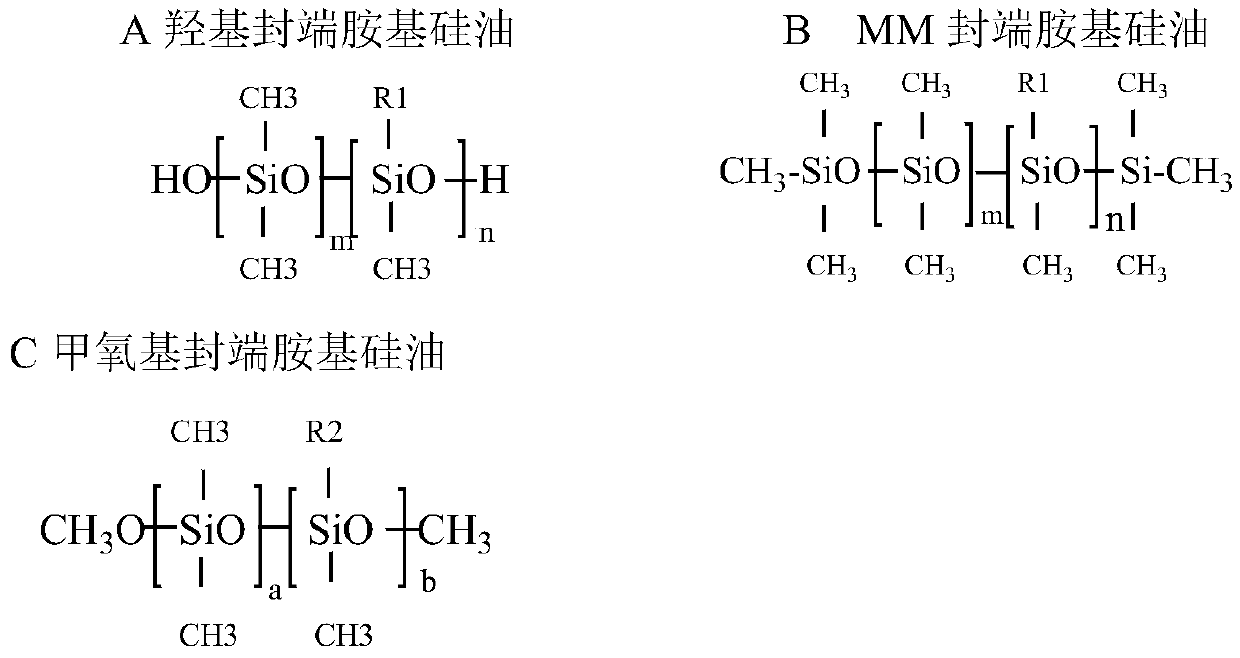

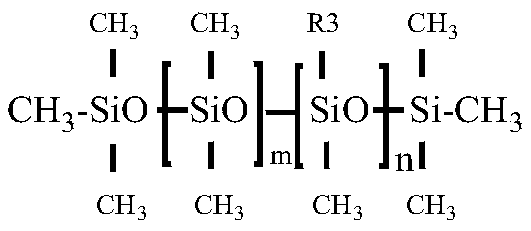

[0072] In this embodiment, a polyquaternium dextrose polydimethylsiloxane polyether is provided. The polyquaternium glucose polydimethylsiloxane polyether is represented by the following general formula I:

[0073]

[0074] Among them, A - from Cl - , Br - , I - , CH 3 COO - , C 2 h 5 COO - , C 3 h 7 COO - or one of laurate; n is an integer selected from 10-1000; a is an integer selected from 1-20; m is an integer selected from 2-100.

[0075] The preparation method of above-mentioned polyquaternium glucose polydimethylsiloxane polyether is specifically as follows:

[0076] Step 1. Starting with 1,1,3,3-tetramethyldihydrodisiloxane and allyl glycidyl ether, the 1,1,3,3-tetramethyldihydrodisiloxane Siloxane and allyl glycidyl ether are mixed according to the molar ratio of 1:(2.1~4.0), and the isopropanol solution with a mass percent concentration of 1% chloroplatinic acid is...

Embodiment 2

[0095] Embodiment 2. A kind of hand finishing agent

[0096] In this embodiment, a hand finishing agent is provided, which comprises: 30-40% of the polyquaternium glucose polydimethylsiloxane polyether prepared in Example 1 by mass percentage; 68 -46% non-ionic emulsifier; 0.01-0.05% acetic acid; the balance is water; and the pH value range of the hand finishing agent is between 4.5-6.5.

[0097] The nonionic emulsifier is isomerized alcohol polyoxyethylene ether, with the following general formula: CH 3 (CHCH 3 )a(CH 2 ) b O(C 2 h 4 O) c H represents; Wherein, a=1~4, b=1~10, c=3~20. Preferably, the nonionic emulsifier is selected from one or more mixtures of isomeric C8 alcohol polyoxyethylene ethers, isomeric C10 alcohol polyoxyethylene ethers or isomeric C13 alcohol polyoxyethylene ethers.

[0098] The preparation method of the above-mentioned hand finishing agent is specifically as follows.

[0099] Mix the polyquaternium glucose polydimethylsiloxane polyether obt...

Embodiment 3

[0100] Embodiment 3. The performance test of the handle finishing agent described in embodiment 2

[0101] In this example, the film-forming performance of the hand finishing agent obtained in Example 2 was studied.

[0102] The applicant found that the tactile style of "dry, natural, fine and skin-friendly, and silky smooth" mainly comes from the introduction of glucosamine chain links into the molecular structure of the polymer, which has a strong independent film-forming ability at room temperature. In the polymer polyquaternium glucose isohydroxypropyloxypropyl polydimethylsiloxane polyether molecule, two adjacent polyquaternium glucose chains form a very orderly, dense and very smooth surface after dehydration at high temperature The solid film has a very unique tactile smoothness.

[0103] Therefore, in this example, the final film-forming properties of different types of silicone oils were observed and studied by baking the film prepared from the product emulsion on a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com