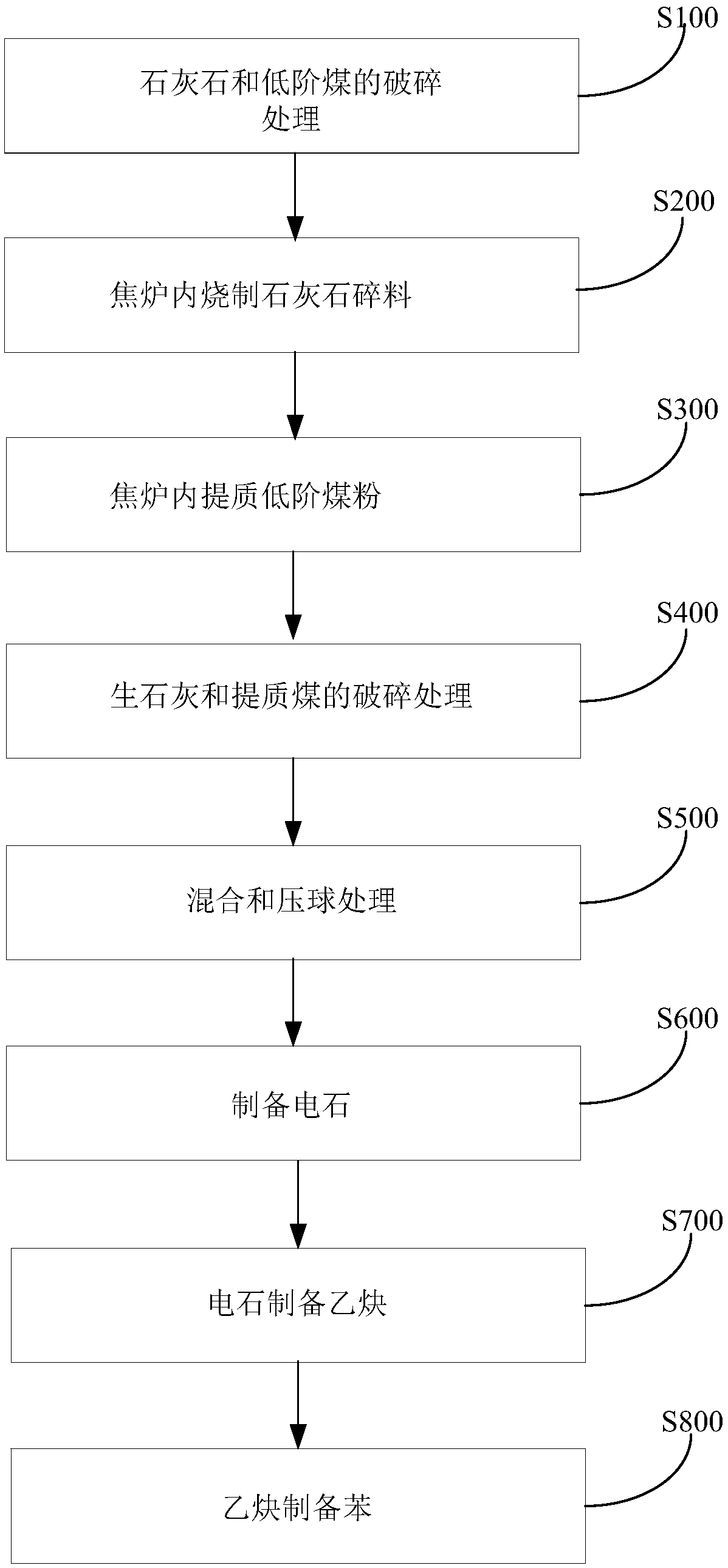

Method and system for preparing benzene from low-rank coal

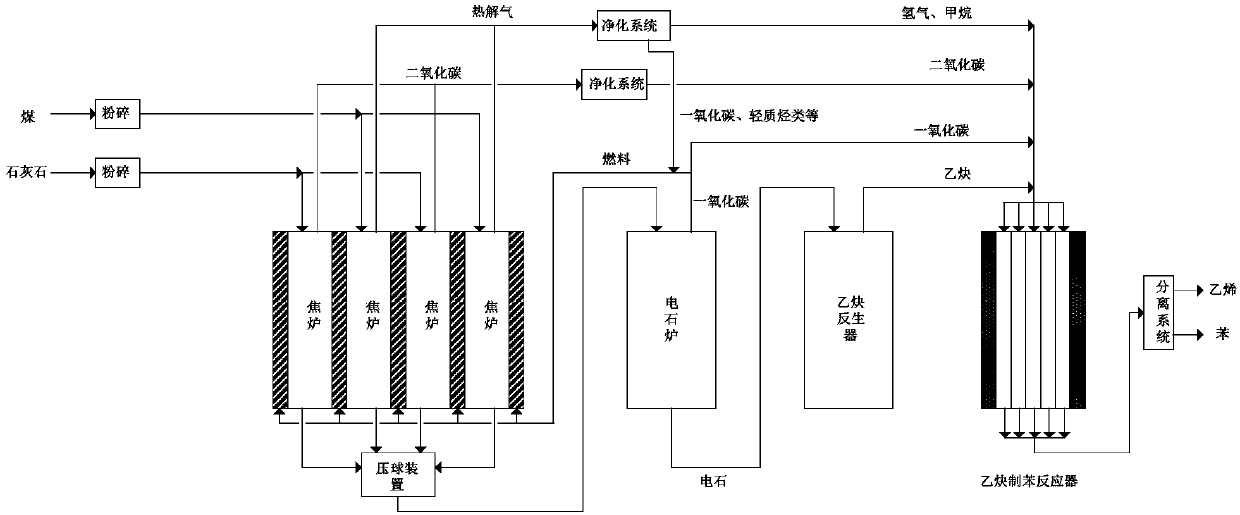

A technology for low-rank coal and upgraded coal, applied in the field of metallurgy, can solve the problems of inability to fully utilize resource value, low direct combustion or gasification efficiency, and high water content of low-rank coal, achieving low processing difficulty, clean and efficient utilization, The effect of increasing production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

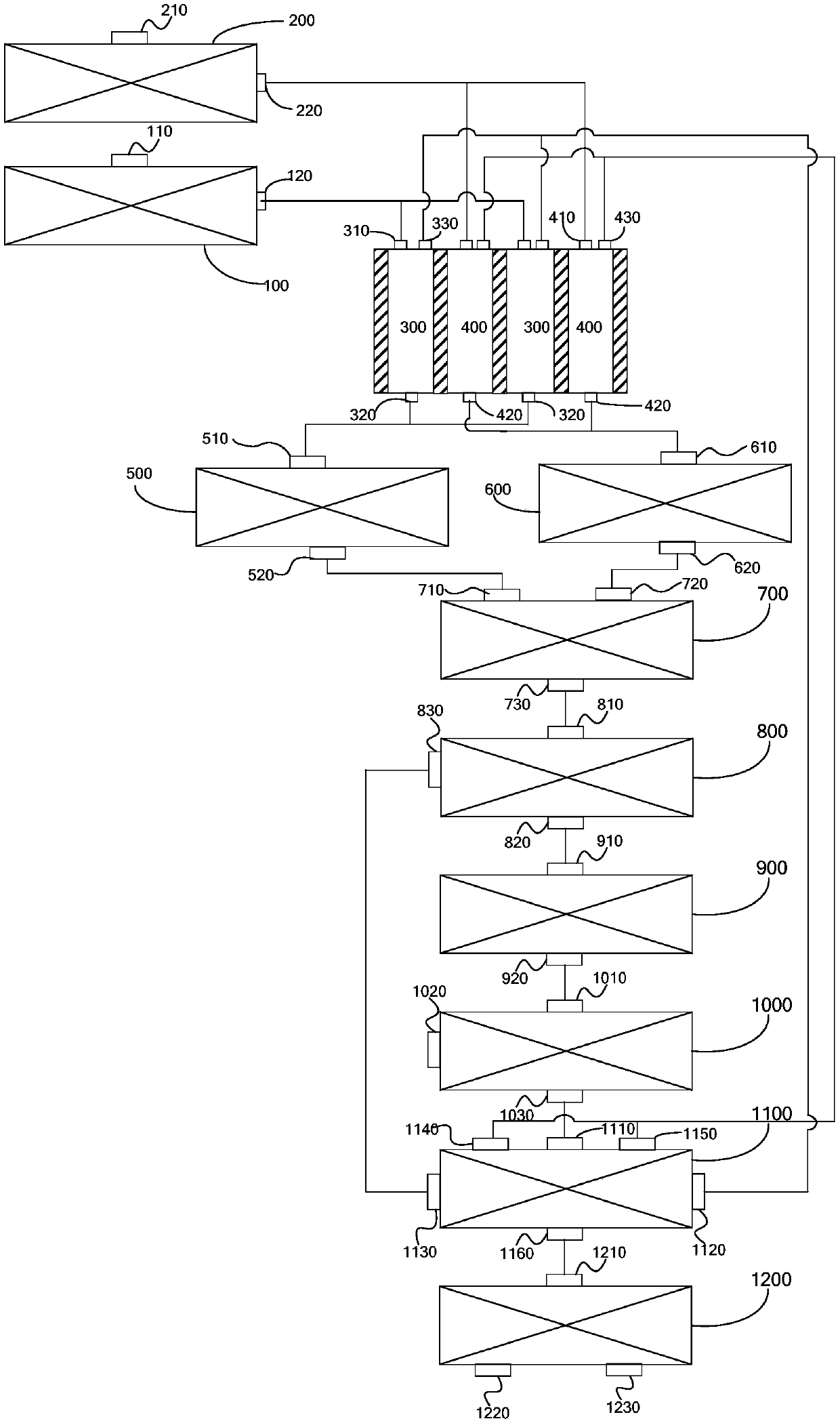

[0146] Crush the limestone to less than 45mm, choose a particle size of 5-45mm, and transport it to the coke oven for firing by belt. The medium and low-rank coal is crushed to below 25mm, and the particle size is selected to be 5-25mm, and it is transported to the coke oven for pyrolysis through the belt. The mass ratio of medium and low rank coal to limestone is 1:2, and the heating temperature of the coke oven combustion chamber is 1000°C. After 12 hours of firing and pyrolysis, the upgraded coal and quicklime are pulverized until the particle size is less than 20 μm. The mixed material enters the ball pressing device for molding, and the formed pellets are put into the high-level trough of the calcium carbide production system, and then put Calcium carbide furnace produces calcium carbide. The calcium carbide produced is cooled and pulverized, and the particle size of the calcium carbide is controlled between 50 and 80 mm, and then enters the acetylene generator to react ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com