Manufacturing technology of carbon fiber loading rod and carbon fiber loading rod

A manufacturing process and technology of carbon fiber rods, which is applied in the field of automobile engine testing experiments, can solve the problems of low overall strength of carbon fiber rods and loose bonding of carbon fiber rods, so as to avoid economic losses and personal injuries, avoid loose bonding, and improve strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

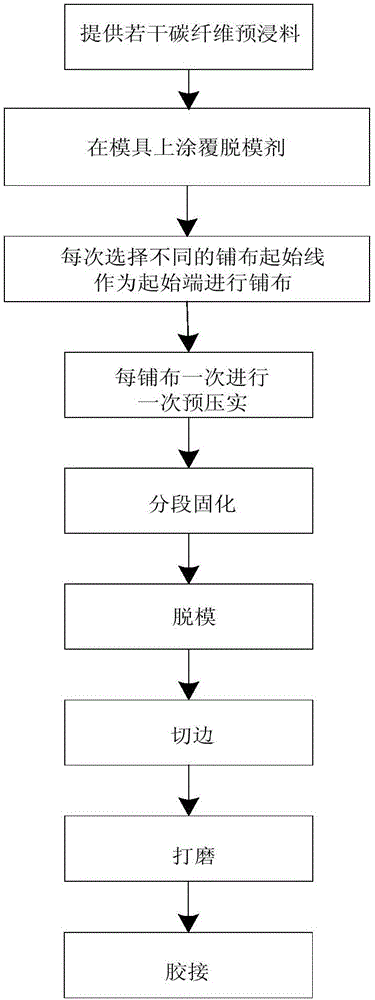

[0038] Such as Figure 1-Figure 3 As shown, Embodiment 1 provides a carbon fiber loading rod manufacturing process, including:

[0039] Step A: Provide a carbon fiber prepreg, the carbon fiber prepreg is T300 carbon fiber prepreg, and the dimension of the prepreg along the length direction forming the carbon fiber loading rod is 585 mm. The tensile strength of T300 is 3450MPa, the tensile modulus is 230GPa, the density is 1.8g / cm3, and the elongation at break is 1.5%. Compared with other metal materials, it has higher strength. In the case of the same volume, It has a smaller mass and is more suitable to be made into parts to meet the lightweight needs of the industry.

[0040] Step B: coating the mold 1 with a release agent, the release agent is a general release agent, which can be zinc stearate, calcium stearate or a combination thereof.

[0041] Step C: spread M layers of prepreg on the mold 1, the number of M is greater than or equal to two, the mold 1 is a pipe body, a...

Embodiment 2

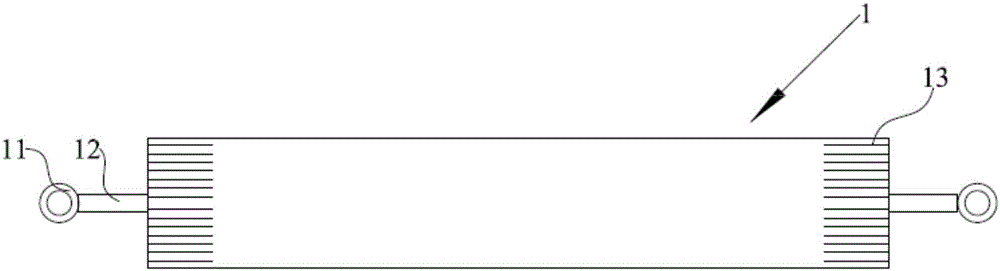

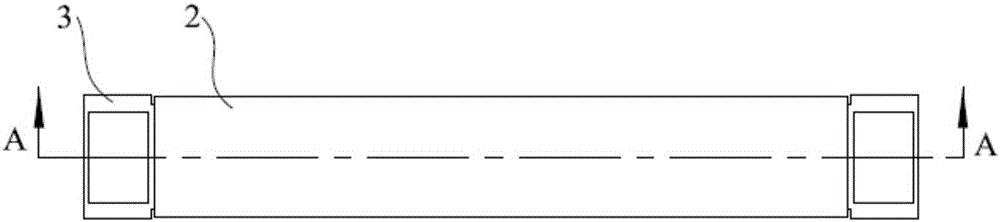

[0053] Such as Figure 2-Figure 4 As shown, Embodiment 2 provides a carbon fiber loading rod, which is manufactured using the carbon fiber loading rod manufacturing process as proposed in Embodiment 1.

[0054] In addition, the carbon fiber loading rod can also be composed of a metal end 3, a metal inner layer and a carbon fiber rod 2. The carbon fiber rod 2 is wrapped on the outer surface of the metal inner layer and fixed by resin connection. The end of the metal end 3 adopts a socket form Connected and fixed to the metal inner layer. The shape of the metal end 3 can be circular or polygonal. According to different occasions and different strengths required by the use of carbon fiber loading rods, the cross-sectional shape of the metal end 3, the metal inner layer and the carbon fiber rod 2 is changed, thereby improving the metal end 3. The connection strength between the metal inner layer and the carbon fiber rod 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com