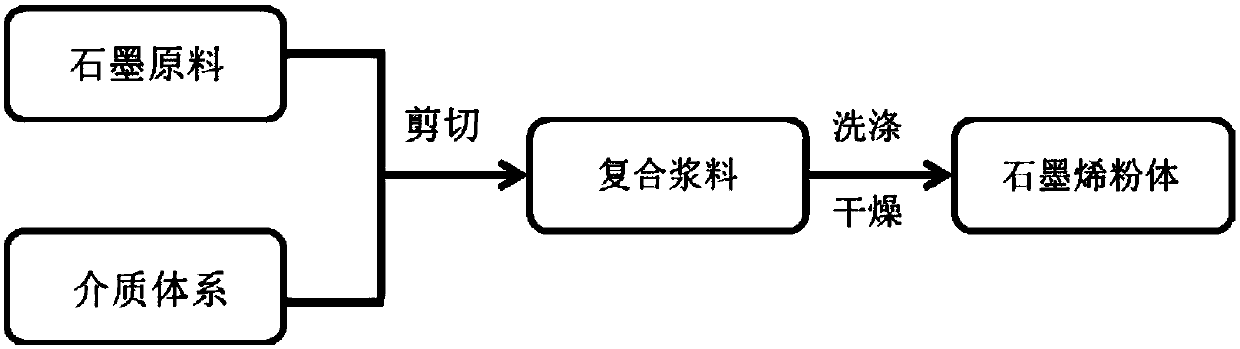

Method for preparing graphene from graphite through HPLC (high performance liquid chromatography) stripping

A liquid-phase exfoliation and graphene technology, applied in the field of nanomaterials, can solve problems such as low efficiency, achieve the effect of improving the exfoliation efficiency and enhancing the effect of mechanical exfoliation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] A large-scale technical method for preparing graphene based on viscosity-enhanced exfoliated graphite, realized by the following scheme: first weigh 50g polyvinyl chloride (PVC) and dissolve it in 100mL N-methylpyrrolidone (NMP) to form a uniform and viscous medium system , The viscosity of the medium system is controlled at around 8000cP. Then, weigh 3 g of expanded graphite and add it to the prepared medium system, and manually stir and mix evenly to form a mixture. The mixture was put into a 250mL temperature-controllable jacketed beaker, and then sheared at a speed of 5000 rpm for 2 hours with a shear disperser to achieve graphite exfoliation. Pour out the sheared composite slurry again, add a large amount of organic solvent N-methylpyrrolidone (NMP) identical to the above steps to dilute until the black aggregates in the composite slurry are completely dispersed, and then stand overnight. Centrifuge and wash at 5000 rpm for 10 minutes to remove the polymerized pol...

Embodiment 2

[0057] A technical method for large-scale preparation of graphene based on viscosity-enhanced exfoliated graphite, realized by the following scheme: first weigh 26g of polyethylene (PE) and dissolve it in 100mL of dimethylformamide (DMF) to form a uniform and viscous medium system , The viscosity of the medium system is controlled at about 1000cP. Then, weigh 1 g of expandable graphite and add it to the prepared medium system, and manually stir and mix evenly to form a mixture. The mixture was put into a 250 mL temperature-controllable jacketed beaker, and then sheared with a shear disperser at a speed of 4000 rpm for 2.5 hours to achieve graphite exfoliation. Pour out the sheared composite slurry again, add a large amount of organic solvent dimethylformamide (DMF) identical to the above steps to dilute until the black aggregates in the composite slurry are completely dispersed, and then stand overnight, After centrifuging and washing at 4000 rpm for 15 minutes, polymerized p...

Embodiment 3

[0059] A large-scale technical method for preparing graphene based on viscosity-enhanced exfoliated graphite is realized by the following scheme: first weigh 80g nylon (PA) and dissolve it in 100mL formamide to form a uniform and viscous medium system, and the viscosity of the medium system is controlled at About 50000cP. Then, weigh 0.5 g of 325-mesh flake graphite and add it to the prepared medium system, and manually stir and mix evenly to form a mixture. The mixture was put into a 250mL temperature-controllable jacketed beaker, and then sheared at a speed of 3000 rpm for 3 hours with a shear disperser to achieve exfoliation of graphite. Then pour out the sheared composite slurry, add a large amount of organic solvent formamide same as the above steps to dilute until the black aggregates in the composite slurry are completely dispersed, then let stand overnight, and centrifuge at 3000 rpm After washing for 30 minutes, the polymerized polymer was removed, and the upper laye...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com