Rotary hearth furnace

A technology of rotary hearth furnace and annular furnace, which is applied in the direction of phosphoric acid, phosphorus oxyacid, and phosphate material treatment. The effect of reducing power consumption and improving energy efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

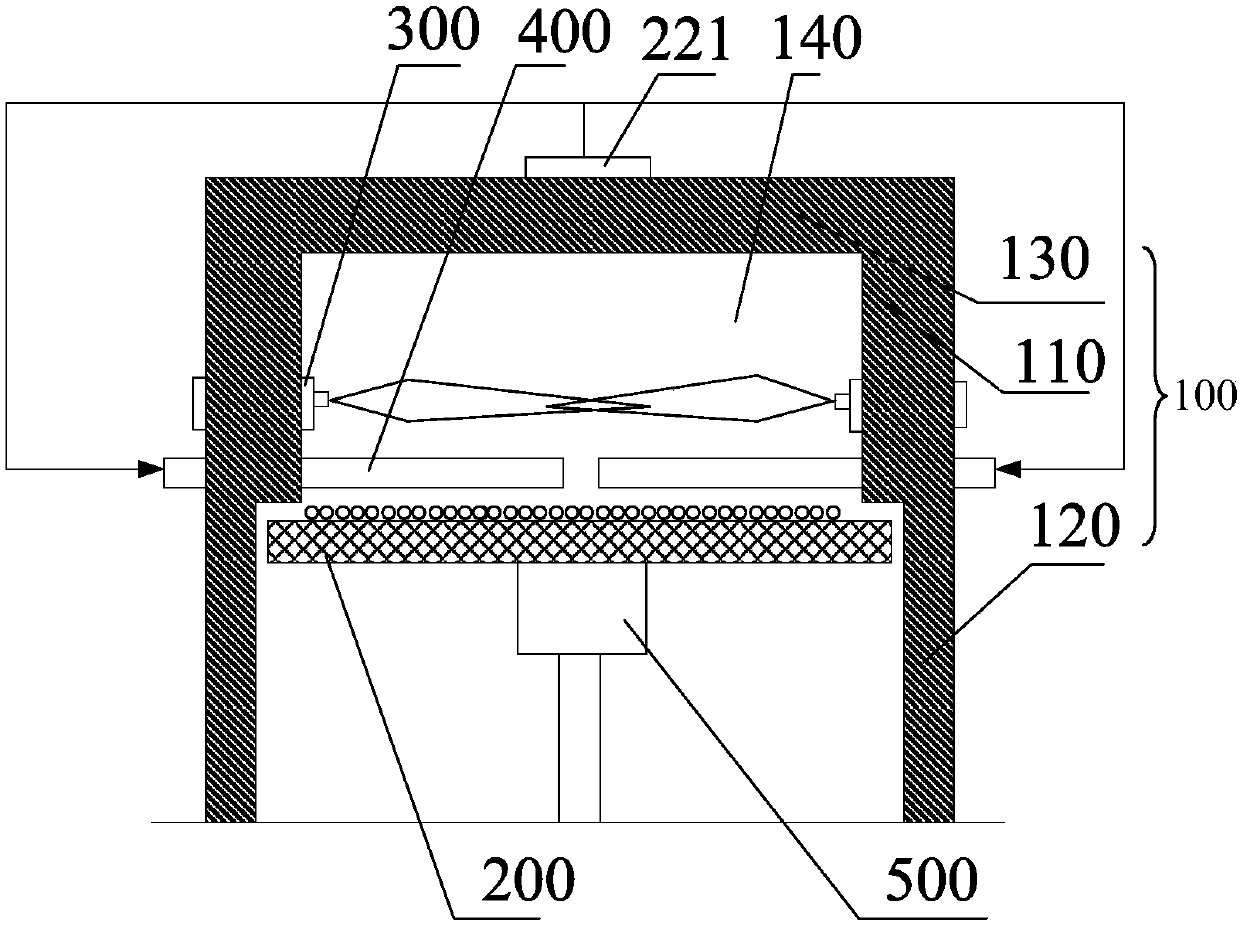

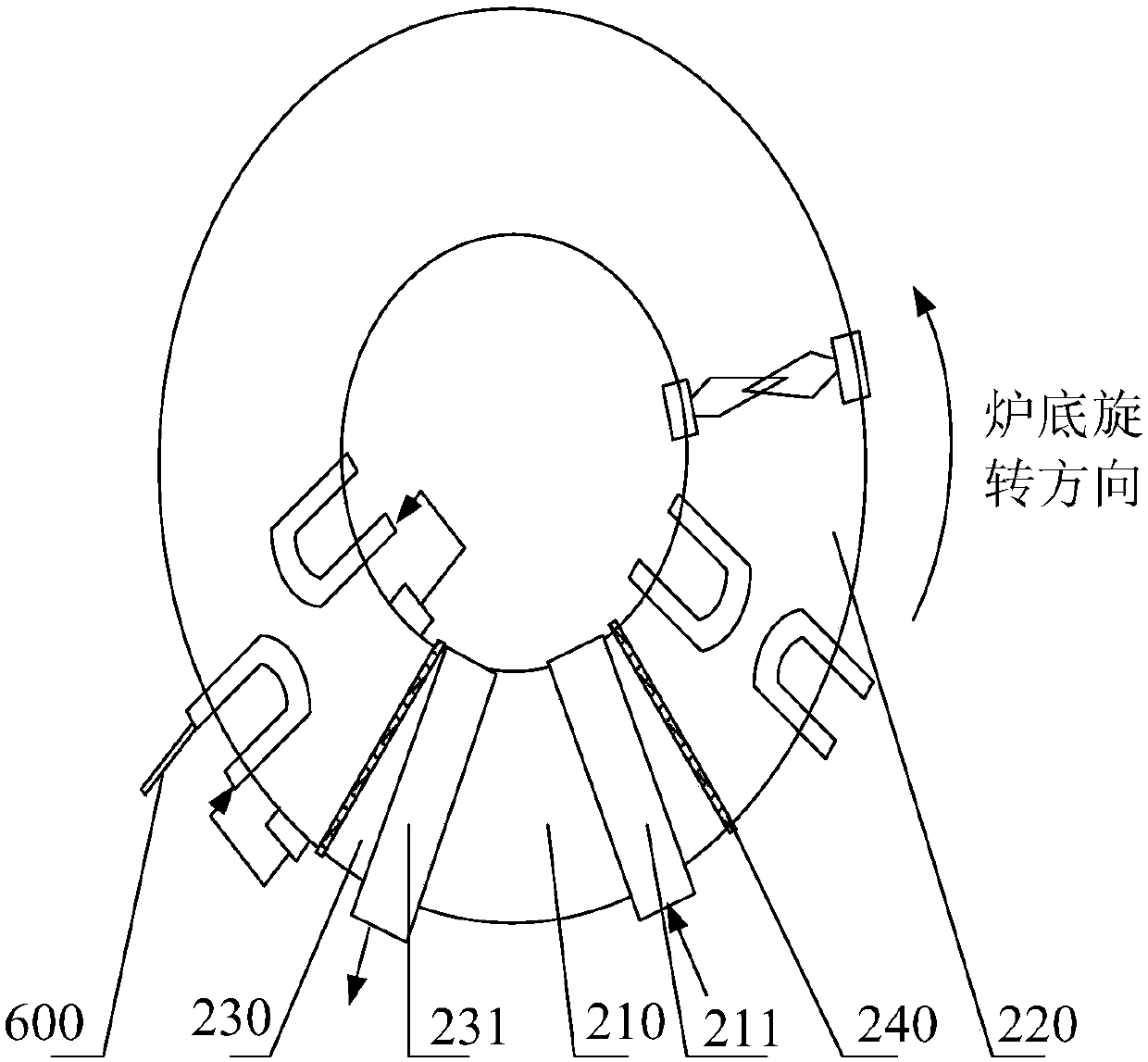

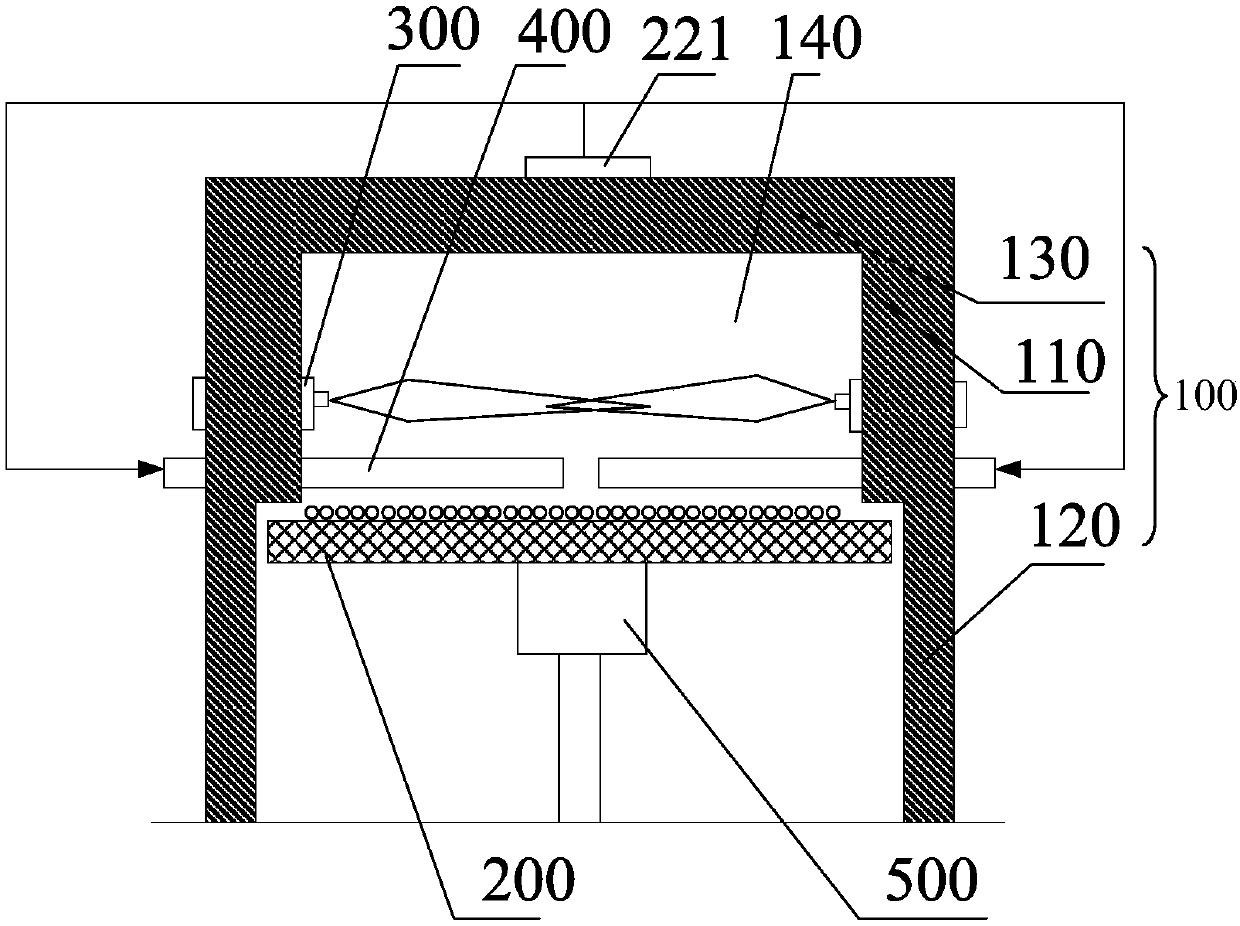

[0061] The rotary hearth furnace of the embodiment of the present invention is used to process phosphate rock to prepare phosphoric acid. The specific method is as follows: the phosphate rock that is ground to 200 mesh and accounts for more than 60% is mixed evenly with semi-coke, silica and binder according to a certain proportion, and made with a disc. Ball machine pelletizing, where P 2 o 5 The grade is 22%, the amount of semi-coke added is 1.1 times of the theoretical requirement, the amount of silica added is 11% of the weight of phosphate rock, the binder is selected from sodium-based raw materials and bentonite, and then the grate is used at 100-200 ° C The prepared carbon-containing pellets are dried until the water content is less than 1%. The dried carbon-containing pellets are placed in a rotary hearth furnace for preheating and reduction. The reaction section of the rotary hearth furnace maintains a reducing atmosphere. The reduction temperature is 1300°C. The spe...

Embodiment 2

[0063] Utilize the rotary hearth furnace of the embodiment of the present invention to process phosphate rock to prepare phosphoric acid. The specific method is as follows: mix the phosphate rock crushed to -2mm and account for more than 90% with lignite, silica and binder according to a certain proportion and press the ball with a briquetting machine. , where P 2 o 5 The grade is 28%, the amount of lignite added is 1.3 times of the theoretical requirement, the amount of silica added is 3% of the weight of phosphate rock, the binder is liquid binder, and the pressed pellets are dried to a moisture content of ~4% and then placed into The rotary hearth furnace is preheated and reduced, and the atmosphere in the reaction section is controlled to be a reducing atmosphere. The reduction temperature is 1300°C, the rotation speed of the rotary hearth furnace is controlled at 60min / r, and the angle between the rings in the reaction section is 290°C. P-containing 4 The gaseous substa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com