Water body purification gallery and technology used for river channel water body ammonia nitrogen in situ treatment

A water purification and in-situ treatment technology, which is applied in biological water/sewage treatment, water/sludge/sewage treatment, polluted waterways/lakes/ponds/rivers treatment, etc., which can solve the problem of large footprint and high investment , cumbersome operation and maintenance, etc., to achieve fast start-up speed, high oxygen mass transfer rate, and good effect of dissolved oxygen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

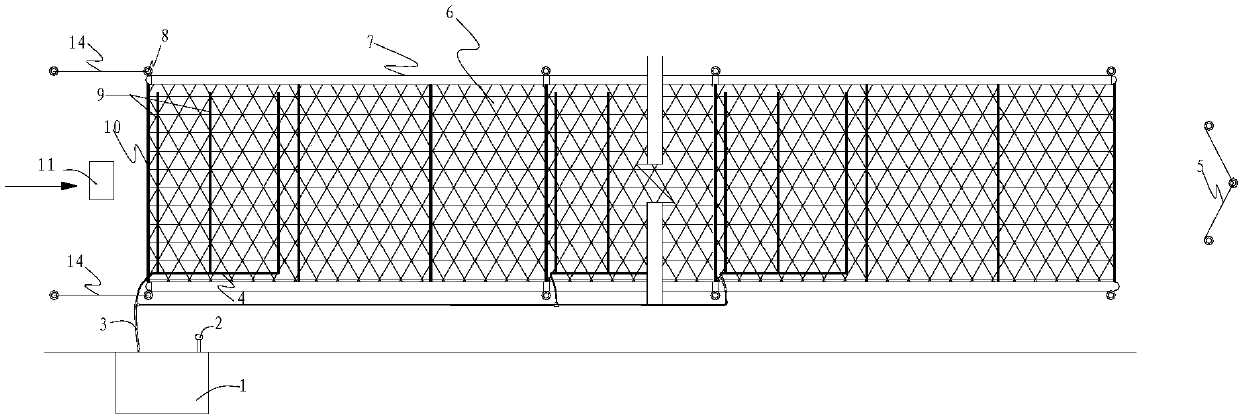

[0080] A 100-meter-long experimental river section was selected in Zheshan Port, Yuhang District, Hangzhou City. Zheshan Port has a total length of 7.08 kilometers, a river surface width of 15-30 meters, and a current water level of 2.4 meters. The water quality is inferior to Class V water bodies.

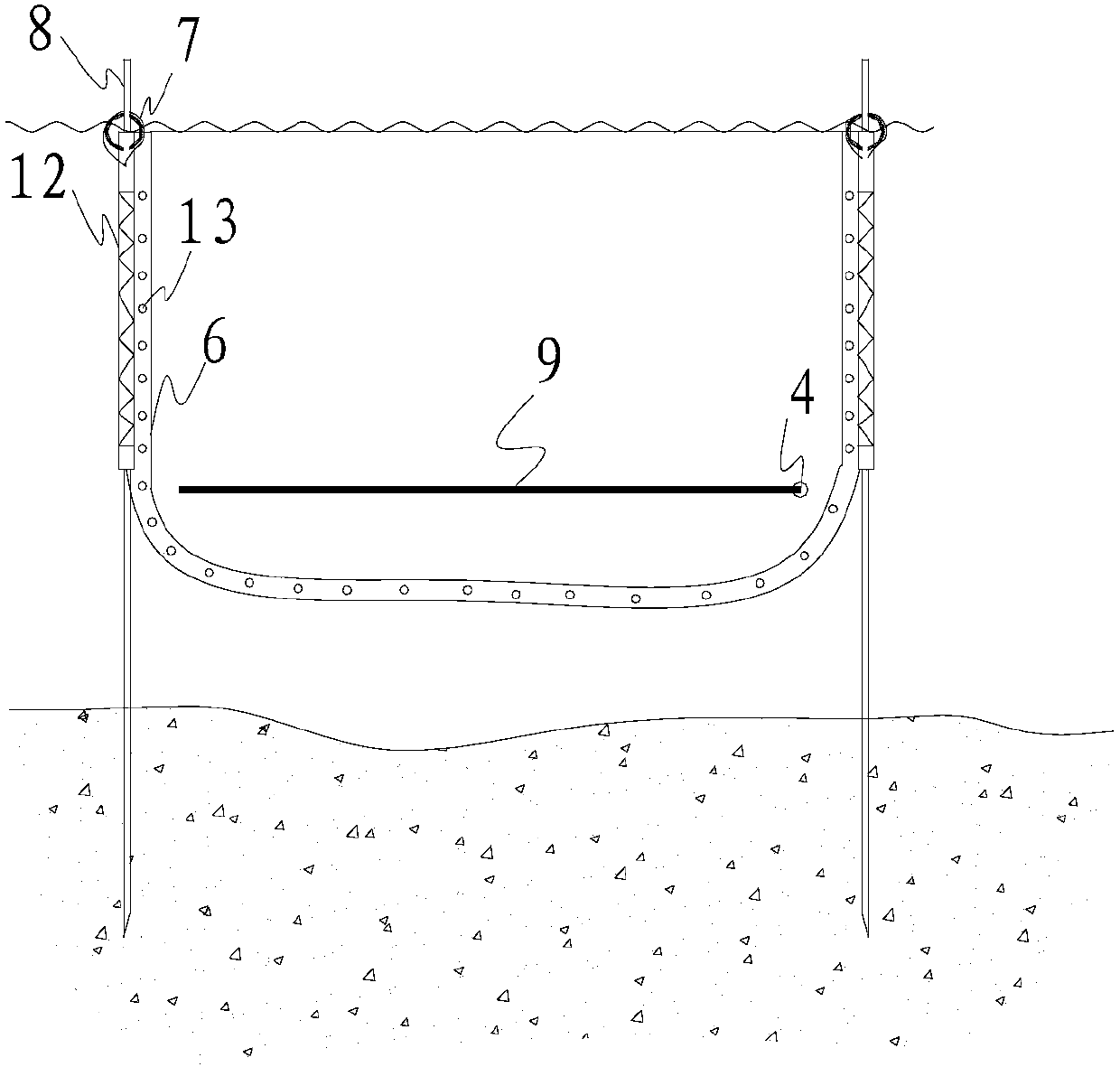

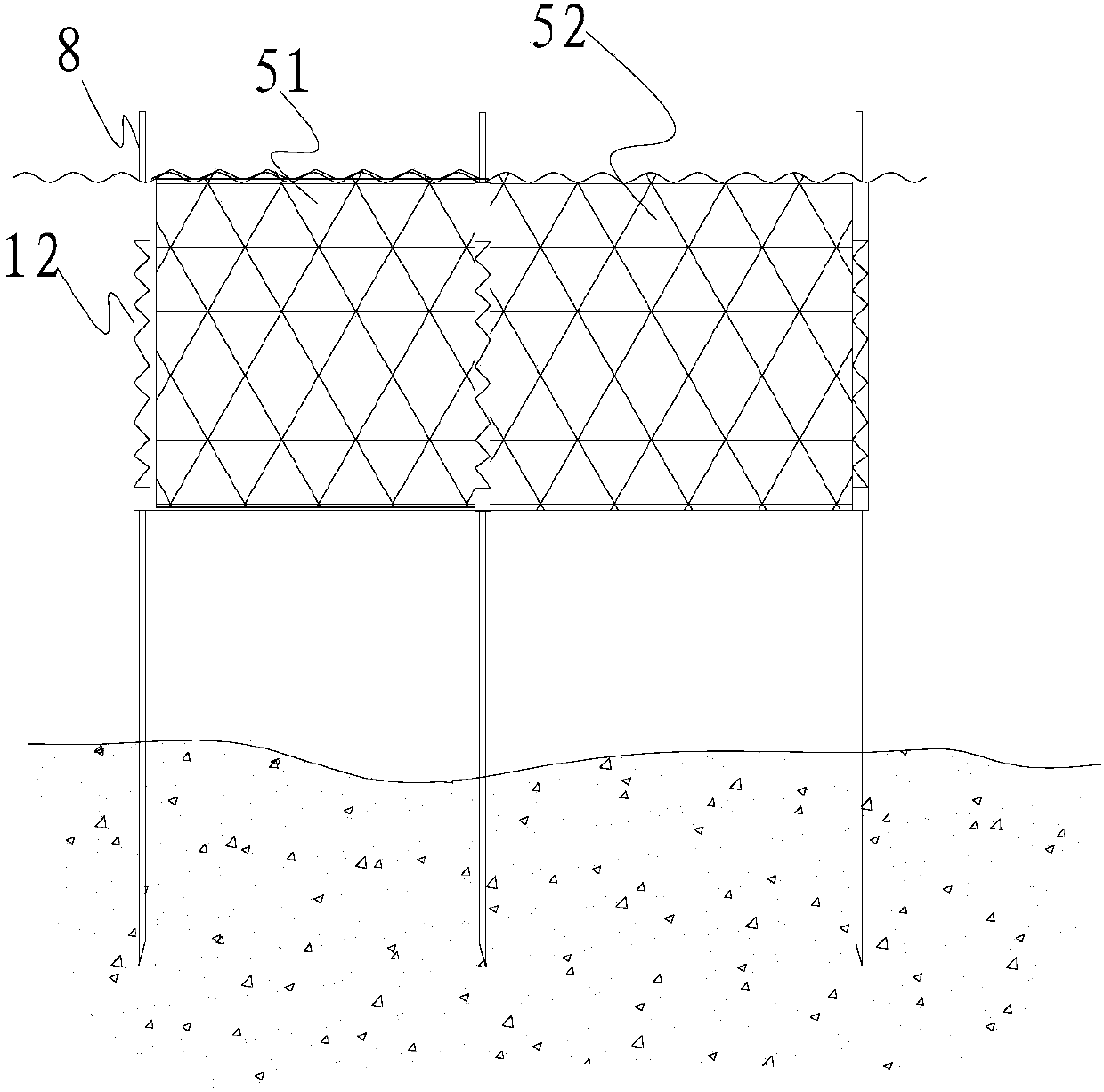

[0081] The water body purification corridor of the present invention is installed in the wide waters of Zheshan Port. The whole is 5 grades of corridors connected in series, and the polyurethane and bamboo ball fillers with successful film formation are put into the corridors. The corridor as a whole is suspended above the bottom mud of the polluted river body, and the lowest point of the corridor bottom is 1 meter underwater.

[0082] Zheshan Port is a flowing water body, and the flow rate is limited to 0.01m / s by operating the flow control valve. Turn on the nano-bubble machine to generate oxygen-enriched water with a pore size of 300 mm, which is sent from the outlet pipe to t...

Embodiment 2

[0090] A 60-meter-long test river section was selected in Jijiaba Port, Renhe Street, Yuhang District, Hangzhou City. The total length of Jijiaba Port is 940m, the width is about 10-15m, the average water depth is 1m, the water surface area of the river is about 10,000 square meters, and the water quality is inferior to Class V water body.

[0091] The water purification corridor of the present invention is installed in the wide waters of Jijiaba Port. The overall corridor is a 3-stage series connection, and the polyurethane and bamboo ball fillers that have been successfully filmed are put into the corridor. The corridor as a whole is suspended above the bottom mud of the polluted river body, and the lowest point of the corridor bottom is 0.8 meters underwater. The deflector is set at 120°, 3 meters from the last corridor.

[0092] The port of Jijiaba is the Duantou River, equipped with a 0.9kW.h thruster. Turn on the nano-bubble machine to generate oxygen-enriched water ...

Embodiment 3

[0100] A test river section with a length of 80 meters was selected in Mujiaba Port, Renhe Street, Yuhang District, Hangzhou City. The east-west direction of Mujiaba Port is about 759m long, 5-10m wide (average width is about 7m), and the average water depth is 1m. The water depth is 1m, and the total water surface area of the river is about 12000m 2 .

[0101] Install a water purification corridor in the "7"-shaped tributary of Mujiaba Port. The overall corridor is a 4-level series connection, and the polyurethane and bamboo ball fillers that have been successfully filmed are placed in the corridor. The corridor as a whole is suspended above the bottom mud of the polluted river body, and the lowest point of the corridor bottom is 1 meter underwater. The deflector is set at 150°, 3.5 meters away from the last corridor.

[0102] Mujiaba Port is the Duantou River, equipped with a 1.2kW.h thruster. Turn on the nano-bubble machine to generate oxygen-enriched water with a por...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com