Coal mine early strength type low-cost filling material and preparation method thereof

A filling material, early-strength type technology, applied in coal mine early-strength low-cost filling material and its preparation, in the field of coal mine filling materials, can solve the problem of high cost of coal mine filling materials, and achieve low cost, high early strength and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

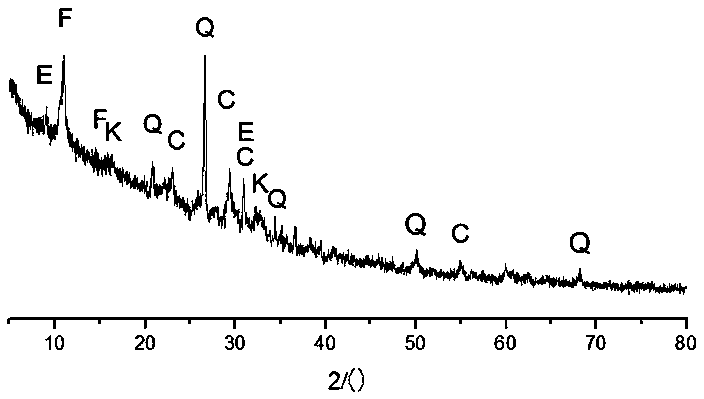

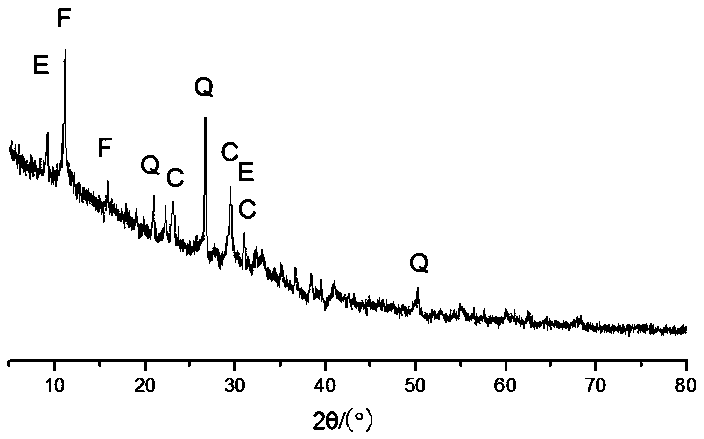

Image

Examples

Embodiment 1

[0049] In Example 1, Example 2, and Example 3, the coal gangue for excavation was all taken from the gangue hill of Lugou Coal Mine of Zhengzhou Coal Group, mainly sandstone coal gangue and limestone coal gangue, and its chemical composition is shown in Table 1. The bottom ash was taken from Zhengzhou Coal Group Dongfeng Power Plant, and its chemical composition is shown in Table 2.

[0050] Table 1 Main chemical composition of coal gangue excavated in Lugou Mine (unit %)

[0051] type SiO 2

al 2 o 3

CaO Fe 2 o 3

MgO Sandstone coal gangue 83.57 1.28 6.62 1.12 0.02 limestone coal gangue 18.34 2.51 59.33 5.24 3.40

[0052] Table 2 Bottom ash chemical composition (unit %)

[0053] SiO 2

Al 2 o 3

Fe 2 o 3

CaO MgO SO 3

TiO MnO 49.36 27.11 11.48 5.41 2.13 1.01 0.77 0.04

[0054] The Portland cement clinker in the cement was obtained from Zhengzhou Longli Cement Pl...

Embodiment 2

[0074] Put the sulphoaluminate cement clinker and Portland cement clinker into the ball mill to grind for 45 minutes, so that the specific surface area of the powder reaches 400m 2 / kg. Put the dry fly ash into the ball mill and grind for 15 minutes until the specific surface area of the powder reaches 400m 2 / kg, put the water-quenched slag into the ball mill and grind for 45min until the specific surface area of the powder reaches 350m 2 / kg, put the desulfurized gypsum into the ball mill and grind for 35min until the specific surface area of the powder reaches 360m 2 / kg.

[0075] Mix the ground dry fly ash, water-quenched slag, and Portland cement clinker according to the mass ratio of 2:1:1. The total mass of the three accounts for 15.4% of the filling material, and add the ground sulfur aluminum Salt cement clinker and desulfurized gypsum are mixed evenly again, and the mass ratio of sulphoaluminate cement clinker to desulfurized gypsum is 1:1, and the sum of ...

Embodiment 3

[0080] Put the sulphoaluminate cement clinker and Portland cement clinker into the ball mill to grind for 38 minutes, so that the specific surface area of the powder reaches 380m 2 / kg. Put the dry fly ash into the ball mill and grind for 19 minutes until the specific surface area of the powder reaches 425m 2 / kg, put the water-quenched slag into the ball mill and grind for 50min until the specific surface area of the powder reaches 380m 2 / kg, put the desulfurized gypsum into the ball mill and grind for 30min until the specific surface area of the powder reaches 340m 2 / kg.

[0081] Mix the ground dry fly ash, water-quenched slag, and Portland cement clinker according to the mass ratio of 2:1:1. The total mass of the three accounts for 15.4% of the filling material, and add the ground sulfur aluminum Salt cement clinker and desulfurized gypsum are mixed evenly again, and the mass ratio of sulphoaluminate cement clinker to desulfurized gypsum is 1:1, and the sum of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com