A rotary razor blade and a razor head provided with the blade

A razor and rotary technology, applied in the field of razor heads and rotary razor blades, can solve the problems of increased self-weight, easy deformation, increased current, etc., to improve the sharpness, rigidity and strength of the blade Strengthen and reduce the effect of working current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

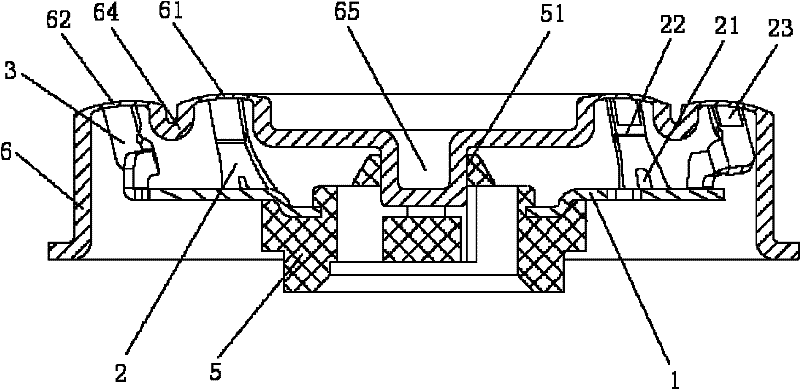

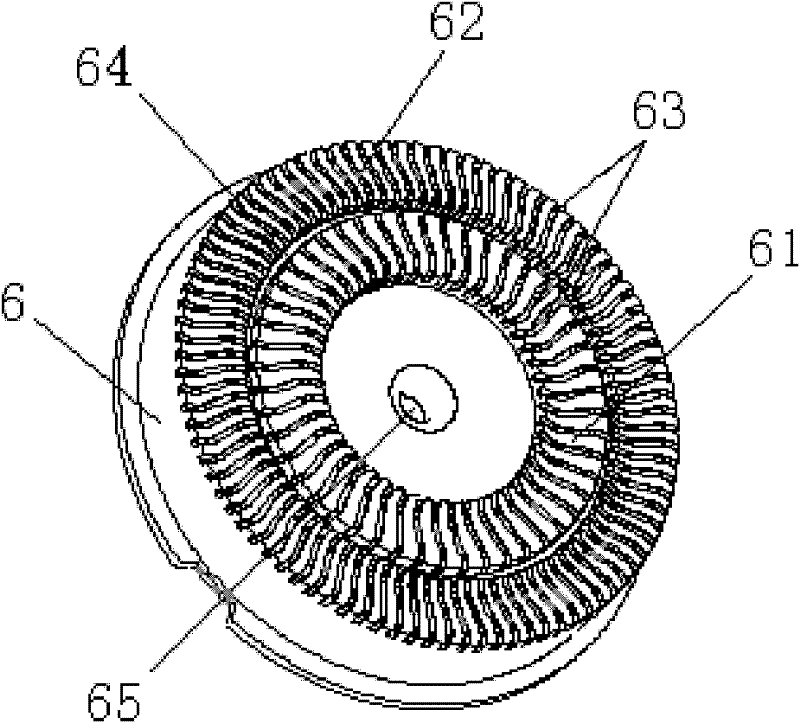

[0022] like Figures 1 to 3 A structural schematic view of an embodiment of the present invention is shown, a rotary razor blade, including a blade body 1 and an inner cutter ring on the blade body, the inner cutter ring includes at least one inner ring cutter 2, and the inner ring cutter is vertical The radial direction of the blade body and the head of the inner ring cutter are inclined upward. The blade body has a groove 11 formed after the inner ring cutter is set. The inner ring cutter is provided with a strengthening structure that strengthens the connection strength of the inner ring cutter, so A stress release structure for avoiding stress concentration on the blade body is provided in the groove.

[0023] The strengthening structure includes a bag 21 arranged at the root of the inner ring cutter and protruding upward relative to the upper surface of the inner ring cutter, and the bag extends to the blade body; the strengthening structure also includes a bending sectio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com